1

2

3

4

Checking compression pressure

101

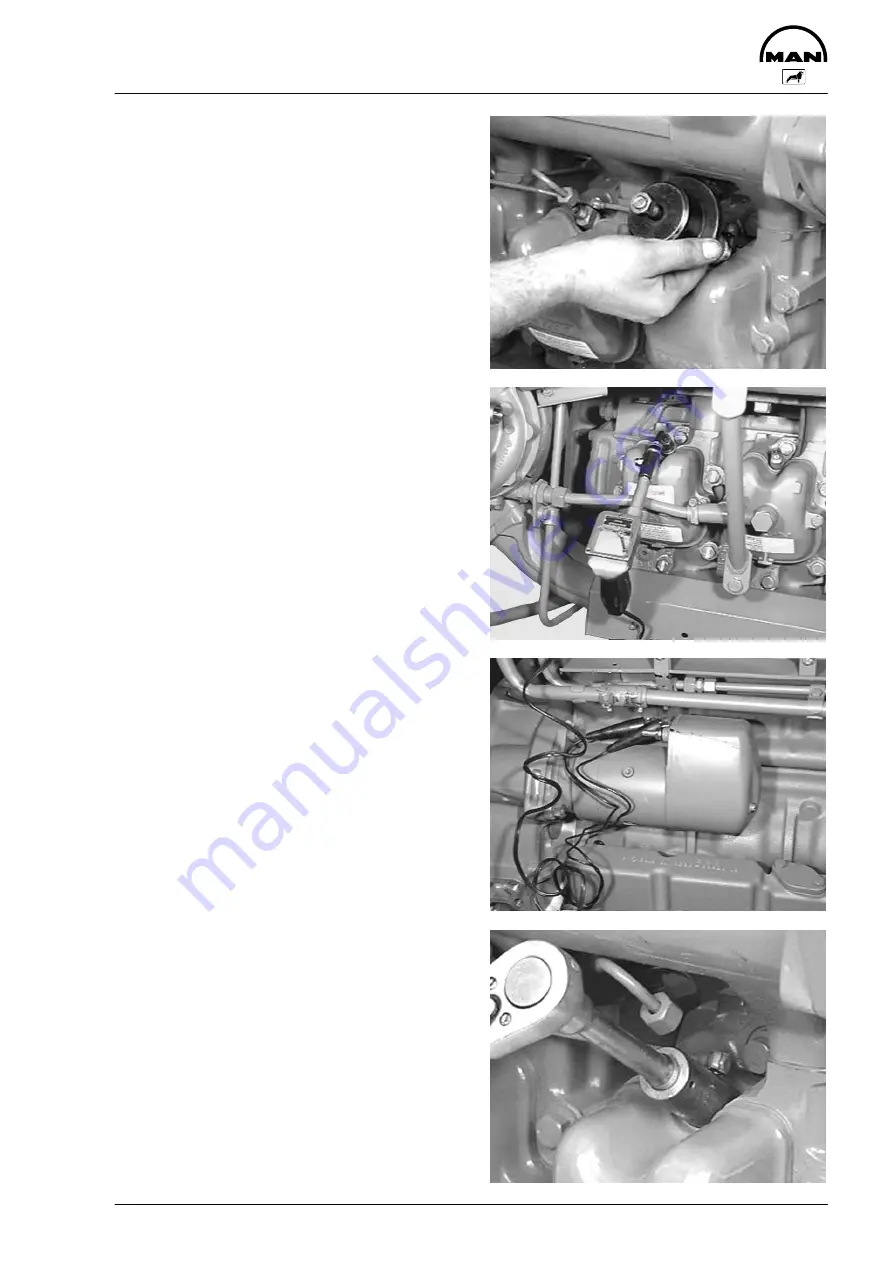

Fig. 1

D

Check valve clearance and adjust, if necessary,

see page 89

D

Let engine run until coolant temperature re-

aches approx. 60-80

°

C

D

Remove all fuel injectors, see page 31

D

For compression guideline values, see publica-

tion “Service Data”

Start with 1st cylinder. Insert new seal, screw on

test connection of compression recorder with union

nut and tighten with pin spanner.

Fig. 2

Screw compression recorder for diesel engines on

to test connection. Insert test sheet into compres-

sion recorder.

Turn engine over by means of starter until the

pointer of the compression recorder is not de-

flected any further.

Connect up compression recorder with test con-

nection to the next cylinder, and check all cylinders

as described above.

Fig. 3

Depending on the compression recorder design,

the engine can also be started directly by the com-

pression recorder.

For this purpose the electrical connections on the

starter electromagnetic switch (terminals 50 and

30) are to be accordingly connected up.

Fig. 4

Compare the values measured and remove com-

pression recorder and test connection. Apply

“Never Seeze” to contact faces on fuel injectors.

Screw in fuel injectors with nozzle and new seal.

Screw on union nut and tighten to specified torque.

Connect up injection lines and leakage fuel return

lines.

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......