9

10

11

Removing and installing / Repairing Oil Pump

64

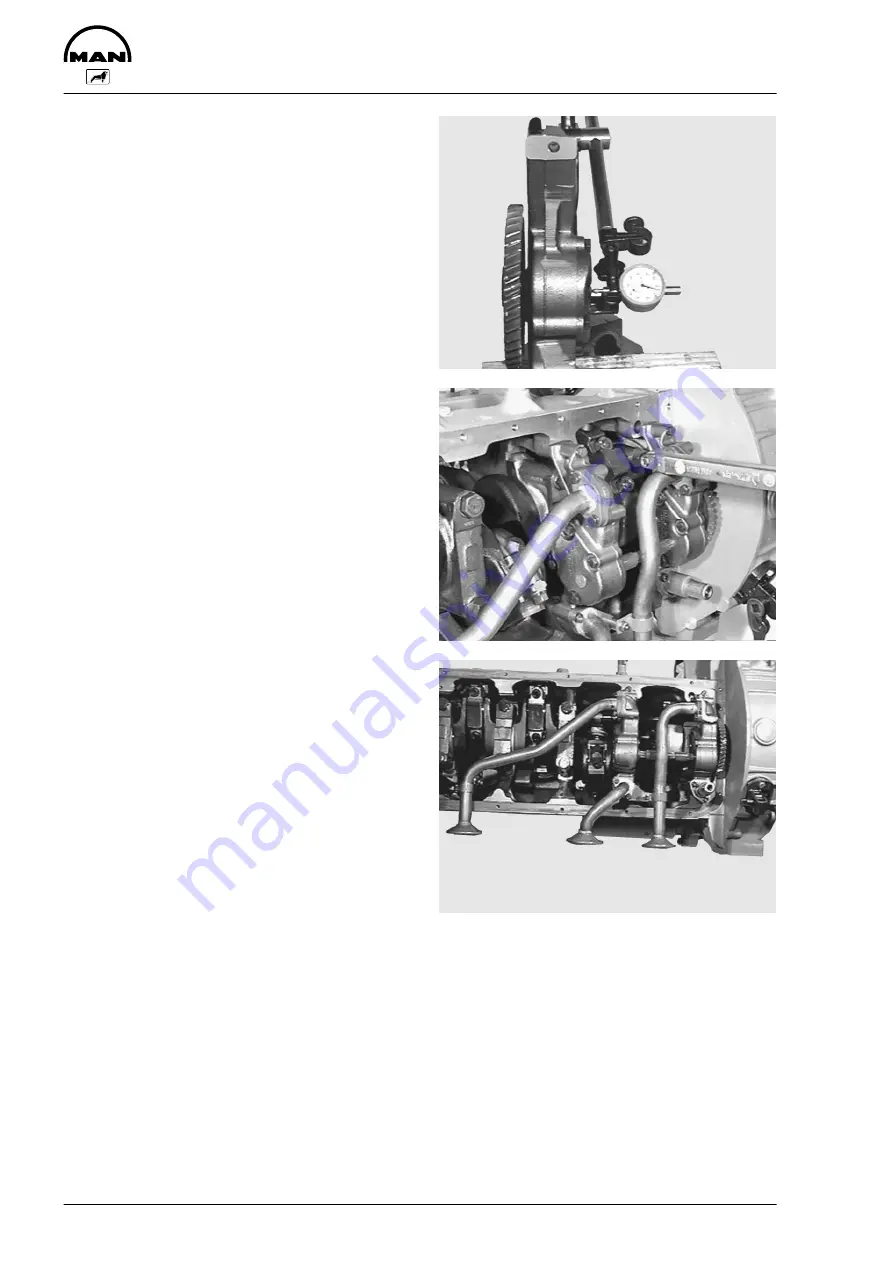

Checking the axial clearance of the

pump wheels

Fig. 9

Attach a dial gauge, push the shaft in one direction

up to the stop and set the dial gauge to “0”.

Push the shaft in the opposite direction and read

off the needle deflection on the dial gauge.

Installing oil pump

Fig. 10

Before installing, check whether the oil pumps runs

smoothly and then fit them free of tension.

Fit oil suction line with seal in a tension-free man-

ner.

Screw on pressure-relief valve without seal.

Tighten the securing bolts with the prescribed tor-

que.

Fig. 11

Before installing the oil pan, crank the engine to

check whether the crank gear and the oil pumps

run unimpeded and smoothly.

Fitting the oil pan

Fill up the engine oil. Check oil level. Check the oil

pan for leaks

Summary of Contents for D 2866 LUE 605

Page 1: ......

Page 2: ......

Page 14: ...Notes 12...

Page 19: ...Memoranda 17...

Page 20: ...Engine views 18 Engine views 3 4 2 1 7 6 5 8 11 10 9...

Page 68: ...Memoranda 66...

Page 133: ...131 Service Data...

Page 157: ...155 Special tools...

Page 158: ...Special tools 156 2 3 4 5 6 7 8 1 6 1 6 2 6 3 9 1 9 2 9 3 9...

Page 162: ...Special tools 160 21 22 25 25 2 24 25 1 26 27 1 27 2 27 20 1 19 2 19 1 20 2 19 20 23 28...

Page 164: ...Special tools 162 30 31 32 1 32 32 2...

Page 167: ...Special tools 165 Pressing mandel for cap dia 62 1 mm Pressing mandel for cap dia 50 1 mm...

Page 170: ...Notes 168...

Page 173: ......

Page 174: ......