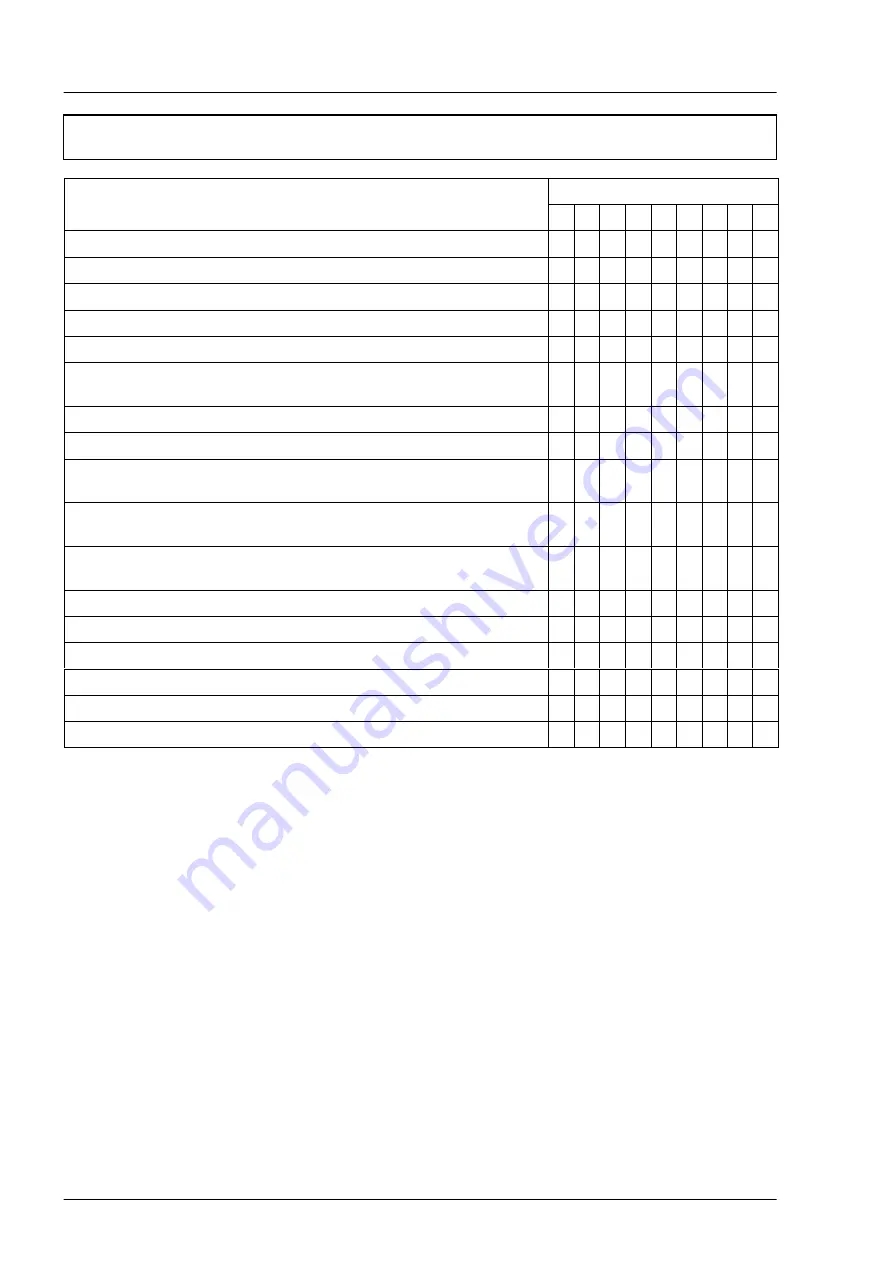

Maintenance chart

42

ALWAYS COMPLY WITH SAFETY REGULATIONS

Maintenance jobs

Maintenance cycles

*

1

2

3

4

5

6

7

8

9

Check coolant level and oil level in engine

D

Check air filter contamination

D

Change engine oil (see also page 43)

D d d d

Change oil filter cartridge (see also page 43)

D d d d

Clean fuel strainer

D D

Draining fuel filter / condensation (earlier if severe operating condi

tions demand it)

D

Check and if necessary correct V-belt tension

D D

1st retightening of cylinder head bolts (with overhauled engine)

D

Check that removable unions (bolts, hose clips, pipe fittings) are firmly

in position and, if necessary, retighten

D D

Service the air cleaner (earlier if severe operating conditions demand

it)

D

2nd retightening of cylinder head bolts (with new or overhauled en

gine)

D

Check and if necessary adjust valve clearance

D

D D

Change disposable fuel filter / filter elements

D

Check turbocharger

D

Change coolant

D

Renew filler cap and working valve of cooling system

D

Check injection nozzles

D

*

1 -

Daily

2 -

After the first 10 to 20 hours of operation (with new or overhauled engine)

3 -

Every 200 hours of operation

4 -

After the first 400 hours of operation

5 -

Every 400 hours of operation

6 -

Every 1000 hours of operation

7 -

Every 3000 hours of operation

8 -

Every 2 years

9 -

Every 6000 hours of operation

d

Change interval in operating hours depends on quality of oil used, see page 43.