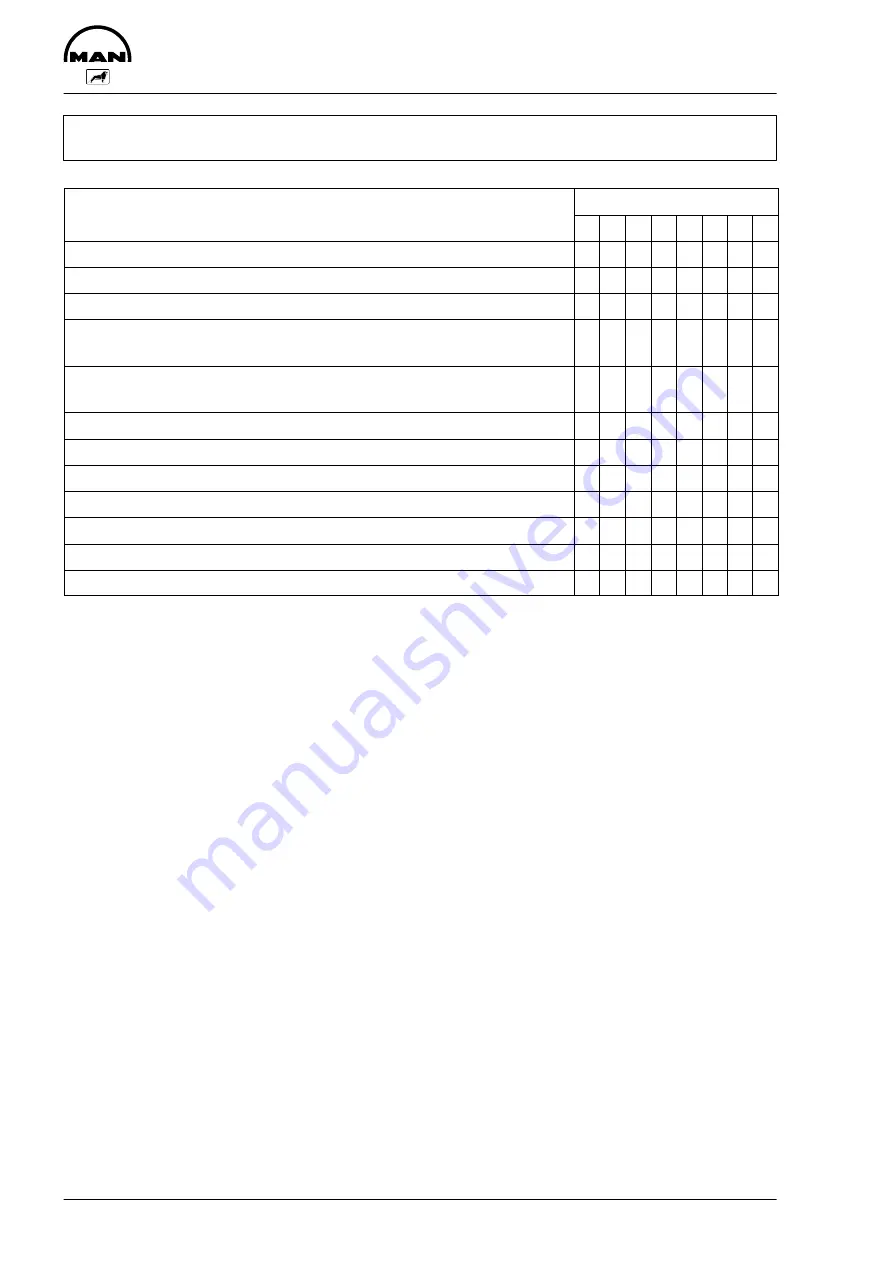

Maintenance chart

38

ALWAYS COMPLY WITH SAFETY REGULATIONS!

Maintenance jobs

Maintenance cycles *

Maintenance jobs

1 2 3 4 5 6 7 8

Check coolant level and oil level in engine

D

Change engine oil in sump

D

D

Change oil filter cartridge

D

D

Check that removable unions (bolts, hose clips, pipe fittings)

are firmly in position and, if necessary, retighten

D

Service the air cleaner

(earlier if severe operating conditions demand it)

D

Check and if neccessary adjust valve clearance

D D D

Change spark plugs

D

Check ignition timing

D

Check comprssion pressure

D

Check anti-freeze concentration

D

Change both valve caps on expansion tank

D

Change coolant

D

1 – Daily

2 – At the first 10 to 20 hours of operation (with new or overhauled engine)

3 – After the first 400 hours of operation

4 – Every 800 hours of operation *)

5 – Every 2000 hours of operation

6 – Every 3 months

7 – Yearly

8 – Every 2 years

* Interval to be reviewed on the strengh of practical experience

Summary of Contents for E 0824 E 301

Page 1: ......

Page 2: ......

Page 14: ...Commissioning and operation 12 Engine views E 0824 E 301 302 1 2 3 4 5 6 7 8 9 10 11 12...

Page 16: ...Commissioning and operation 14 Engine views E 0826 E 301 302 1 2 3 4 5 6 7 8 9 10 11 12...

Page 35: ...Notes 33...

Page 41: ...39 Circuit diagrams...

Page 45: ...Notes 43...

Page 47: ......

Page 48: ......