Conditions

Like fuel, lube oil and engine cooling water, water

for exhaust gas boiler plants is a consumable,

which has carefully to be chosen, treated and

supervised. In the case of improper water mainte-

nance, corrosion and deposits may form up in the

water. Deposits will on their part again result in cor-

rosion and have an adverse effect on heat transfer.

Any additional requirements for water quality speci-

fied in the boiler manufacturer's manual have to be

taken into consideration.

Applications

Two different systems are used:

• Exhaust gas boiler plants generate steam, which

is used as heat transfer agent in other systems.

• With regard to steam turbines, steam generated

by means of the exhaust gas temperature is used

for energy production.

Separate demands made on feed and circulating

water are valid for both application cases.

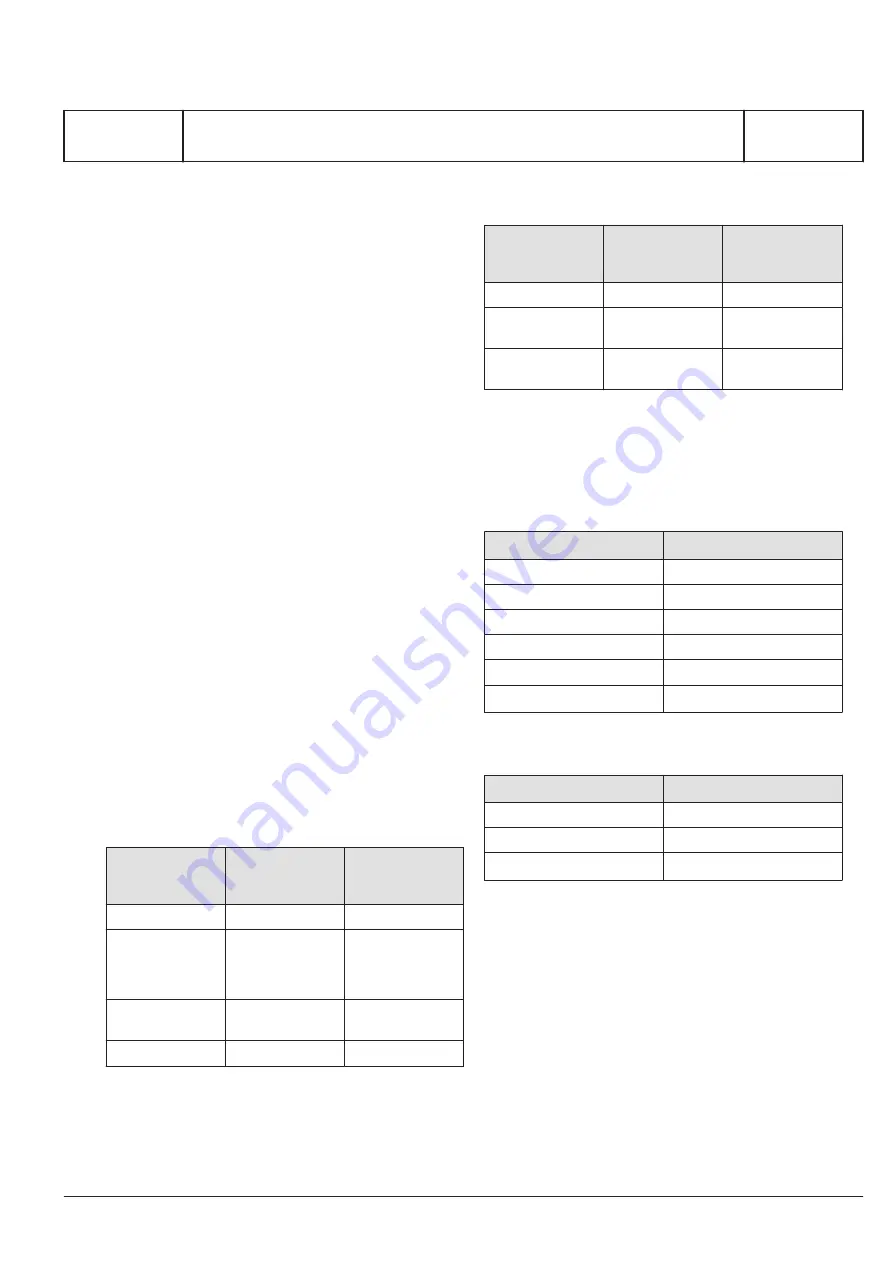

Exhaust gas boiler without steam turbine

The quality requirements for feed and circulating

water comply with TRD 611 (Technische Regeln für

Dampfkessel = technical rules for steam boilers).

Low-salt and salt-laden feed water can be used if

the specifications in

Table 1, are kept. The utilisa-

tion of the salt-free feed water is possible, but not

necessary. When using saltless feed water, corre-

sponding limit values are valid for circulating water.

Saltless

feed water

Low-salt or

salt-laden

feed water

pH value at 25

o

C

> 9

> 9

Hardness

< 0.06 ûdH

resp.

< 0.01 mmol/l

Conductivity at

25

o

C

< 0.2 µS/cm

1)

Oxygen content

< 0.1 mg/l

< 0.02 mg/l

Table 1: Requirements for feed water in exhaust gas boilers

1) After strongly acid sample drawing cation

exchanger

Saltless

circulating water

Low-salt or

salt-laden

circulating water

pH value at 25

o

C

9.5 - 10.5

10.5 - 12

Conductivity at

25

o

C

< 50 µS/cm

< 5000 µS/cm

Acid capacity up

to pH 8.2

1 - 12 mmol/l

Table 2: Requirements for circulating water in exhaust gas boiler

Exhaust gas boiler with steam turbine

Only saltless feed water, which complies with the

requirements

according to Table 3, may be used for

steam turbines.

Saltfree feed water

pH value at 25

o

C

> 9

Conductivity at 25

o

C

< 0.2 µS/cm

1)

Oxygen content

< 0.1 mg/l

Iron, total Fe

< 0.03 mg/l

Copper, total Cu

< 0.005 mg/l

Silicic acid, SiO

2

< 0.02 mg/l

Table 3: Requirements for feed water in steam turbines

1)

After strongly acid drawing cation exchanger

Saltfree circulating water

pH value at 25

o

C

9.5 - 10.5

Conductivity at 25

o

C

< 3 µS/cm

Silicic acid, SiO

2

< 4 mg/l

Table 4: Requirements for circulating water in steam turbines

Treatment

The feed water has to be treated with suitable

chemicals. If an exhaust gas boiler without turbine is

used, the conditioning agent must contain the fol-

lowing products:

• Residue softener

• Oxygen binder

• Alkalising medium

• Steam-volatile alkalising medium for corrosion

protection in the condensate system (not compul-

sorily required in the case of saltless feed water)

MAN Diesel & Turbo

1699251-7.0

Page 1 (2)

Quality of water used in exhaust gas boiler plants

B 13 00 0

L28/32S, L27/38S, L23/30S, L21/31S, L16/24S, V28/32S, L16/24, L21/31,

L23/30H, L27/38, L28/32H

2008.10.27

Summary of Contents for L23/30DF

Page 1: ...L27 38S Project Guide Power Plant Four stroke GenSet...

Page 2: ......

Page 8: ......

Page 9: ...MAN Diesel Turbo I 00 Introduction Page 1 1 I 00 Introduction 2018 04 13 en...

Page 10: ......

Page 14: ......

Page 16: ......

Page 20: ......

Page 31: ...MAN Diesel Turbo D 10 General information Page 1 1 D 10 General information 2018 04 13 en...

Page 32: ......

Page 40: ......

Page 42: ......

Page 46: ......

Page 48: ......

Page 50: ......

Page 59: ...MAN Diesel Turbo B 10 Basic diesel engine Page 1 1 B 10 Basic diesel engine 2018 04 13 en...

Page 60: ......

Page 68: ......

Page 70: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 82: ......

Page 84: ......

Page 85: ...MAN Diesel Turbo B 11 Fuel oil system Page 1 1 B 11 Fuel oil system 2018 04 13 en...

Page 86: ......

Page 104: ......

Page 114: ......

Page 118: ......

Page 126: ......

Page 128: ......

Page 130: ......

Page 134: ......

Page 138: ......

Page 142: ......

Page 173: ...MAN Diesel Turbo B 13 Cooling water system Page 1 1 B 13 Cooling water system 2018 04 13 en...

Page 186: ......

Page 192: ......

Page 198: ......

Page 202: ......

Page 204: ......

Page 207: ...MAN Diesel Turbo B 14 Compressed air system Page 1 1 B 14 Compressed air system 2018 04 13 en...

Page 210: ......

Page 216: ......

Page 217: ...MAN Diesel Turbo B 15 Combustion air system Page 1 1 B 15 Combustion air system 2018 04 13 en...

Page 218: ......

Page 224: ......

Page 226: ......

Page 227: ...MAN Diesel Turbo B 16 Exhaust gas system Page 1 1 B 16 Exhaust gas system 2018 04 13 en...

Page 228: ......

Page 252: ......

Page 256: ......

Page 269: ...MAN Diesel Turbo B 17 Speed control system Page 1 1 B 17 Speed control system 2018 04 13 en...

Page 270: ......

Page 272: ......

Page 282: ......

Page 284: ......

Page 286: ......

Page 293: ...ENGINE AUTOMATION MAN Diesel Turbo SE SaCoSone GENSET System description Revision 1 5...

Page 306: ...MAN Diesel Turbo SaCoSone GENSET SaCoSone GENSET Communication from GenSet Revision 1 7...

Page 309: ...MAN Diesel Turbo Table of Contents...

Page 324: ......

Page 326: ......

Page 327: ...MAN Diesel Turbo B 20 Foundation Page 1 1 B 20 Foundation 2018 04 13 en...

Page 328: ......

Page 334: ......

Page 335: ...MAN Diesel Turbo B 21 Test running Page 1 1 B 21 Test running 2018 04 13 en...

Page 336: ......

Page 341: ...MAN Diesel Turbo E 23 Spare parts Page 1 1 E 23 Spare parts 2018 04 13 en...

Page 342: ......

Page 348: ......

Page 350: ......

Page 351: ...MAN Diesel Turbo P 24 Tools Page 1 1 P 24 Tools 2018 04 13 en...

Page 379: ...MAN Diesel Turbo B 50 Alternator Page 1 1 B 50 Alternator 2018 04 13 en...

Page 380: ......

Page 386: ......

Page 390: ......

Page 392: ......