Aligning an engine with flange−mounted gearbox

29

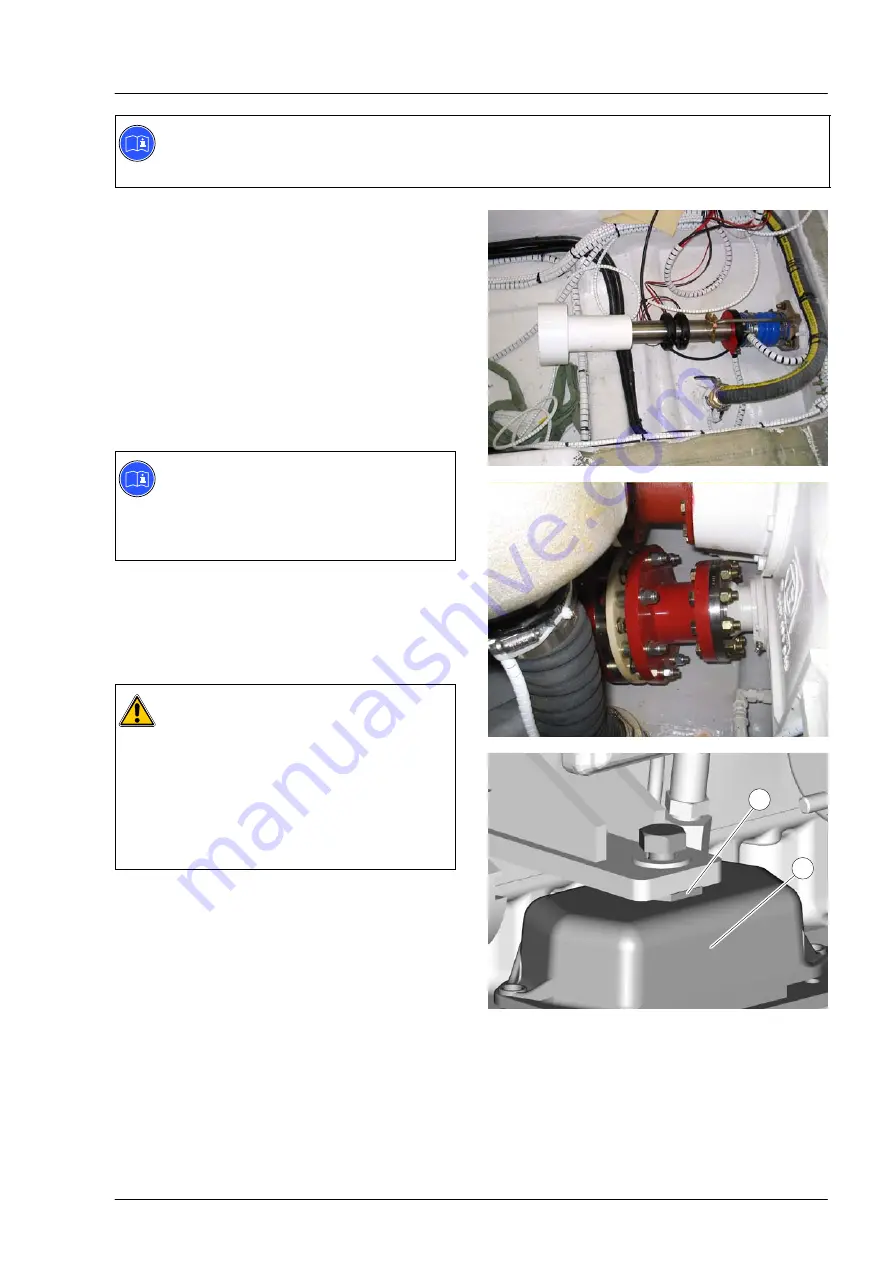

Note:

The mounts are pre−compressed at the factory by the shipping locks. For this reason it is not

necessary to preload the resilient mounts before the alignment.

Provisionally aligning drive line

D

Place the drive line and the resilient mounts

onto the engine foundation using suitable crane

lifting equipment.

D

Raise the propeller shaft by hand at the

coupling flange as far as possible.

Half the angle between the highest and lowest

positions of the coupling flange provides the

correct height for the gearbox output flange.

This ensures that the propeller shaft can be

correctly centred.

Note:

A resilient propeller shaft coupling between

gearbox output flange and propeller shaft

flange compensates minor offset and

reduces vibrations.

D

Align gearbox output flange and propeller shaft

flange flat with the aid of suitable surfaces.

D

Adjust the height

À

of the engine mounts

Á

. In

so doing, ensure that the mounts are equally

compressed on both sides of the engine.

Caution:

The max. height adjustment of all mounts

is 10 mm.

This adjustment height must not be

exceeded. Larger differences in height

must be compensated for with metal

shims.

The less the height is adjusted, the more

room for later adjustments.

1

2

Summary of Contents for V12-1800

Page 1: ......

Page 2: ......

Page 12: ...Planning of engine installation 10 V12 1800 1 2 3 4 5 V8 1200 6 7 8 9 4 10 11...

Page 78: ...Notes 76...

Page 79: ...77 Appendix...

Page 80: ......

Page 91: ......

Page 92: ......