17

the anchor plate assembly must be coated

with inner joint sealant.

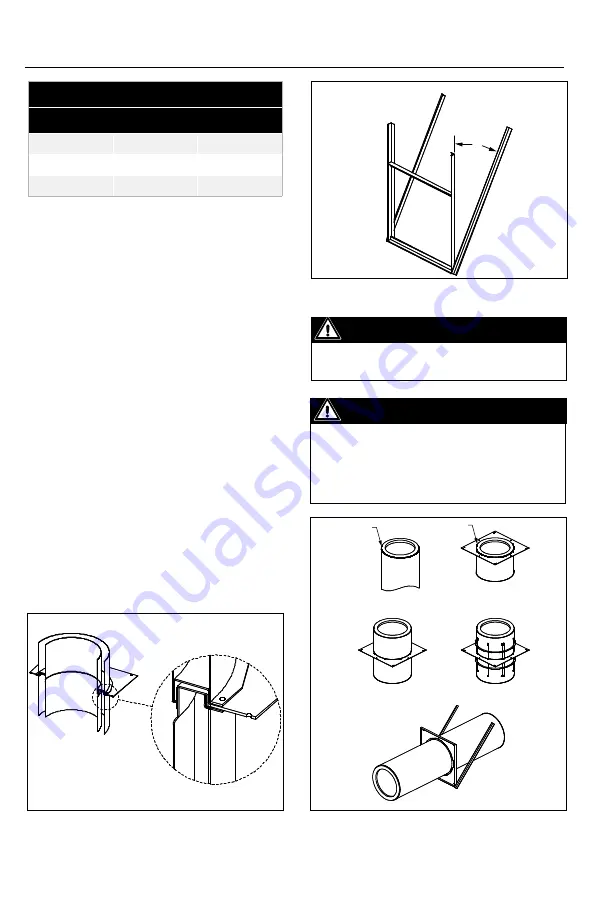

6. There are two ways of assembling parts on

the support. You may choose your method

depending on your situation.

6.1 The first method consists of assembling

two parts and the anchor plate on the side

and then installing this assembly on the

support structure. This method is easier

and faster to install, but requires enough

clearance to insert the complete assembly

through the support structure opening.

If there is a tee or elbow upstream of the

anchor plate, you may not have enough

clearance. Also consider the weight of the

assembled parts and make sure you have a

safe manner of lifting the assembly.

Installation Steps for First method (refer to

Figure 22)

1. Place the part that will be upsteam of the

support on the floor.

2. Apply a bead of inner joint sealant on the

male coupling flange.

Figure 20

Figure 21

Important

If bracing is used, minimum “X” angle is 30°.

If there is no bracing, the framework

must be attached to structural members to

provide equivalent rigidity.

Important

Height Limits - See Section a, table 6 for

maximum support height of Anchor Plate (AP).

Figure 22

Table 12

Bracing DIS/DAS

I.D.

Framework

Bracing

5" - 20"

3" x 2" x 3/16"

2" x 2" x ¼"

22" - 36"

4" x 2" x ¼"

3" x 3" x ¼"

"X"

Sealant

Bead

Sealant

Bead

Method #1-

Step 1 and 2

Method #1-

Step 3 and 4

Method #1-

Step 5

Method #1-

Step 6

Method #1-

Step 7