36

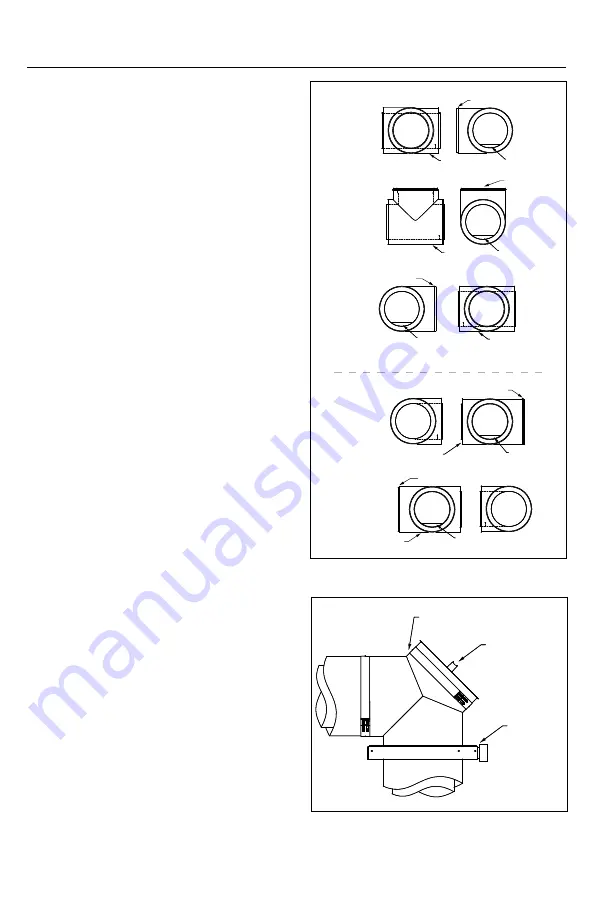

Figure 70

Figure 71

(TC). The location of the access port in the tee

is dependent on the orientation of the tee in

the final installation. Access port location is

coded as shown in Figure 70.

grEaSE tEE y (DIS onLy)

1. The Grease Tee Y (GTY) is very useful where

the grease duct must be accessed for clean-

out and inspection purposes. See Figure 71.

2. It can be used in place of the Grease Tee

90 (GT90) and provides excellent access

clearance for clean-outs.

3. Clean-outs must be located at all direction

changes in the grease ductwork.

4. Installation is the same as standard tee.

no tooL aCCESS Door - rEmoVaL For

InSpECtIon or CLEanIng

1. Unscrew the six (6) wing screws with your

hands and set them in a safe place during the

inspection (See Figure 72).

2. Remove the outer door from the outer wall

of the duct and set it in a safe place during

the inspection (See Figure 73).

3. Remove the insulation pad and set it in a

safe place during the inspection (See

Figure 73).

4. Unscrew the eight (8) wing screws and set

it in a safe place (See Figure 74).

5. Remove the Inner cover and set it in a safe

place (See Figure 74).

6. Inspect the ceramic gasket (white) and the

silicone gasket (gray) attached on the inside

of the Inner door for any damage (See Figure

75). If any damages, you must order one or

both gaskets.

replacement of the access door:

1. Replace the Inner door on the duct over

the access hole.

2. To make sure the door is well placed, put

back only the top and lower central wing

screw and tighten both.

3. Make sure that the door is well placed.

4. Put back the other six (6) wing screws and

tighten adequately.

Male Coupling

Grease dam

Position #1

Grease Tee

Position #1

Male Coupling

Grease dam

Position #2

Grease Tee

Position #2

Grease Tee

Position #3

Grease dam

Position #3

Standard Tee With

Dam Position #1

Grease dam

Male Coupling

Grease dam

Standard Tee With

Dam Position #2

Grease Tee Y

Tee Cap

Support