MANDÍK CPV Installation, commissioning, and maintenance

IZU 02/2021

MANDÍK, a.s., www.mandik.cz

R

16

blocks of the unit or the heat exchangers. Connections must be executed so that expansion of

the piping as a result of temperature changes does not result in excessive loading of the

ports.

Two wrenches must be used to tighten connections. Thread deformation is a significant risk

otherwise!

A vent valve, if installed, must be located at the highest point on the hot / cold water supply

line.

Always connect heat exchangers in a counter-flow configuration!

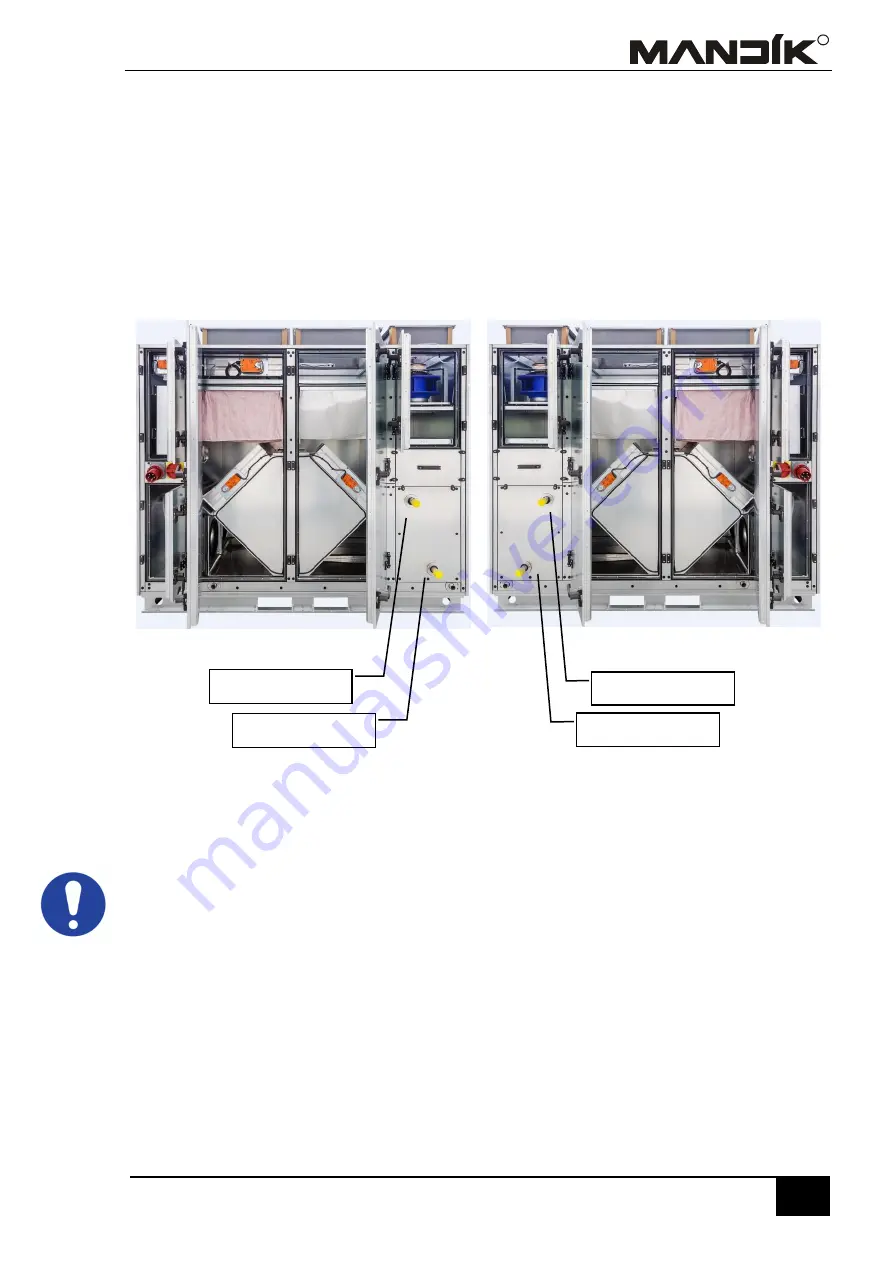

Fig 5 Right-hand unit configuration

Fig 6 Left-hand unit configuration

A capillary freeze-protection thermostat is integrated into the unit, fully installed and

connected to the control system from the factory.

The mixing loop for heat control, if part of delivery, is provided in a separate cardboard box.

The installation and service manual is attached to the mixing loop packaging. The manual

provides detailed information on safe installation, commissioning, and maintenance.

Water supplying the heat exchangers must be treated to remove contaminants that cause

fouling, especially those that corrode steel and cast iron components. The water must be

chemically treated to the parameters specified in ČSN 07 7401 to prevent this c

ontamination.

•

Hydrogen exponent pH 7 - 9.

•

Water hardness 1.0 mval.l

-1

.

•

Chloride content, max. 30 mg.l

-1

.

MEDIA INPUT

MEDIA OUTPUT

MEDIA INPUT

MEDIA OUTPUT