MANDÍK CPV Installation, commissioning, and maintenance

IZU 02/2021

MANDÍK, a.s., www.mandik.cz

R

31

1

3

6

12

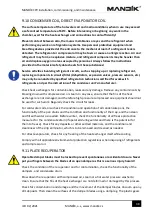

2. FILTERS G2-F9, GREASE

2.01.

Y

value from the

measuring and

control system

2.02.

N

replacement

2.03.

N

repair

2.04.

Y

repositioning/r

eplacement

2.05.

N

repair

* status of unit operation while performing the checks

Check the filter pressure losses.

Check the fitting of pressure probes for

measuring filter differential pressure.

Check the integrity of the filtration medium of

the filter elements.

Check the integrity of the filter holder sealing

profiles and the seal between the filter elements.

Check the setting and function of the differential

pressure gauge (switches, digital, sloping tube).

SERVICING AND MAINTENANCE OPERATIONS

Unit in

operation

Y/N *

Check operation

Service/rectificati

on method

Intervals (months)

1

3

6

12

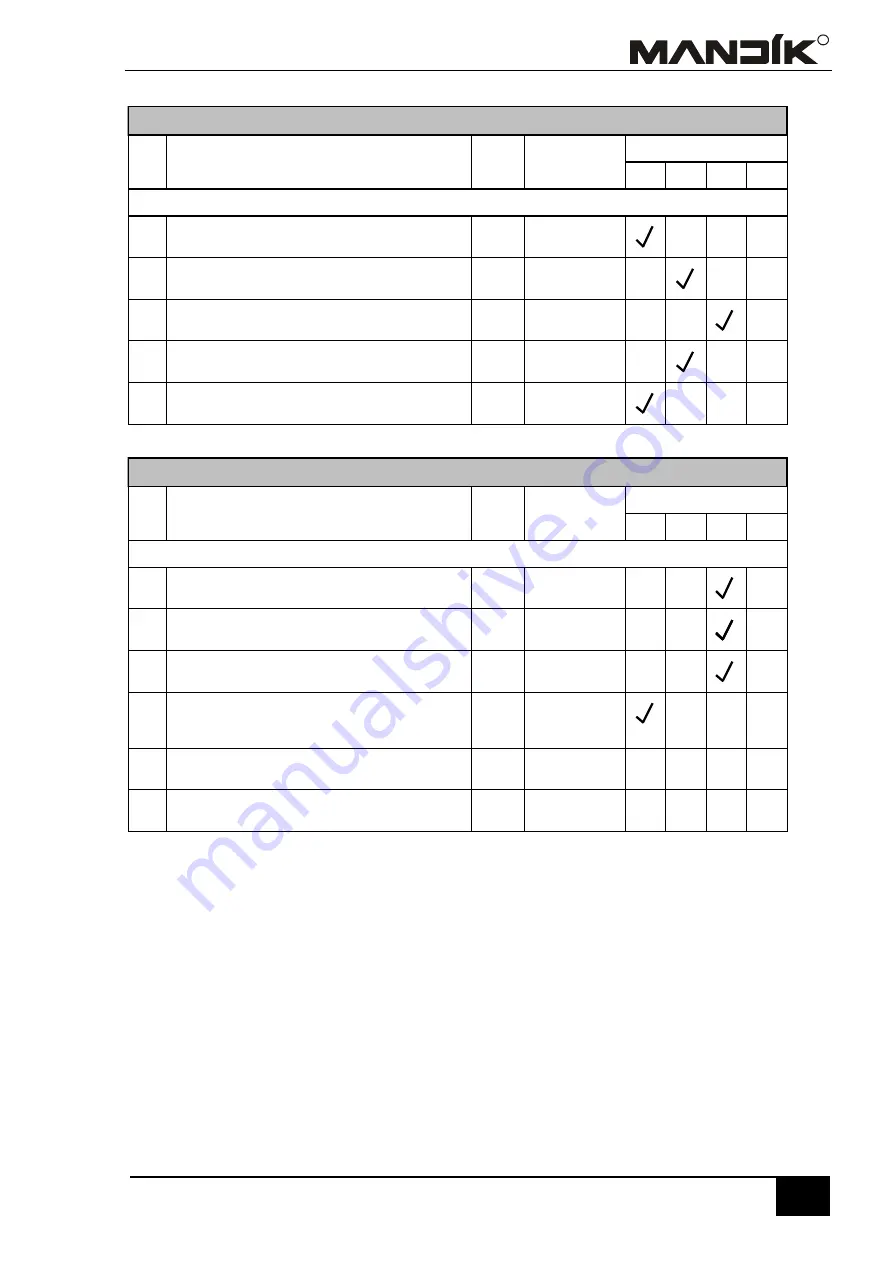

3. FANS WITH FREE IMPELLERS

3.01.

N

cleaning

3.02.

N

repair

3.03.

N

repair

3.04.

Y

repair

3.05.

3.06.

* status of unit operation while performing the checks

Check the assembly for excessive vibrations –

the assembly must not show any visible

vibrations.

Check the impeller for free rotation.

Service/rectificati

on method

Tighten the cables in the electric motor terminal

board.

Intervals (months)

SERVICING AND MAINTENANCE OPERATIONS

Unit in

operation

Y/N *

Check operation

Check the cleanness and condition of the

impeller and the chamber inside.