14

TPM 092/13

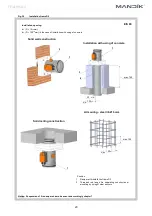

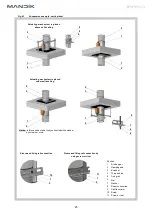

Tab. 6.1.1. Statement of installations

Size

FDMD installation

Classification

Figure

100-200

Damper installed in a solid wall construction min. thickness 100 mm.

Space between damper and wall is filled by mortar or gypsum (notice 1)

EIS 120

EIS 90

25

Damper installed in a solid wall construction min. thickness 100 mm.

Space between damper and wall is filled by mineral stone wool min.

density 140 kg/m ). Surface is covered by fire protection

mastic min. thickness 1 mm (notice 1)

EIS 90

26

Damper installed in a solid wall construction min. thickness 100 mm.

Space between damper and wall is filled by system Weichshott (notice 1)

EIS 90

27

Damper installed in a gypsum wall construction min. thickness 100 mm.

Space between damper and wall is filled by mortar or gypsum (notice 3)

EIS 120

EIS 90

28

Damper installed in a gypsum wall construction min. thickness 100 mm.

Space between damper and wall is filled by mineral stone wool min.

density 140 kg/m ). Surface is covered by fire protection

mastic min. thickness 1 mm (notice 3)

EIS 90

29

Damper installed in a gypsum wall construction min. thickness 100 mm.

Space between damper and wall is filled by system Weichshott (notice 3)

EIS 90

30

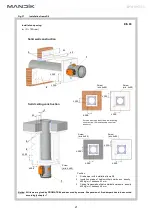

Damper installed in a solid ceiling construction min. thickness 100 mm.

Space between damper and wall is filled by mortar or gypsum (notice 2)

EIS 120

EIS 90

31

Damper installed ina solid ceiling construction min. thickness 100 mm.

Space between damper and wall is filled by mineral stone wool min.

density 140 kg/m ). Surface is covered by fire protection

mastic min. thickness 1 mm (notice 2)

EIS 90

32

Damper installed in a a solid ceiling construction min. thickness 100 mm.

Space between damper and wall is filled by system Weichshott (notice 2)

EIS 90

33

Damper installed in a solid wall construction min. thickness 100 mm, in a

gypsum wall construction min. thickness 100 mm or solid ceiling

construction min. thickness 150 mm. For instalation is used installation

frame D1 or D2.

EIS 90

34

Damper installed in a solid wall construction min. thickness 100 mm, in a

gypsum wall construction min. thickness 100 mm or solid ceiling

construction min. thickness 150 mm. For instalation is used installation

frame D3 or D4.

EIS 90

35

Damper installed on a solid wall construction min. thickness 100 mm or on

a solid ceiling construction min. thickness 150 mm. For instalation is used

installation frame D5.

EIS 90

36

Damper installed outside a solid wall construction min. thickness 100 mm

or outside a solid ceiling construction min. thickness 150 mm. For

instalation is used installation frame D6 and kalciumsilkat boards.

EIS 90

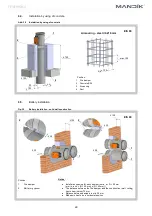

37

Damper installed outside a solid ceiling construction min. Thickness

150 mm. For instalation is used concrete.

EIS 90

38

Dampers installed on a solid wall construction min. thickness 100 mm.

Dampers are placed in battery and space between dampers and wall is

filled by mortar or gypsum.

EIS 90

39

Dampers installed in a gypsum wall construction min. thickness 100 mm.

Dampers are placed in battery and space between dampers and wall is

filled by mortar or gypsum.

EIS 90

40

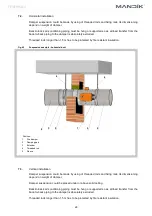

NOTICE:

1) Solid wall construction: normal concrete/masonry or porous concrete with minimum thickness 100 mm

2) Solid ceiling construction: normal concrete/masonry or porous concrete with minimum thickness 150 mm

3) Installation in gypsum wall construction: Installation opening has to be reinforced around the perimeter by standard

profile used for gypsum wall constructions.

6. Statement of installations

6.1.

Statement of installations

3

3

3