3

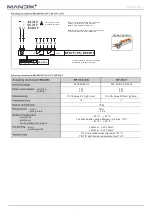

Servo drives with different torque strengths are used according to damper size. Two different servo finished products can be used,

Belimo and Gruner. When Belimo actuators are used they are marked: (230V) BFL, BFN, BF 230-T or (24V) BFL, BFN, BF 24-T

(hereinafter "servo") and when Gruner products are used their marking is (230V) 340TA-230D-03-S2/8F12, 340TA-230-05-

S2/8F12, 360TA-230-12-S2/8F12, 360TA-230-20-S2/8F12 or (24V) 340TA-024D-03-S2/8F12, 340TA-024-05-S2/8F12, 360TA-

024-12-S2/8F12, 360TA-024-20-S2/8F12. Actuators feature reverse spring loaded movement by 90°and include thermo-electric

actuation devices reacting to tempe72°C. Having been connected to 24 V or to 23 V AC/DC power supply respectively

this device sets damper blade to working position OPEN and at the same time it switches over its own check spring. During the

time when servo is under voltage, damper blade is in the position OPEN and check spring is tensioned. Time for complete opening

of damper blade from CLOSED position to OPEN is max. 60s If servo powering is interrupted (by loss of supply voltage or by

pressing reset button on thermo-electric actuator BAT or when temperature e72°C), the check spring sets damper blade

to emergency position CLOSED. Time for complete changeover of damper blade from OPEN position to CLOSED is max. 20 s.

If supply voltage is restored (the blade may be in any position) servo starts to set the blade again to the position OPEN. This new

opening of the damper does not occur spontaneously after restoration of supply voltage if fuses Tf1 and Tf2 have been activated

(Tf1 with exceeding temperature in damper environment, Tf2 with exceeding of temperature inside air condition duct).

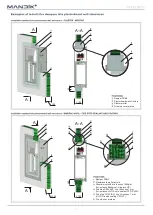

Damper frame is made from galvanized sheet metal.

Covering protection grills (similar to type KMM) are produced from sheet iron and coated with baking varnish in colour RAL 9010.

Requirements for other colours must be discussed with manufacturer in advance.

Damper blades are made from asbestos-free fire protective plates from mineral fibres.

Closing mechanism is zinc-coated. Coupling elements are zinc-coated.

Summary of Contents for FDML

Page 1: ......