4

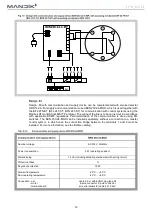

Design .01 with mechanical control can be complemented with a limit switch signalling of the

damper blade position "CLOSED". Cable is connected directly to limit switch.

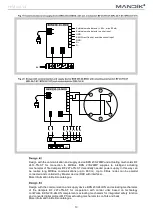

Design .01 with mechanical control can be complemented with a terminal switches signaling of

the damper blade position "CLOSED" and "OPEN". Limit switches are connected via damper

casing, cables are connected directly to limit switches.

Limit switch

“CLOSED”

Limit switch

“CLOSED”

Limit switch

“CLOSED”

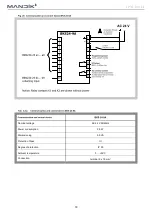

Mechanisms are produced in five designs

to

,

difference is only in size of inner spring, which closes

the fire damper. For the size of fire dampers is always

assigned the size of mechanism -

It is not

recommended to use different size of mechanism,

than given by the manufacturer, otherwise, there is a

risk of fire damper destruction.

Design with mechanical control with a thermal protective fuse which actuates the shutting device,

after the nominal start temperature 72°C has been reached. Automatic initiation of the shutting

device is not activated if the temperature does not exceed 70°C. In case that other start

temperatures are required, thermal fuses with nominal start tempe104°C or +147°C can

be supplied (this requirement must be specified in the order).