60

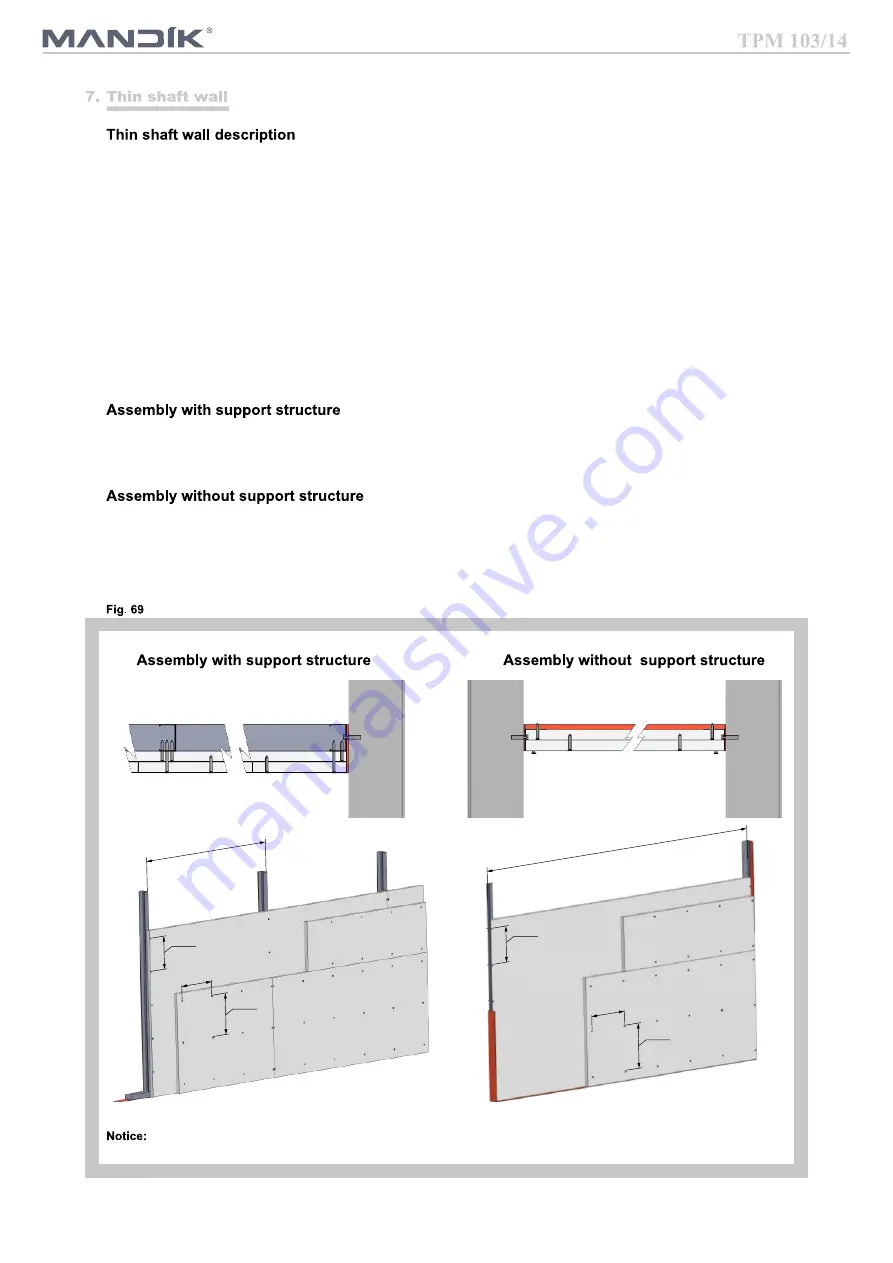

Shaft wall is a vertical, non-bearing partition construction meeting the double-sided fire requirements. The

shaft wall can be mounted only from one side. No mineral insulation is used in the construction.

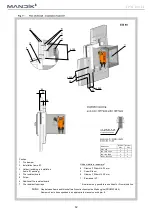

First of all, the shaft wall structure must be laid out. Apart from other vertical constructions, the perimeter

sections must be fitted with connection sealing made from A1 or A2 fire reaction materials (for instance

floor strips Orsil N/PP). The perimete

r sections must be anchored using steel plugs Ø 6 mm (for example

DN6 or ZHOP) with 500 mm span.

Sheathing is carried out using two layers of Glasroc F boards Ridurit with 20 mm thickness, the boards are

oriented horizontally. First sheathing layer is fixed with TN 212 screws in spacing 200mm to the support

structure. The boards are mounted to tight butt joints without need of cementing. The second sheathing

layer is screwed to the first sheathing layer using screws Rodurit in square net 250 mm. Reset of joints of

the first and second layer of Ridurit sheathing is set to 600 mm vertically and 300 mm horizontally.

Vertical intermediate R-CW sections are fixed in 1000 mm layout spacing between R-UW sections and

vertical perimeter R-CW sections.

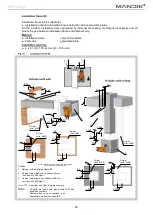

Maximum width of the shaft wall is 2 metres in this case (board length). Steel squares made from steel

galvanized plate metal 40/20/1 mm are used as perimeter sections, they are anchored to bearing wall using

Ø 6 mm steel plugs (for example DN6 or ZHOP) with 500 mm spacing

.

250

200

1000

250

200

max. 20

00

250

250

Rigips solution is shown here as an example. Alternatively it is possible to apply the solution from Knauf or Promat. In

such a case follow the instructions of the producer.