SEDM-L - Smoke extraction damper - multi

Page 16

Version 2022-12-20

TPM 157/22

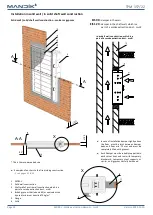

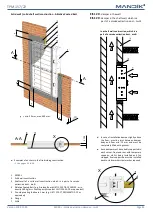

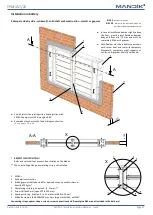

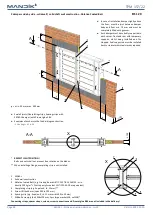

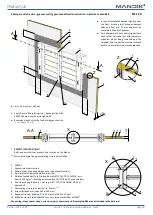

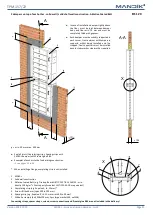

Placement and Assembly

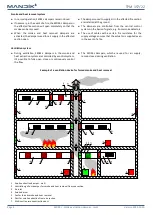

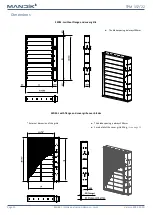

Multi-blade smoke and heat dampers - multi SEDM-L

■

Dampers are designed to remove heat and combustion products (e.g. smoke) from fire compartments according EN 12101-8.

■

They're suitable for installation in a vertical position, with the blade axis horizontal.

■

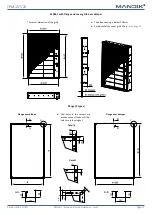

Dampers and duct must be suspended separately. The connected ducting must be supported in such a way that the transfer

of all loads from the adjoining ventilation duct to the damper body is completely excluded. Adjacent duct must be suspended

or supported, as required by the duct suppliers.

■

To provide the necessary space for access to the control device, it is recommended that other objects be at least 350 mm away

from the control parts of the damper.

Transport to the installation site

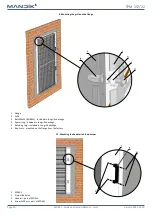

■

Transport the damper to the installation site in the transport packaging. Pay attention to the appropriate length of the forks

of the forklift /handling equipment/ to avoid breaking of wooden planks, consequently damaging the damper´s blades.

■

Smaller dimensions can be transported, handled and installed into the builders work opening manually, for dimensions where

a handling insert is included in the delivery, it is recommended to use a suitable handling tools and machines, e.g. a forklift.

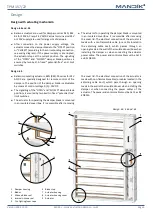

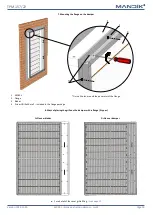

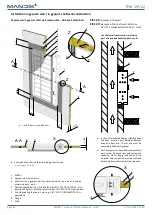

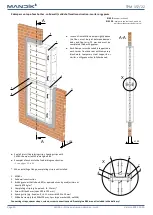

Damper handling when installed in the mounting hole

1. Place the damper in a vertical position. Do not remove the transport pacers and corners!

2. Place handling inserts between the top blade and the damper housing.

3. Drive the forklift under the highest blade. It’s necessary to put a board between the blade and the fork along the blade’s entire length

so that the blade is not damaged when the damper is raised.

Handling inserts

only 1 set required per delivery

1

Damper housing

2

Blade stop

3

Handling inserts (2pc)*

4

Blades

5

Board - not included**

6

Forks

* Included in package of larger dimensions SEDM-L.

** Construction board thickness min. 25 mm.