SEDM - Smoke extraction damper - multi

Page 56

Version 2022-12-20

TPM 156/22

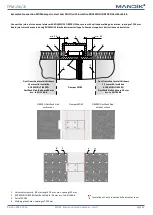

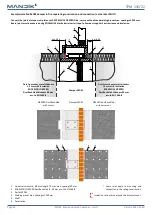

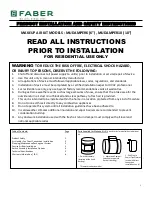

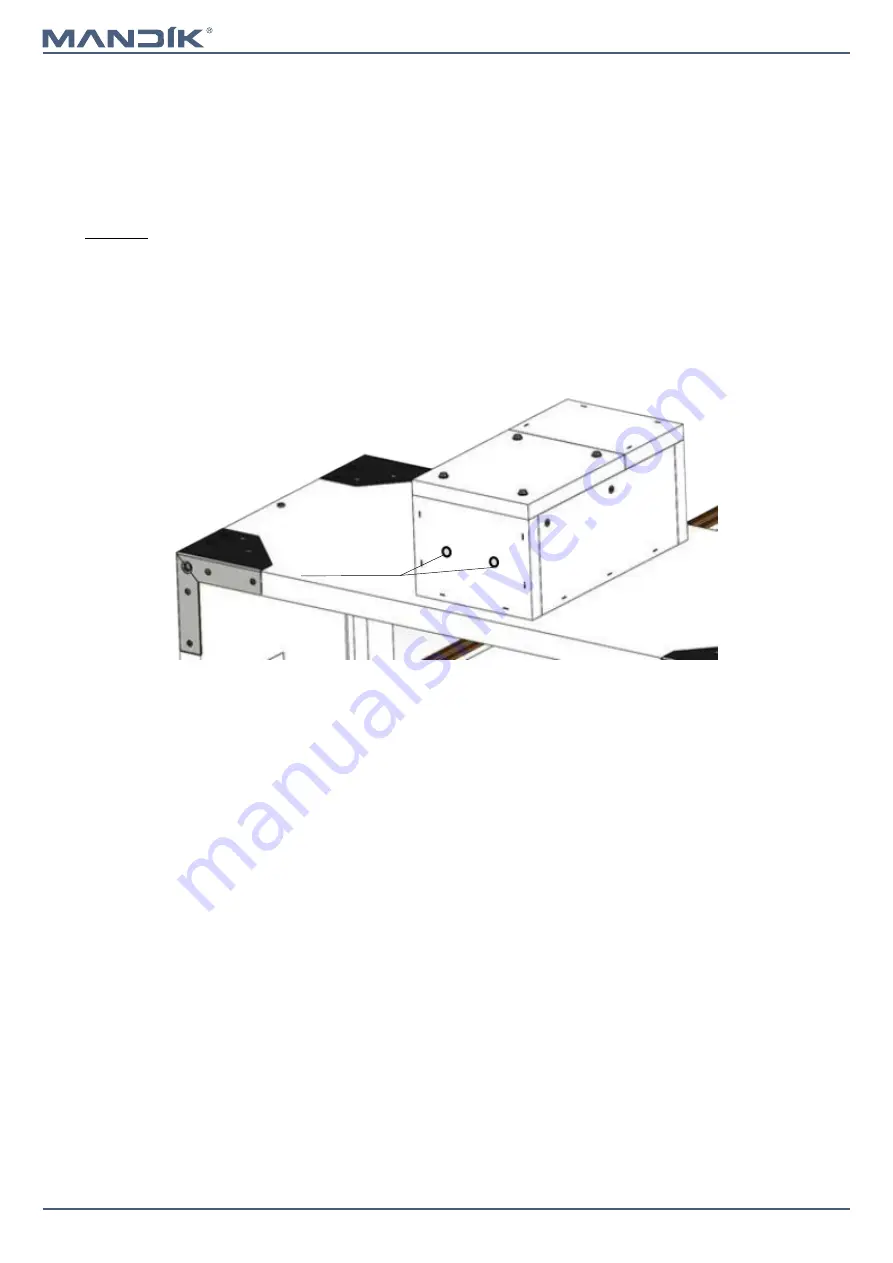

Electrical connection of the actuator in protection box

Protection box without slot or predrilled holes

■

Drill two holes into the protection box (from outside to inside) and pull through field wiring cables (CAT 3 fire resistant

cables as BS 8519) to connect to the actuator trailing lead inside the housing, using a standard screwed cable connector

block, the protection box is made of calcium silicate plates.

■

Procedure

■

Use drill (drill size acc. To suit connecting cable Ø + 2 mm for seal up by mastic) and make two holes. It is possible to drill

holes in any side of the housing.

■

Pull the heat resistant cable through the calcium silicate plate (wall) and connect with cables from actuator acc. to

above mentioned electrical diagram.

■

Seal up the space around cable with fire resistant mastic (HILTI CFS-S ACR, PROMASTOP) or equivalent.

■

Let the mastic harden.

Example of position of holes in the wall of the box, without pre-manufactured slot

example drilled

holes