2 - 34

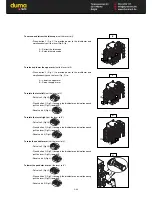

22 - L

OWER ARM RAISING

&

LOWERING AND

TELESCOPE EXTENSION

&

RETRACTION CONTROL

LEVER

- This lever (22) enables you to raise the platform's lower and middle arms

and extend and retract the telescope.

NB

: This lever operates under proportional control enabling precision when

approaching. It must be handled smoothly without sudden jerks.

RAISING THE LOWER ARMS

- Push the lever upwards.

LOWERING THE LOWER ARMS

- Push the lever downwards.

EXTENDING THE TELESCOPE

- Push the lever to the left.

RETRACTING THE TELESCOPE

- Push the lever to the right.

23 - P

LATFORM FORWARD

/

REVERSE MOVEMENT

CONTROL LEVER

- This lever (23) enables you to move the platform.

- You must press trigger A and the dead man’s pedal (41) to make any

movements via the platform’s control box.

- No commands are possible when the pedal or the trigger A is released.

NB

: This lever operates under proportional control enabling precision when

approaching. It must be handled smoothly without sudden jerks.

FORWARD TRAVEL

- Push the lever forwards.

REVERSE TRAVEL

- Push the lever backwards.

STEERING RIGHT

- Press button D.

STEERING LEFT

- Press button G.

When the turret – arm assembly structure rotates more than 90° relative to

the chassis, the travelling controls are reversed. Identify the direction of

movement by looking at the arrows on the chassis and basket control panel.

22

676683 A

67667

4

23

Summary of Contents for 160 ATJ

Page 2: ......

Page 4: ......

Page 6: ......

Page 7: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS 1 OPERATING AND SAFETY INSTRUCTIONS...

Page 8: ......

Page 25: ...1 19 REAR AXLE ASSEMBLY FIG E Axle type Serial Nr Maker s N E...

Page 28: ...1 22...

Page 29: ...2 1 2 DESCRIPTION 2 DESCRIPTION...

Page 30: ......

Page 31: ...2 3...

Page 37: ...2 9...

Page 39: ...2 11...

Page 41: ......

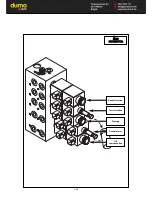

Page 74: ...2 46 MAIN DISTRIBUTOR Basket rotation Turret rotation Steering Pendular arm Tilt compensation...

Page 75: ...3 MAINTENANCE 3 MAINTENANCE...

Page 76: ......

Page 78: ......

Page 105: ...3 31...

Page 107: ...3 33 G3 2 Centre of gravity Platform s total weight 8090 Kg...

Page 111: ...4 ELECTRICITY 4 ELECTRICITY 4 1...

Page 112: ...4 2...

Page 114: ...4 4...

Page 115: ...5 1 5 OPTIONAL ACCESSORIES FOR THE RANGE 5 OPTIONAL ACCESSORIES FOR THE RANGE...

Page 116: ...5 2...

Page 120: ...5 6...

Page 121: ...6 1 6 MAINTENANCE HANDBOOK 6 MAINTENANCE HANDBOOK...

Page 122: ......

Page 130: ......

Page 131: ...Powered by TCPDF www tcpdf org...