DAMPER INSPECTION

1.

Check the shaft for scratches, wear, or other obvious damage.

2.

Check the seal gland and end cap seal grooves for damage.

3.

Check shims for permanent bends or damage.

4.

Check all other parts for obvious damage, replace if necessary.

5.

Replace all seals that have been removed.

FORK INSPECTION

1.

Check the fork boots for obvious damage.

2.

Check the dust seal for tears, wear, or damage. Replace if needed.

3.

Inspect the lower and upper bushing for damage to the Teflon coating. Replace using the bushing removal and replacement kit

if necessary.

4.

Check all MCU & springs for obvious damage. Replace if necessary.

5.

Check the prelude adjuster and connectors. Replace if damaged.

6.

Check the outer leg/arch assembly for nicks or deep gouges on outside and inside. Replace if damaged.

7.

Check the inner leg for deep gouges and other obvious damage. Minor wear resulting in color change is not detrimental to the

gold anodize surface. Replace if wear is excessive or damaged.

8.

Check inner legs at the bottom of the crown for cracks or for flaking anodize. Replace crown steer leg assembly if cracked or if

gold anodize is beginning to flake.

9.

Check the underside of the crown for cracks. Replace if cracked.

RE-ASSEMBLY

Lower Shaft Figure 11:

1.

Install all o-rings and seals removed.

2.

Grease all seals lightly with a seal grease.

3.

Apply small amount of blue loctite to piston seat threads.

4.

Assemble shim stack and spacers inexact order that they were removed. For XVERT & XVERT R , thread on valve nut and

torque 30 IN-LB (3.5 N-m) max. For XVERT TI hand tighten piston seat. Be sure large blow off washer will slide over piston

spacer and compress the small small spring. Clamp shaft in soft jaws or collet and line up slots in clamp ring with hole in

piston seat using 1/8Ó or smaller pin. Use a 5mm allen wrench and tighten piston seat by turning allen wrench and pin at the

same time. Torque 30 IN-LB (3.5N-m) max.

5.

XVERT TI install lower needle gently into shaft, thread until it stops then back off one turn for initial adjustment.

6.

Slide shaft assembly through the plastic end cap, place detent ball in place and slide 2

nd

stg Elastomer.

7.

Insert into left leg and thread in end cap. Torque 30 IN-LB (3.5N-m) max.

8.

Add approximately 100CC of 5WT Maxima or equivalent oil. Do not over fill. Check oil level, see Figure 8.

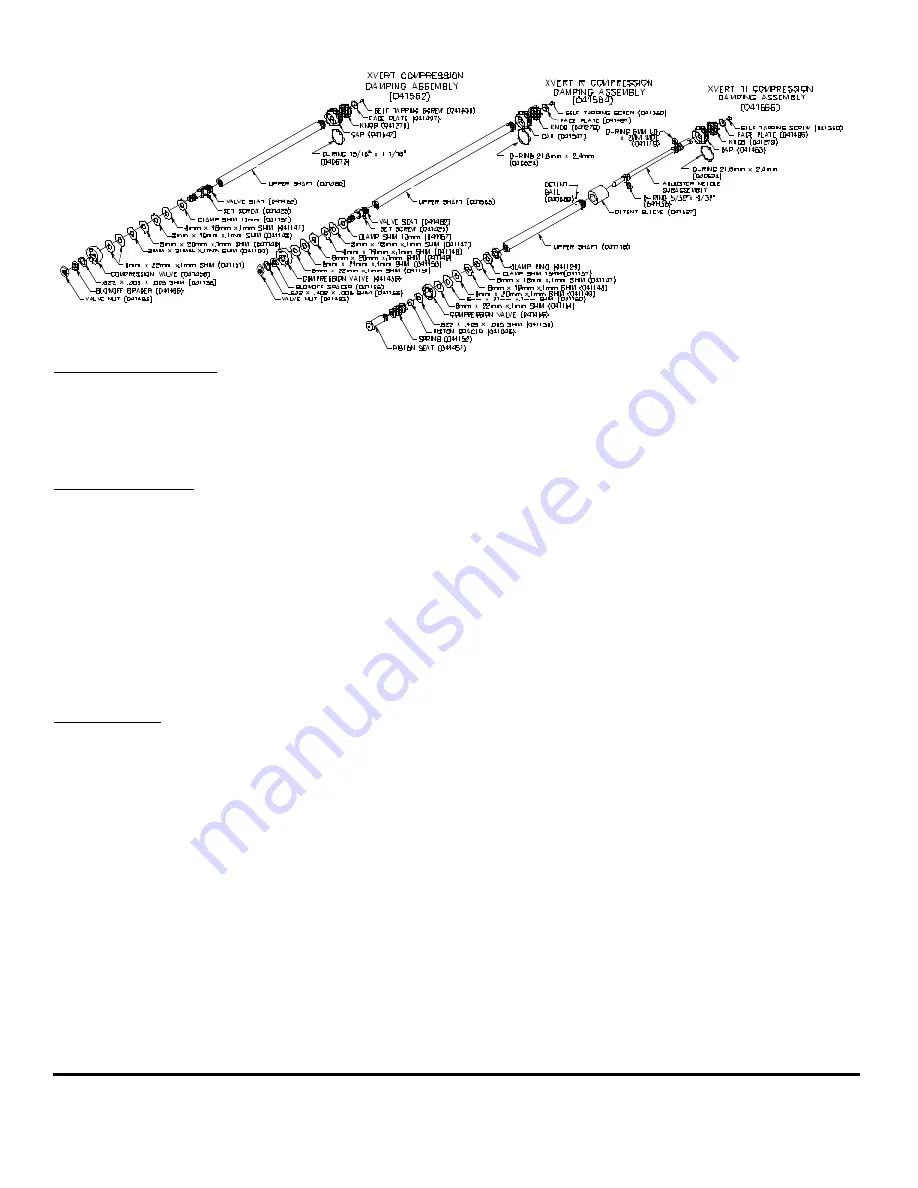

Compression Damping Assembly Figure 12:

1.

Reassemble compression damping stack following the instructions above for the lower shaft assembly.

2.

Install compression damping assembly into the leg. The oil level should cover the compression valve when the assembly is

installed.

Page 9

Compression Rod & Boots Figure 13:

1.

Clean all parts thouroughtly.