3-22

C - EVERY 250 HOURS SERVICE

Carry out the operations described previously as well as the following operations.

C1 - ALTERNATOR BELT TENSION

CHECK - ADJUST

- Pull on the handle located inside the cab to open the engine hood.

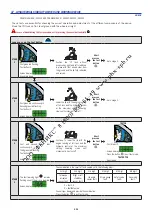

- Unscrew the fastening screws 1 (fig. C1/1).

- Lay down the protective guard 2 (fig. C1/1).

- Check the belt for signs of wear and cracks and change if necessar y (see: 3 - MAINTENANCE:

FILTERS CARTRIDGES AND BELTS).

- Check the belt tension between the pulleys of the crankshaft and of the alternator.

- Under a normal pressure exer ted with the thumb (45 N), the belt should move approximately

10 mm.

- Carr y out adjustments if necessar y.

- Untighten screws 3 (fig. C1/2) with two to three thread turns.

- Swivel the alternator assembly so as to obtain the belt tension required.

- Retighten screws 3 (fig. C1/2) (tightening torque 22 N.m).

- Refit the protective casing.

If the alternator belt has to be changed, check the tension again after the first 20 hours of operation.

C2 - COMPRESSOR BELT TENSION (OPTION AIR CONDITIONING)

CHECK - ADJUST

C3 - ALTERNATOR BELT TENSION (AIR CONDITIONING OPTION)

CHECK - ADJUST

- Pull on the handle located inside the cab to open the engine hood.

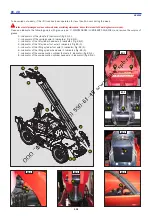

- Unscrew the fastening screws 1 (fig. C2/1).

- Lay down the protective guard 2 (fig. C2/1).

After adjusting the compressor belt, you must carry out the adjustment of the alternator belt.

COMPRESSOR BELT

- Check the belt for signs of wear and cracks and change if necessar y (see: 3 - MAINTENANCE:

FILTERS CARTRIDGES AND BELTS).

- Check the belt tension between the pulleys of the crankshaft and of the compressor.

- Under a normal pressure exer ted with the thumb (45 N), the belt should move approximately

10 mm.

- Carr y out adjustments if necessar y.

- Untighten screws 3 (fig. C2/2) by two to three thread turns.

- Swivel the compressor assembly so as to obtain the belt tension required.

- Retighten screws 3 (fig. C2/2) (tightening torque 22 N.m).

ALTERNATOR BELT

- Check the belt for signs of wear and cracks and change if necessar y (see: 3 - MAINTENANCE:

FILTERS CARTRIDGES AND BELTS).

- Check the belt tension between the pulleys of the alternator and the compressor

- Under a normal pressure exerted with the thumb

(45 N), the belt should move approximately

10 mm.

- Carr y out adjustments if necessar y.

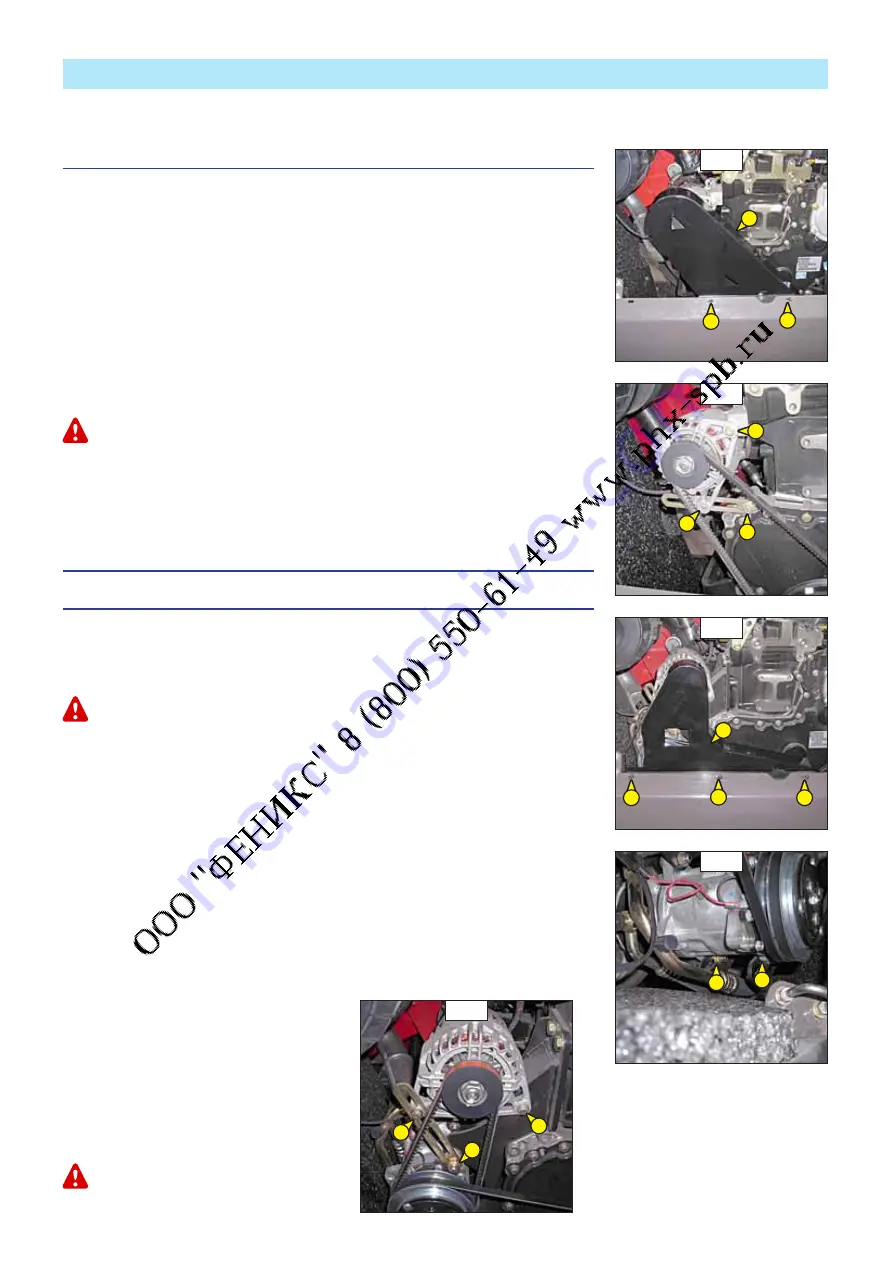

- Untighten screws 4 (fig. C2/3) by two to three

thread turns.

- Swivel the alternator assembly so as to obtain

the belt tension required.

- Retighten screws 4 (fig. C2/3) (tightening

torque 22 N.m).

- Refit the protective casing.

If the compressor belt has to be changed, check the

tension again after the first 20 hours of operation.

C1/1

1

1

2

C1/2

3

3

3

C2/1

1

1

1

2

C2/2

3

3

C2/3

4

4

4

Summary of Contents for MT 1058 R PRIVILEGE

Page 1: ......

Page 3: ......

Page 4: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS...

Page 5: ...1 2...

Page 31: ...1 28...

Page 32: ...2 1 2 DESCRIPTION...

Page 33: ...2 2...

Page 44: ...2 13...

Page 74: ...2 43...

Page 78: ...3 1 3 MAINTENANCE...

Page 79: ...3 2...

Page 84: ...3 7...

Page 92: ...3 15...

Page 104: ...3 27...

Page 116: ...4 1 4 OPTIONAL ATTACHMENTS FOR USE WITH THE RANGE...

Page 117: ...4 2...

Page 119: ...4 4...

Page 129: ...4 14...

Page 130: ...5 1 5 SPECIFIC CANADA...

Page 131: ...5 2...

Page 132: ...5 3 TABLE OF CONTENTS DIMENSIONS AND LOAD CHART MT 1058 R PRIVILEGE 5 4...

Page 135: ...5 6...

Page 136: ...6 1 6 SPECIFIC AUSTRALIA See also the operator s manual supplement 647065 AU...

Page 137: ...6 2...

Page 139: ...6 4...