3 - 8

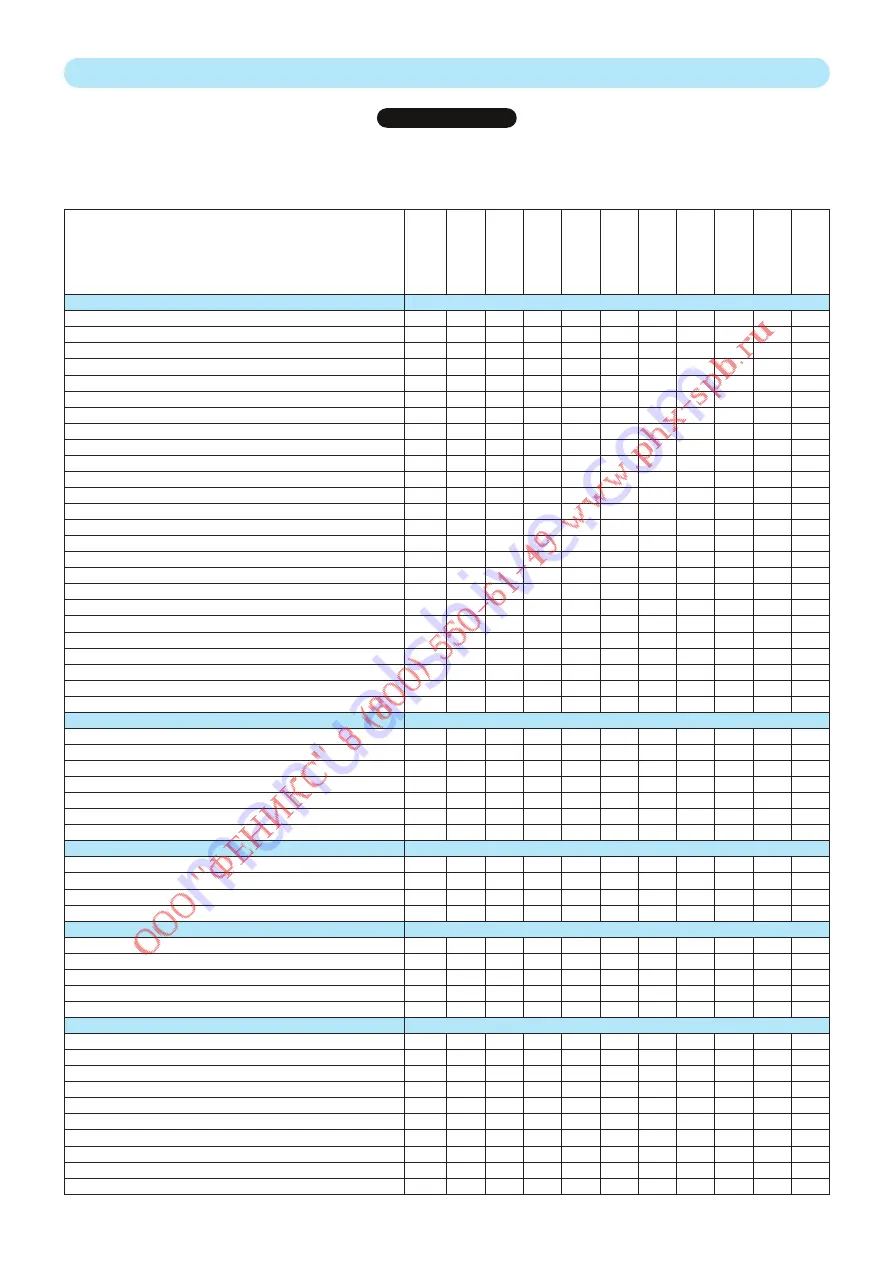

SERVICING SCHEDULE

IMPORTANT

(1): MANDATORY 500 HOUR OR 6 MONTH SERVICE. This service must be carried out after approximately the first 500 hours of operation or within the 6 months following

the start-up of the machine (whichever occurs first).

(2): Every 10 hours during the first 50 hours then a final time at 250 hours.

(3): Contact your dealer.

A = ADJUST, C = CHECK, G = GREASE, N = CLEAN,

P = BLEED, R = REPLACE, V = DRAIN

PAGE

(1)

DAIL

Y OR E

VER

Y 10

HOURS OF SER

VICE

EVER

Y 50 HOURS

OF SER

VICE

EVER

Y 250 HOURS OF SER

VICE

EVER

Y 500 HOURS OF SER

VICE

OR E

VER

Y Y

EAR

EVER

Y 1000 HOURS

OF SER

VICE OR

EVER

Y T

W

O Y

EARS

EVER

Y 2000 HOURS

OF SER

VICE OR

EVER

Y T

W

O Y

EARS

EVER

Y 3000 HOURS OF SER

VICE

EVER

Y 4000 HOURS OF SER

VICE

OC

CASIONALL

Y

ENGINE

-Engine oil level

3-10

C

-Cooling liquid level

3-10

C

C

-Fuel level

3-10

C

C

-Fuel pre-filter

3-11

C

-Radiator core

3-14

N

N

-Compressor belt tension (Air conditioning OPTION)

3-20

C/A

C/A

-Engine oil

3-22

V

V

-Engine oil filter

3-22

R

R

-Fuel pre-filter cartridge

3-23

R

R

-Fuel filter cartridge

3-23

R

R

-Dry air filter cartridge

3-26

R

-Engine crankcase ventilation filter

3-26

R

-Fuel tank

3-27

N

-Engine silent blocks

C (3)

-Engine rates

C (3)

-Valves clearances

C

C (3)

-Cooling liquid

3-30

V

-Radiator

C (3)

-Water pump and the thermostat

C (3)

-Alternator and the starter motor

C (3)

-Turbocompressor

C (3)

-Safety dry air filter cartridge

3-34

R

-Alternator belt

3-34

R

-Fuel circuit

3-36

P

-"Stationary lift truck" exhaust particle filter

3-36/37

XXX

TRANSMISSION

-Gear box oil level

3-14

C

-Gear box oil

3-27

V

V

-Gear box oil filter

3-27

R

R

-Silentblocks in the gear box

C (3)

-Gear box controls

C (3)

-Transmission pressures

C (3)

-Wear of the brake pads and the brake disk

C (3)

TYRES

-Tyre pressures

3-15

C

C

-Wheel nut torques

3-15

C

C

-Wheel nut tightening torque

3-30

C

C

-Wheel

3-37

R

BOOM

-Boom pads

3-11

G (2)

-Boom

3-16/17

G

G

-Boom pad wear

C (3)

-Condition of boom unit

C

C (3)

-Bearings and articulation rings

C (3)

HYDRAULICS

-Hydraulic oil level

3-18

C

C

-Hydraulic oil

3-24/31

C

V

-Hydraulic return oil filter cartridge

3-28

R

-Breather for the hydraulic oil tank

3-30/31

R

-Suction strainer for hydraulic oil tank

3-30/31

N

-Brake accumulator unit filter

3-30/31

R

-Hydraulic pump tubular filter

N (3)

-Condition of hoses and flexible pipes

C (3)

-Condition of cylinders (leakage, shafts)

C (3)

-Hydraulic circuit pressures

C (3)

647104

(13/06/2016)

MT

835

/ 1135

/ 1335

ST3B

Summary of Contents for MT 1135 ST3B

Page 4: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 5: ...1 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 6: ...1 3 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 31: ...1 28 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 32: ...2 1 2 DESCRIPTION 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 33: ...2 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 50: ...2 19 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 96: ...2 65 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 103: ...2 72 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 104: ...3 1 3 MAINTENANCE 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 105: ...3 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 116: ...3 13 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 128: ...3 25 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 136: ...3 33 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 138: ...3 35 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 145: ...3 42 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 146: ...4 1 4 OPTIONAL ATTACHMENTS FOR USE WITH THE RANGE 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 147: ...4 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 149: ...4 4 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 158: ...4 13 647104 13 06 2016 MT 835 1135 1335 ST3B...