3 - 26

E - EVERY 1000 HOURS OF SERVICE OR EVERY TWO YEARS

Carry out the operations described previously as well as the following operations.

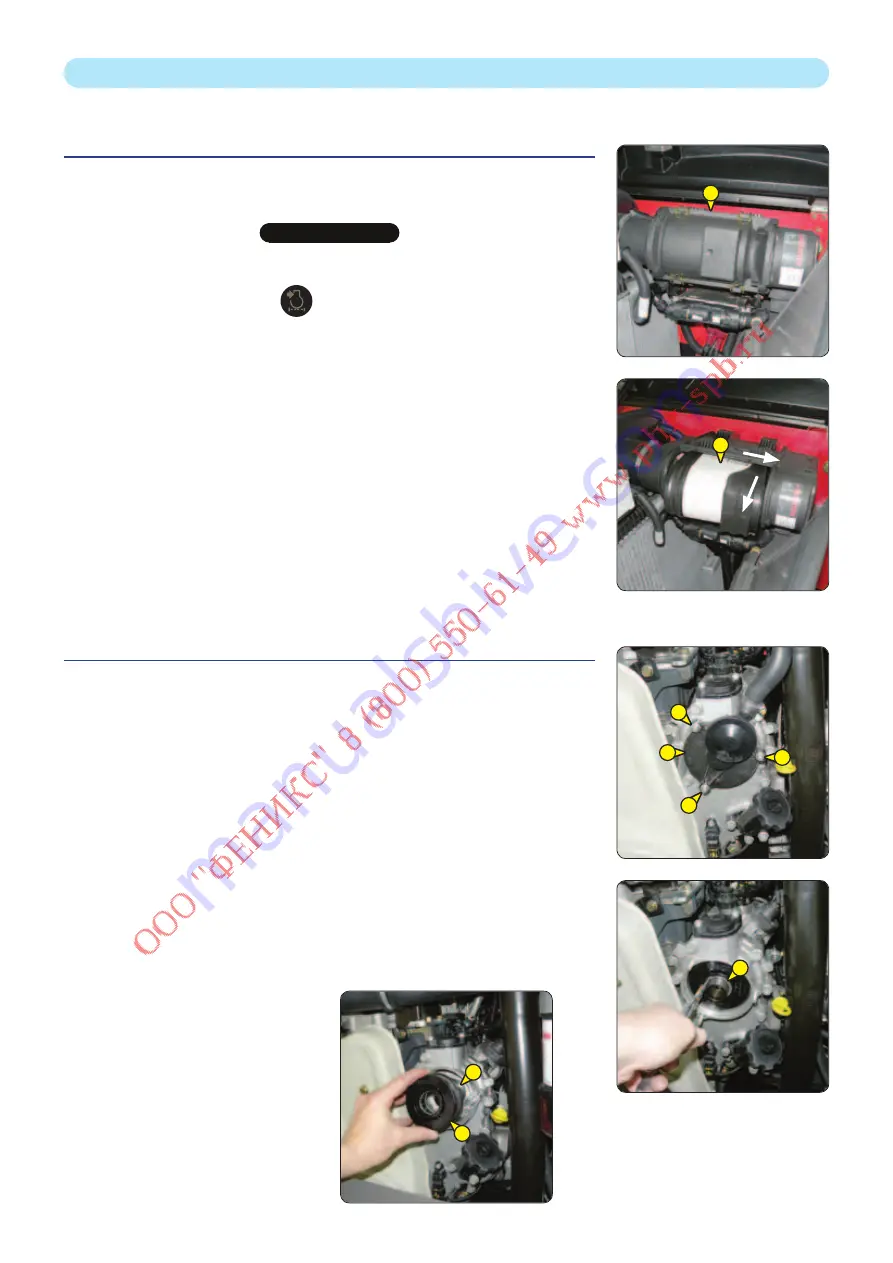

E1 – DRY AIR FILTER CARTRIDGE

CHANGE

In case of use in a heavily dust laden atmosphere, the cartridge replacement interval

must be reduced (to 250 hours in a heavily dust laden atmosphere).

IMPORTANT

Change the cartridge in a clean location, with the engine stopped.

Never operate the lift truck with the air filter removed or damaged.

If the air filter clogging indicator light comes on

, replace the cartridge with minimum delay (maximum 1 hour).

- Open the engine bonnet.

- Loosen the bolts and remove cover 1.

- Pivot cartridge 2 towards the front and carefully remove to avoid spilling the dust.

- Leave the safety cartridge in place.

- The following parts must be cleaned with a damp, clean lint-free cloth.

• The inside of the filter and cover.

• The inside of the filter inlet hose.

• The gasket surfaces in the filter and in the cover.

- Check pipes and connections between the air filter and the engine and the connection

and state of the clogging indicator on the filter.

- Before mounting, check the state of the new filter cartridge (see: 3 - MAINTENANCE:

FILTERS, CARTRIDGES AND BELTS).

- Tilt the cartridge approximately 5° towards the front, insert it into the filter and

position it by pressing the edges and not the middle.

- Refit the cover and ensure that the clips are properly secured. The cover should fit

on easily, if this is not the case, check the position of the cartridges in the filter.

E2 – ENGINE CRANKCASE VENTILATION FILTER

CHANGE

- Open the engine bonnet.

- Carefully clean the outside of the filter and its holder, to prevent dust from getting

into the system.

- Undo the nuts 1 and remove the cover 2.

- Remove the circlips 3, extract the filter 4 and discard it together with the seal of

the cover 2.

- Refit a new seal on the cover and insert a new filter (see: 3 - MAINTENANCE: FILTERS

CARTRIDGES AND BELTS).

NOTE: Ensure that the flats of the filter 4 and shaft 5 are aligned.

- Put back the circlips 3, refit the cover 2 and tighten the nuts 1 (tightening torque

25 N.m).

1

1

1

2

3

4

5

1

2

647104

(13/06/2016)

MT

835

/ 1135

/ 1335

ST3B

Summary of Contents for MT 1135 ST3B

Page 4: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 5: ...1 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 6: ...1 3 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 31: ...1 28 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 32: ...2 1 2 DESCRIPTION 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 33: ...2 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 50: ...2 19 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 96: ...2 65 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 103: ...2 72 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 104: ...3 1 3 MAINTENANCE 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 105: ...3 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 116: ...3 13 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 128: ...3 25 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 136: ...3 33 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 138: ...3 35 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 145: ...3 42 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 146: ...4 1 4 OPTIONAL ATTACHMENTS FOR USE WITH THE RANGE 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 147: ...4 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 149: ...4 4 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 158: ...4 13 647104 13 06 2016 MT 835 1135 1335 ST3B...