1 - 15

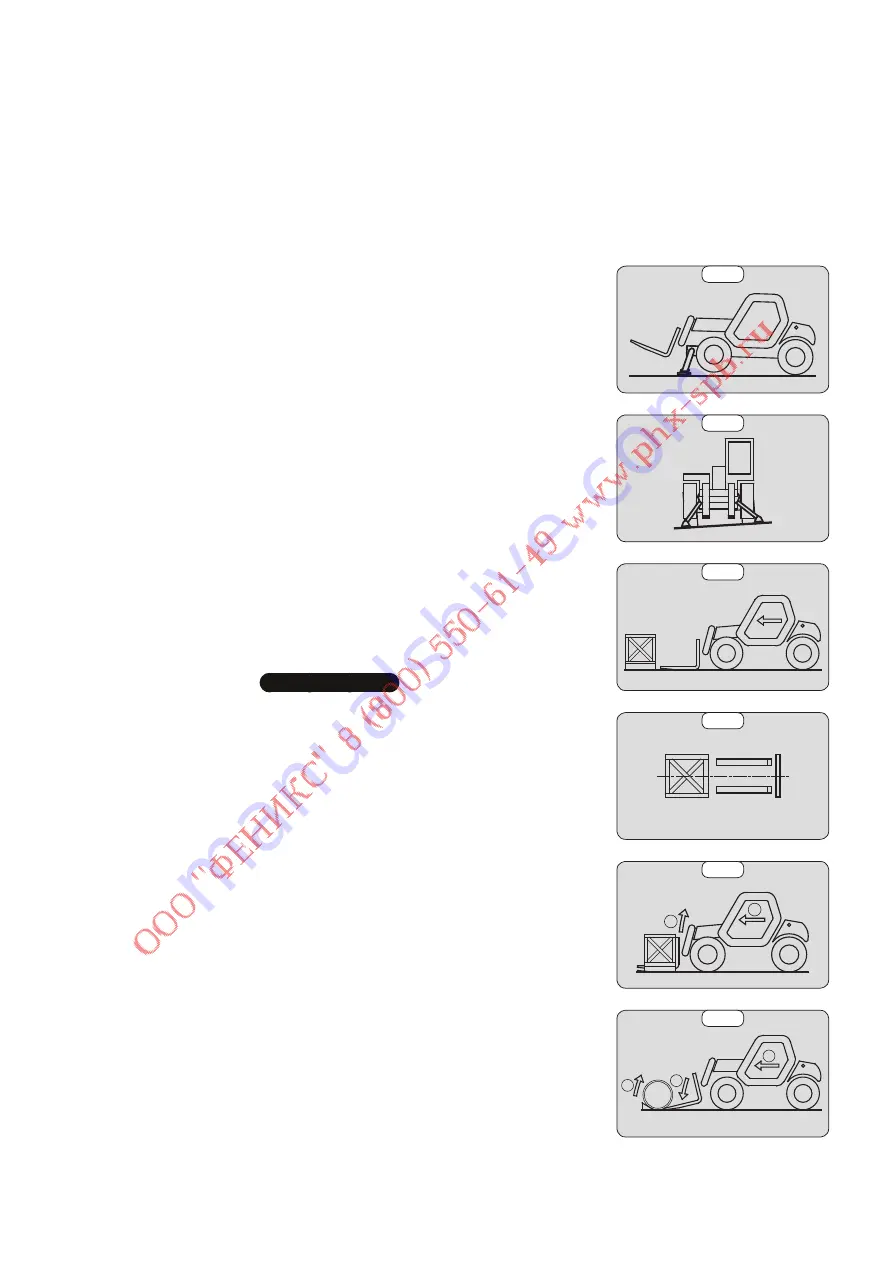

D - TRANSVERSE ATTITUDE OF THE LIFT TRUCK

Depending on the model of lift truck

The transverse attitude is the transverse slope of the chassis with respect to the horizontal.

Raising the jib reduces the lift truck's lateral stability. The transverse attitude must be set with the jib in down position as follows:

1 - LIFT TRUCK WITHOUT ROLL CORRECTOR USED ON TYRES

- Position the lift truck so that the bubble in the level is between the two lines (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

2 - LIFT TRUCK WITH ROLL CORRECTOR USED ON TYRES

- Correct the roll using the hydraulic control and check horizontality with the spirit level. The bubble in the level must

be between the two lines (see: 2 - DESCRIPTION: INSTRUMENTS AND CONTROLS).

3 - LIFT TRUCK USED ON STABILIZERS

- Set the two stabilizers on the ground and raise the two front wheels of the lift

truck (fig. D1).

- Correct the roll using the stabilizers (fig. D2) and check horizontality with the spirit

level. The bubble of the level must be between the two lines (see: 2 - DESCRIPTION:

INSTRUMENTS AND CONTROLS). In this position, the two front wheels must be off

the ground.

E - TAKING UP A LOAD ON THE GROUND

- Approach the lift truck perpendicular to the load, with the jib retracted and the

forks in a horizontal position (fig. E1).

- Adjust the fork spread and centring relative to the load to ensure stability (fig. E2)

(optional solutions exist, consult your dealer).

- Never lift a load with a single fork.

IMPORTANT

Beware of the risks of trapping or squashing limbs when manually adjusting the forks.

- Move the lift truck forward slowly (1) and insert the forks under the load as far as

they will go (fig. E3). If necessary, slightly lift the jib (2) while taking up the load.

- Bring the load into the transport position.

- Tilt the load far enough backwards to ensure stability (loss of load on braking or

going downhill).

FOR A NON-PALLETISED LOAD

- Tilt the carriage (1) forwards and move the lift truck slowly forwards (2), to insert

the fork under the load (fig. E4) (block the load if necessary).

- Continue to move the lift truck forwards (2) tilting the carriage (3) (fig. E4) backwards

to position the load on the forks and check the load's longitudinal and lateral stability.

E1

E2

1

2

E3

1

2

3

E4

D2

D1

647104

(13/06/2016)

MT

835

/ 1135

/ 1335

ST3B

Summary of Contents for MT 1135 ST3B

Page 4: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 5: ...1 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 6: ...1 3 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 31: ...1 28 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 32: ...2 1 2 DESCRIPTION 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 33: ...2 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 50: ...2 19 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 96: ...2 65 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 103: ...2 72 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 104: ...3 1 3 MAINTENANCE 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 105: ...3 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 116: ...3 13 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 128: ...3 25 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 136: ...3 33 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 138: ...3 35 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 145: ...3 42 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 146: ...4 1 4 OPTIONAL ATTACHMENTS FOR USE WITH THE RANGE 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 147: ...4 2 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 149: ...4 4 647104 13 06 2016 MT 835 1135 1335 ST3B...

Page 158: ...4 13 647104 13 06 2016 MT 835 1135 1335 ST3B...