3-37

G8 - LONGITUDINAL STABILITY LIMITER AND WARNING DEVICE

RESET

According to the use of the lift truck, the device may require to be periodically reset.

This operation can be easily performed by means of the following procedure.

- Provide a fork carrier or a bucket and a load corresponding to at least half the lift truck’s rated capacity.

- Preferably perform the reset when the lift truck is still cold (before it is used) or ensure that the temperature of the rear axle is not more

than 50°C.

- Place the lift truck on flat, level ground with the wheels straight.

Scrupulously follow the jib positioning instructions. Should you fail to follow these instructions, two audible beeps will be sounded and the fault

indicator lamp

will come on. If in doubt, consult your dealer.

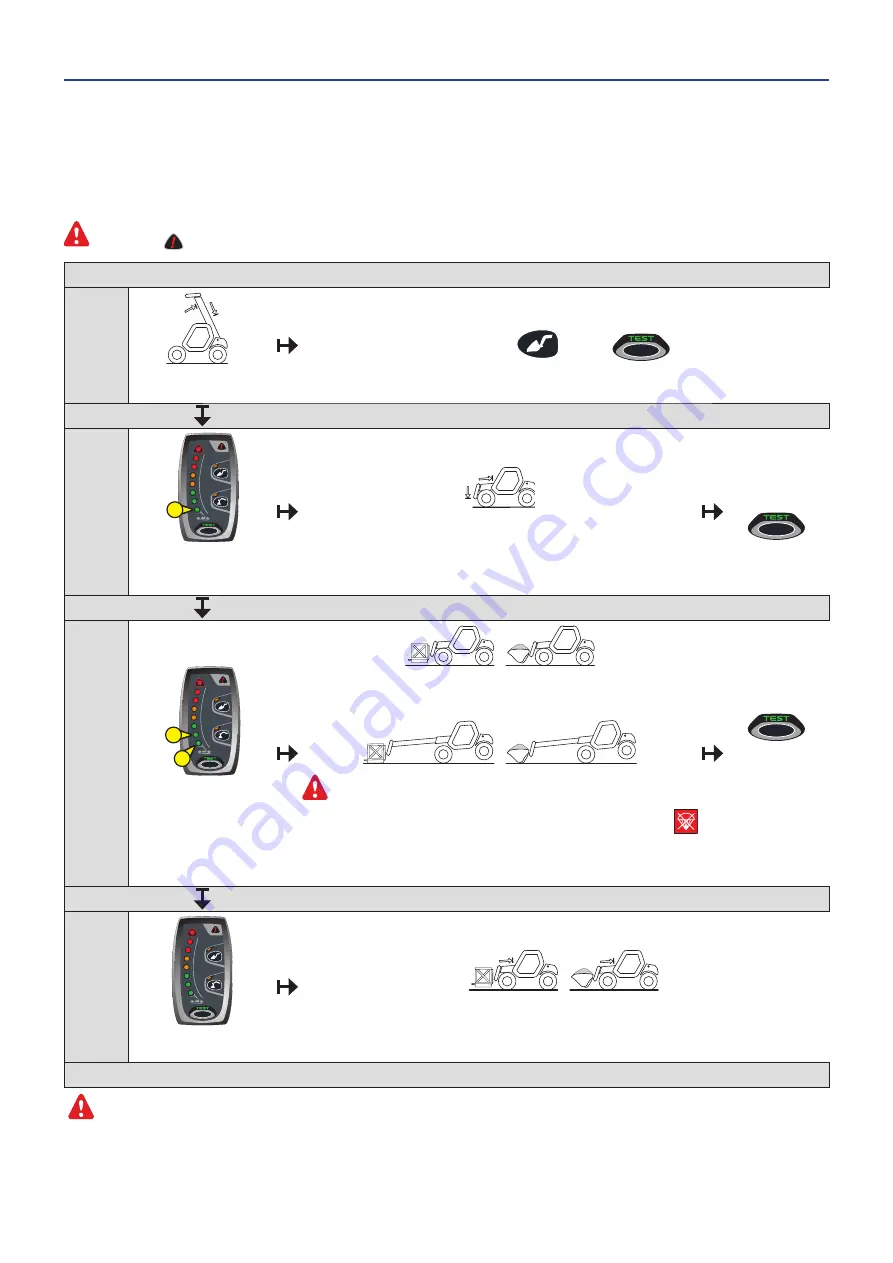

STAGE 1

START

- Without attachments.

- Jib fully retracted and raised.

Simultaneously press and hold down

the “BUCKET” MODE

and TEST

buttons.

- Two audible beeps will be sounded and all the LEDs will flash twice to confirm the start of the procedure.

STAGE 2

1

- An audible beep.

- First green led flashing.

- Flashing test button.

- Without attachments.

- Carriage tilted fully backward.

- Jib fully retracted and in the down position a few centimetres off the ground.

Short press the test

button.

STAGE 3

2

1

- First green led continuously

lit.

- Second green led flashing.

- Flashing test button.

/

- With the fork carrier or the bucket and a load (keep jib retracted to allow all other

hydraulic movements).

- Jib fully retracted and in the down position a few centimetres off the ground.

/

Keep the load as close to the ground as possible throughout this operation.

- Hold down the disable the “aggravating” hydraulic movement cut-off button

(indicator lamp lit), and telescope the jib until the rear wheels are off the ground.

NOTA: This stage consists in unloading the rear axle. It can be done using a jack

but without bearing on the rear axle.

Short press the test

button.

-

Two audible beeps

will be sounded and

all the LEDs will flash

twice to confirm the

end of the procedure.

STAGE 4

FINISH

- All LEDs lit.

- A continuous audible beep.

/

- After completing the resetting procedure, the lift truck is in an overloaded condition. Retract the telescope to restore the

situation.

When the reset is completed, check the operation of the longitudinal stability limiter and warning device (see: 3 - MAINTENANCE: A - DAILY OF EVERY 10 HOURS

SERVICE).

647421

(22/08/2017)

MT-X

625

Série

2-E3

+

COMFORT

Summary of Contents for MT-X 625 2-E3 Series

Page 5: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 6: ...1 2 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 32: ...1 28 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 33: ...2 1 2 DESCRIPTION 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 34: ...2 2 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 45: ...2 13 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 69: ...2 37 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 71: ...2 39 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 77: ...3 1 3 MAINTENANCE 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 78: ...3 2 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 83: ...3 7 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 91: ...3 15 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 107: ...3 31 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 112: ...3 36 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 114: ...3 38 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 116: ...4 2 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 118: ...4 4 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 130: ...5 2 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...

Page 132: ...5 4 647421 22 08 2017 MT X 625 S rie 2 E3 COMFORT...