50960025/CP0514

48

PRINTED IN U.S.A.

2.

Rigging should comply with OSHA regulation

§1910.184, “Slings,” or §1926.251, “Rigging

equipment for material handling.”

3.

Be sure the rigging equipment is clear of any part

of the machine or machine attachment before lift-

ing the load.

4.

Avoid lifting double-tiered or any unstable loads.

5.

Only lift loads vertically and clear from any adja-

cent obstacles. Never drag the load horizontally.

6.

Use multiple lift points and taglines to restrain the

load from swinging or rotating.

Carrying Suspended Load

1.

Rigging between the load and attachment should

be as short as possible to reduce boom height.

2.

Do not raise the load more than 12 inches (305

mm) above the ground or raise the boom more

than 45 degrees.

3.

All telehandler movements should be performed

slowly and cautiously to prevent load swing.

Avoid abrupt movement. Do not exceed walking

speed.

4.

Use a signal person anytime the load restricts the

operators view or assistance is required. The sig-

nal person should remain in contact (verbally or

visually) with the operator at all times until the

load is placed.

Ground Level Suspended Load Placement

1.

Be sure the area under the load and around the

telehandler is clear of equipment and personnel.

2.

Lower the load to the ground till load is stationary

and the rigging is loose from the load. Have sig-

nal person disconnect the rigging from the load.

3.

Raise boom enough to clear the rigging from the

load before backing the telehandler away from the

load.

Elevated Suspended Load Placement

1.

Bring the telehandler as close as possible to the

landing point.

2.

Level the telehandler BEFORE raising the load.

Use extreme caution for high placement. Be sure

personnel are clear of the load landing area.

3.

Set the parking brake, shift the transmission into

neutral, hold the service brake pedal fully applied

and slowly raise the load.

4.

As the load approaches the landing point, feather

the boom control at minimum speed until the load

is just above the landing point.

5.

With the assistance of a signal person, continue

the feathering technique to lower the load into

place.

6.

Once the load is stationary on the landing point

and the rigging is loose from the load, have the

signal person disconnect the rigging from the

load.

7.

Raise boom enough to clear the rigging from the

load. Slowly and carefully, reverse the telehandler

till the rigging is clear of the load.

8.

Lower the boom to travel height.

Installation of a Personnel Work Platform

(PWP)

1.

Center the forks on the carriage, spaced apart to

match the distance required to engage the PWP.

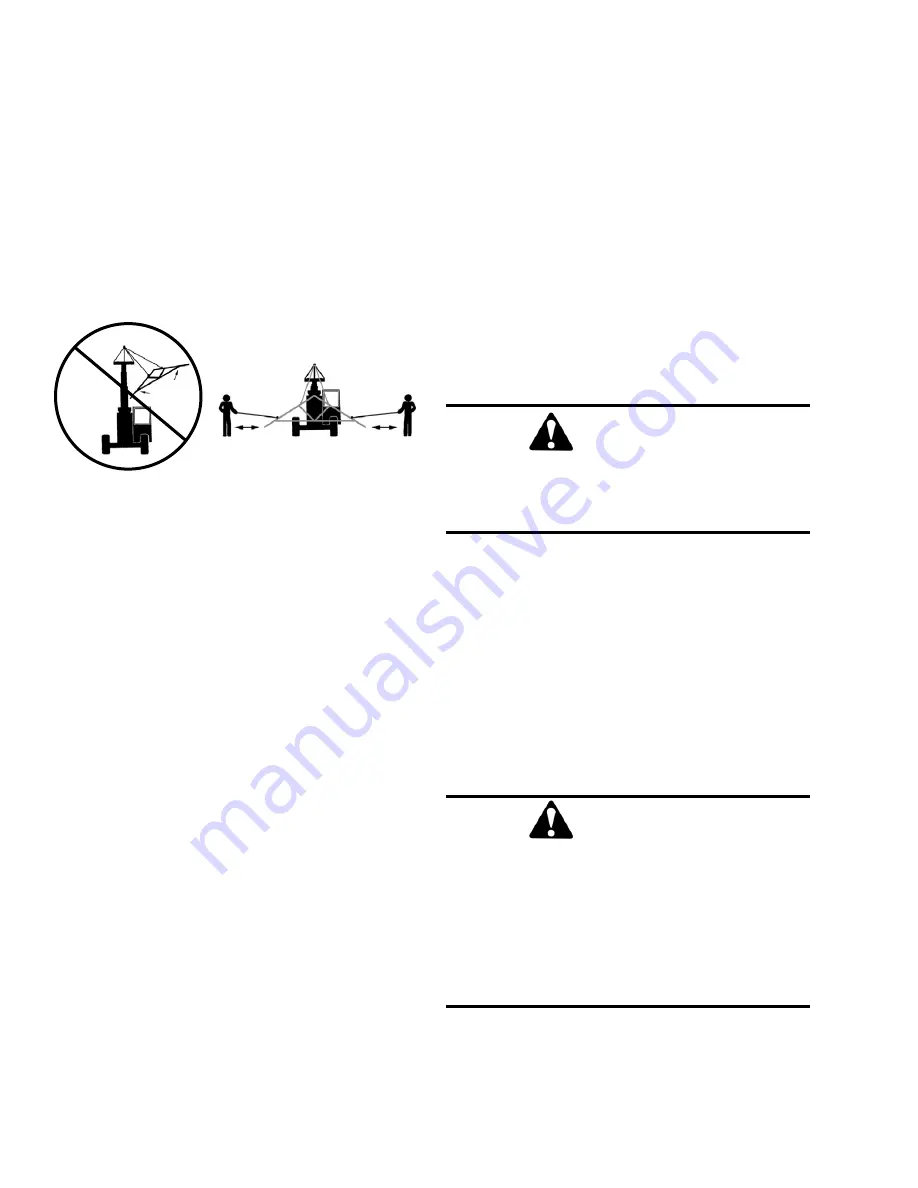

WARNING

NEVER place the signal person between the

load and the telehandler or other stationary

objects.

WARNING

The machine must not be used to lift or carry

personnel, or be fitted with any form of per-

sonnel work platform unless fitted with the

optional PWP System.

If fitted with the PWP System, the Mandatory

Work Platform Safety Rules (p. 15) must be

adhered to at all times while lifting personnel.