MAINTENANCE

120

Printed in U.S.A.

1 .

With the machine running and the drive

system not moving, remove tension cyl-

inder stop (K, Fig . 76) on the side on the

machine with the track to be replaced .

Fig. 77 -

P

Track Tension Switch

2 .

With the machine running and the drive

system not moving, open the engine

compartment . Press and hold the red lock

button (P, Fig . 77) on the track tension

service switch, press the switch to set the

track tension cylinders into the service

(retracted) position .

3 .

When the track tension cylinders are in

the service (retracted) position, shut off

the machine .

4 .

Raise the machine about 150 mm (6 .0”)

so the tracks are free to move .

Use solid support blocking. Never rely

on jacks or other inadequate supports

when maintenance work is being done.

Never work under any equipment sup-

ported only by jacks.

5 .

Use a pry bar to pry/guide the old track at

off the front idler wheel.

6 .

Using a hoist with a hook installed and a

pry bar, lift/guide the old track off at the

drive sprocket . Remove the old track .

7 . Using a hoist with a hook, lift the new

track and maneuver the track under the

50950436

/

H0521

rear idler wheel at using a pry bar and

your foot .

IMPORTANT:

Guides on the inside of

the track must straddle the rear idler.

8 .

Place a block under the new track to hold

the track against the bottom of the rear

idler wheel .

9 .

Using a hoist with a hook and a pry bar,

lift/ guide the new track onto the drive

sprocket .

IMPORTANT:

Lugs on the inside of

the track must be fully engaged by drive

sprocket.

Using a pry bar and wedging blocks, pull/

guide the new track over the front idler wheel

and under the bottom rollers . Carefully, direct

an assistant to start the machine and direct

the assistant to operate the track drive slowly

forward/back to work the track over the front

idler wheel .

Keeps hands and feet clear from

between the track and the idler/

roller wheels when installing tracks.

Crushing of body parts and amputation

can result.

NOTE:

The tie-down bracket can be

used as a lever point for prying the track

into place over the front idler wheel.

IMPORTANT:

Guides on the inside of

the track must straddle the front idler and

bottom roller wheels.

10 . Be sure the new track is fully engaged

around the idler and roller wheels, and in

the drive sprocket, all the way around .

11 . Remove any wedging blocks that were

used to guide the track .

12 . Remove the block placed under the track .

Summary of Contents for MUSTANG 1050RT

Page 63: ...Indicators and Controls 50950436 H0521 60 Printed in U S A ...

Page 109: ...50950436 H0521 106 Printed in U S A ...

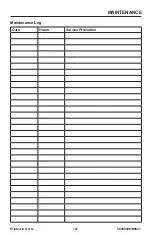

Page 127: ...MAINTENANCE 50950436 H0521 124 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Page 128: ...MAINTENANCE Printed in U S A 125 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Page 129: ...MAINTENANCE 50950436 H0521 126 Printed in U S A Maintenance Log Date Hours Service Procedure ...

Page 130: ...MAINTENANCE Printed in U S A 127 50950436 H0521 Maintenance Log Date Hours Service Procedure ...

Page 131: ...MAINTENANCE 50950436 H0521 128 Printed in U S A ...

Page 142: ...Troubleshooting Printed in U S A 139 50950436 H0521 Error Codes ...

Page 143: ...Troubleshooting 50950436 H0521 140 Printed in U S A ...

Page 144: ...Troubleshooting Printed in U S A 141 50950436 H0521 ...

Page 145: ...Troubleshooting 50950436 H0521 142 Printed in U S A ...

Page 146: ...Troubleshooting Printed in U S A 143 50950436 H0521 ...