WARNING

Line voltage is present inside control. Contact

with line voltage can cause serious injury or

death.

Differential, Anti-Short Cycle Delay,

Temperature Offset, or Sensor Failure Operation

To set or verify the Differential, Anti-Short Cycle

Delay, Temperature Offset or Sensor Failure Operation

use the following method:

Factory preset temperature control code settings, as

follows:

A.

Press and hold MENU until the display

changes to flashing SP.

B.

Press up and down (arrows) repeatedly until

the desired function is displayed.

C.

Press MENU to display the function’s current

value.

D.

Press up and down (arrows) until the desired

value is displayed.

E.

Press MENU to save the new value. The

display returns to the sensor temperature.

F.

If no setup entry is made for 30 seconds, the

control reverts to the temperature display.

Any saved control settings are non-volatile and remain

in the control’s memory during power interruptions.

Check Procedure

If the control system does not function properly, verify

that the control is wired and set up properly. If the

problem persists, use the following procedures to

determine the cause of the problem

IMPORTANT:

Follow these troubleshooting procedures in the order

presented. Do not skip any of the steps in the

procedures.

1.

Check for proper voltage to the control.

A.

Remove the cover by loosening the four cover

screws.

B.

Use an AC voltmeter to check the voltage

between the common and 120V or 240V

terminals.

C.

The voltage must be between 102 and 132

volts for 120V applications; 177 and 264 volts

for 208/230V applications.

D.

If the voltage reading is not within the required

range, check the power source and input power

wires for problems.

2.

Fault Codes

If the LCD displays an alarm or fault code (SF or EE):

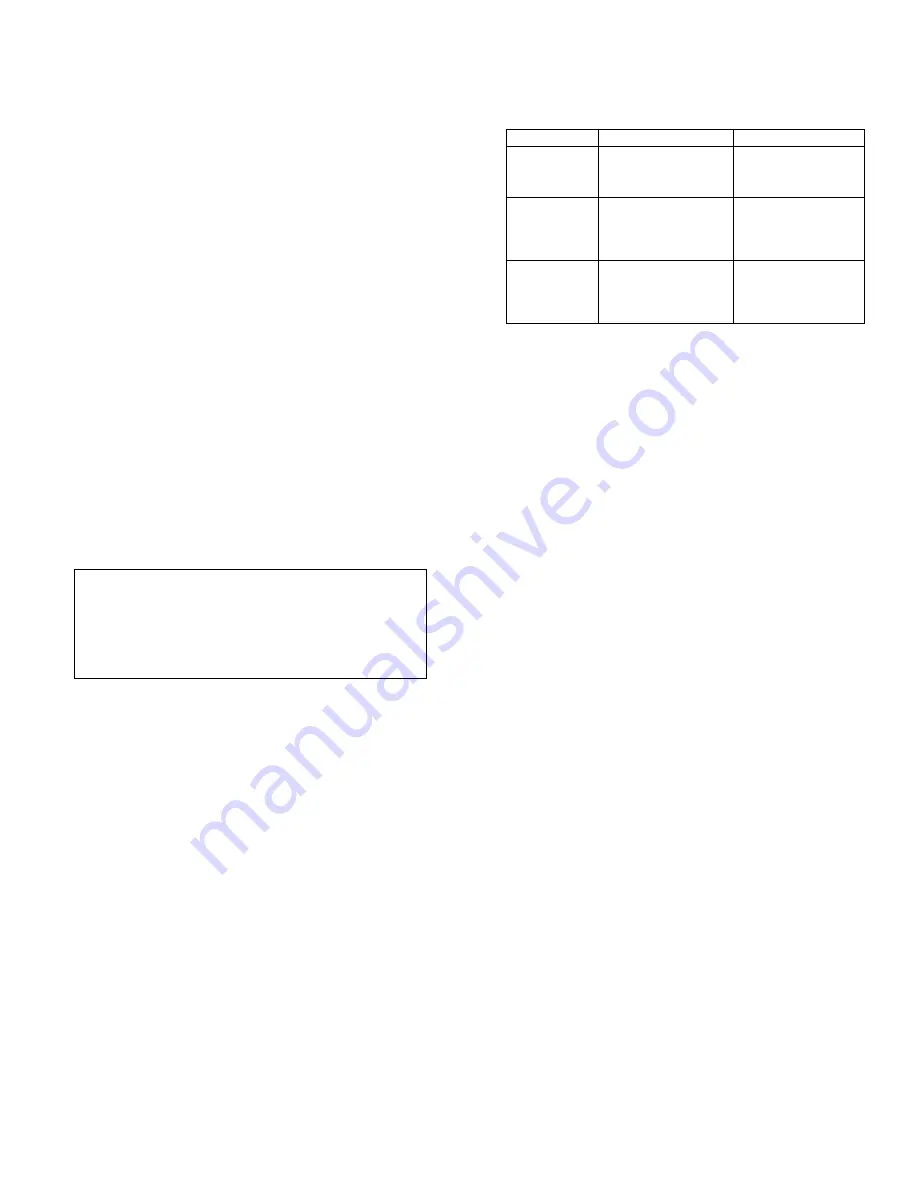

Fault Code

Definition

Solution

SF flashing

alternately with

OP

Open temperature

sensor or sensor wiring

See Step 3. Cycle

power to reset control.

SF flashing

alternately with

SH

Shorted temperature

sensor or sensor wiring

See Step 3. Cycle

power to reset control

EE

Program failure

Reset the control by

pressing MENU. If

problem persists,

replace the control.

3.

Check for proper operation.

IMPORTANT:

Perform Steps 1 and 2 before performing these steps:

A.

Disconnect the load from the output relay

terminals.

B.

Reconnect the sensor leads and supply power

to the control.

C.

Replace the cover.

D.

Check the control settings for proper values.

E.

Press and hold MENU until SP appears.

F.

Press up and down (arrows) to change the set

point temperature above and below the sensor

temperature until the relay energizes and de-

energizes.

G.

If the output relay does not perform as

indicated, replace the control.

H.

If proper operation of the control is verified,

reconnect the load.