22

Part Number 000012545 Rev 02 11/16

Operation

Section 3

Operational Checks

GENERAL

All ice machines are factory-operated and adjusted before

shipment. Normally, new installations do not require any

adjustment.

To ensure proper operation, always follow the Operational

Checks:

• when starting the ice machine for the first time

• after a prolonged out-of-service period

• after cleaning and sanitizing

NOTE: Routine adjustments and maintenance procedures

are not covered by the warranty.

MINIMUM/MAXIMUM SLAB WEIGHTS

Adjust ice thickness to meet chart specifications.

Model

Minimum Ice Weight

Per Cycle

Maximum Ice Weight

Per Cycle

K0250

3.4 lbs

1542 g

3.9 lbs

1769 g

K0350

3.4 lbs

1542 g

3.9 lbs

1769 g

K420

3.4 lbs

1542 g

3.9 lbs

1769 g

K0500

4.125 lbs

1871 g

4.75 lbs

2154 g

K0600

4.125 lbs

1871 g

4.75 lbs

2154 g

K1000

7.25 lbs

3288 g

7.75 lbs

3515 g

K1350

12.8 lbs

5805 g

14.4 lbs

6532 g

K1800

12.8 lbs

5805 g

14.4 lbs

6532 g

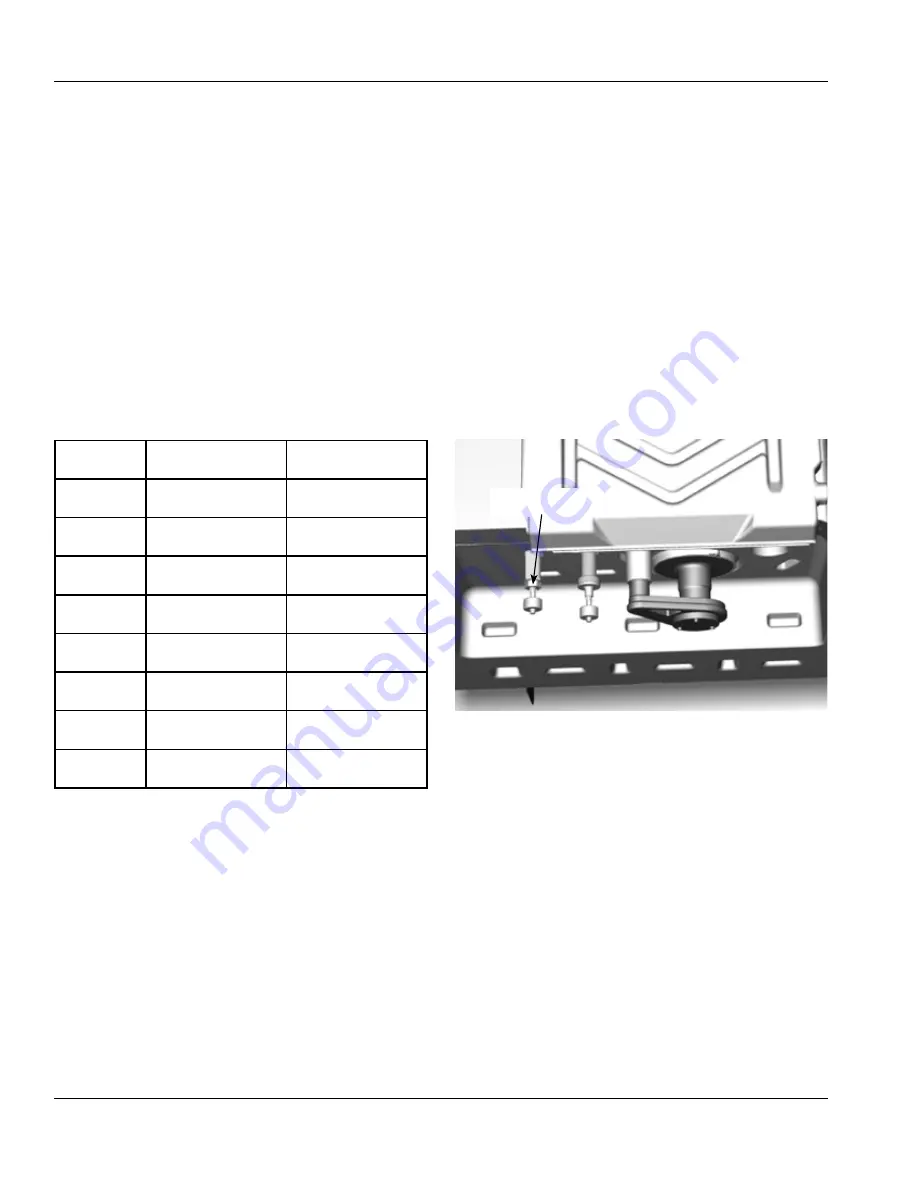

ICE THICKNESS CHECK

After a harvest cycle, inspect the ice cubes in the ice storage

bin. The ice thickness float switch is factory-set to maintain

the ice bridge thickness at 1/8" (3 mm).

NOTE: Make sure the water curtain is in place when

performing this check. It prevents water from splashing out

of the water trough.

1. Inspect the bridge connecting the cubes. It should be

about 1/8" (3 mm) thick.

2. If adjustment is necessary, turn the ice thickness

float switch clockwise to increase bridge thickness,

counterclockwise to decrease bridge thickness. Adjust

to achieve a 1/8" (3 mm) bridge thickness.

NOTE: The float can be adjusted with a 3/4" wrench while

the water trough is in place. Test run two cycles to verify

water level.

Ice Thickness Float

Switch Adjustment