Part Number: 040005890 Rev 04 02/19

19

Section 4

Maintenance

REMOVE PARTS FOR CLEANING

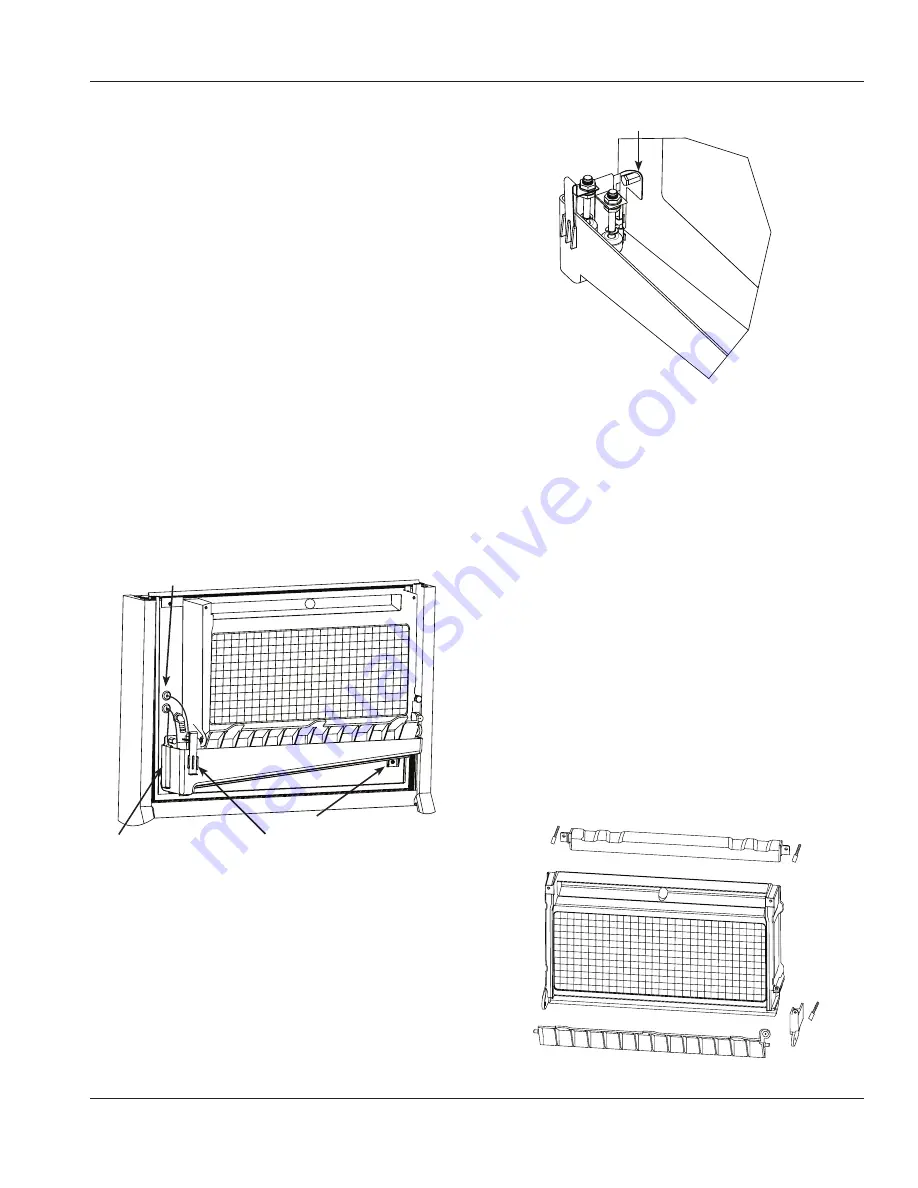

A. Remove the ice thickness and harvest float switch.

Pull forward on the bottom of the bracket until clear of the

tab, then slide bracket upward to remove the bracket and

float switch as an assembly.

NOTE: At this point, the component can easily be cleaned.

If complete removal is desired, follow the wires to the

bulkhead grommet (exit point) in the back wall. Pull the

wire connector through the bulkhead grommet, then

disconnect the wire leads from the connector.

Important

Reversing the mounting location of the ice thickness and

the harvest floats will result in a safety limit 2 failure.

• The ice thickness float must be mounted to the front of

the water trough and the electrical connection must be

in the top bulkhead grommet.

• The harvest float must be mounted to the side of the

water trough and the electrical connection must be in

the bottom bulkhead grommet.

• The wire connectors for each float are different and will

not allow incorrect electrical bulkhead connection.

Wire Connectors Are Located Behind Bulkhead,

Pull Through Grommet To Disconnect

Harvest Float Switch & Bracket

Ice Thickness Float Switch & Bracket

Lower Thumbscrew

Thumbscrew & Thermistor Bracket

B. Remove water trough thermistor and water trough.

• While supporting the water trough, remove the upper

thumbscrew and lift off the thermistor.

• Continue supporting the water trough and remove the

thumbscrew from beneath the water trough.

• Remove the water trough from the bin area.

NOTE: At this point, the thermistor can easily be cleaned.

If complete removal is desired, follow the wires to the

bulkhead grommet (exit point) in the back wall. Pull the

wire connector through the bulkhead grommet, then

disconnect the wire leads from the connector.

C. Remove the ice damper and water distribution

tube.

• Remove thumbscrew from bin switch cover.

• Support ice damper and then pull bin switch cover and

ice damper forward to remove.

• Remove thumbscrews from the water distribution tube,

then remove.

Remove Thumbscrew From Bin Switch Cover,

Support The Damper, and Remove

Remove Thumbscrews From Distribution Tube and Remove

Summary of Contents for Manitowoc NEO U0140 Series

Page 2: ......

Page 16: ...16 Part Number 040005890 Rev 04 02 19 Operation Section 3 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 23: ......