Part Number 020002365 08/25/2015 33

Section 3

Operation

Sequence of Operation

ELECTRONIC CONTROL

Prerequisites

• Potable water must be connected to the carbonator

pump circuit.

• The ice bank water bath water must cover the

evaporator. The compressor will not start unless the ice

bank control probes are immersed in water.

• CO

2

must be supplied.

Initial Power-up

The control has a 30-second delay when power is

connected, or disconnected and reconnected. The display

will show Pd30 - power delay and 30 seconds left in the

countdown cycle.

Normal Operation

NOTE: This sequence of operation includes systems with up

to two recirculation/carbonation circuits. Your model may

not employ a second circuit or second carbonation pump.

Pressing the COMP/AGIT button will start the water

bath agitator immediately and initiate the 180 second

compressor delay. The display will show Cd99 (compressor

delay & 99 seconds) and will start to count down from 99

seconds after the first 81 seconds have elapsed. After 180

seconds the compressor and condenser fan motor energize

and the COMP/AGIT LED flashes. Pressing the CARB A and

CARB B buttons will power the carbonator tank liquid level

control. The corresponding LED flashes to indicate the

pump is running. Pressing the CIRC A & CIRC B buttons will

immediately energize the circulating pumps and energize

the LED constantly. The display will show the circulating

temperature and show the A circuit. When two circuits are

used, the readout will alternate between A and B circuits

every 5 seconds.

The compressor and condenser fan will continue to run

until ice contacts the ice bank control probe closest to the

evaporator. When ice contacts the probe, the COMP/AGIT

LED lights constantly and the compressor and condenser

fan motor de-energize.

As the ice bank melts, the ice bank control probe will lose

contact with the ice; the LED will flash and the compressor

and condenser fan motor will restart. This cycle will repeat

as required depending on load.

Power Interruption

During a power interruption the control will resume from

the point of interruption when power is reapplied and the

time delay expires. Any switches/components that were

energized when power was interrupted will be energized

when power is reapplied.

Error Codes

E1 = Low Water Supply Pressure

E2 = Low CO

2

Pressure

E3 = Low Water Level - Water Bath

E4 = High Water Bath Temperature

E5 = High Water Supply Pressure

E6 = High Refrigeration Temperature

E7 = High Ice Bank Size (Probe Sensor 2)

E8 = Long Carb A Run Time

E9 = Long Carb B Run Time

NOTE: Shorted Transducer = “----”

Open Transducer = “====”

Error codes will display until corrected.

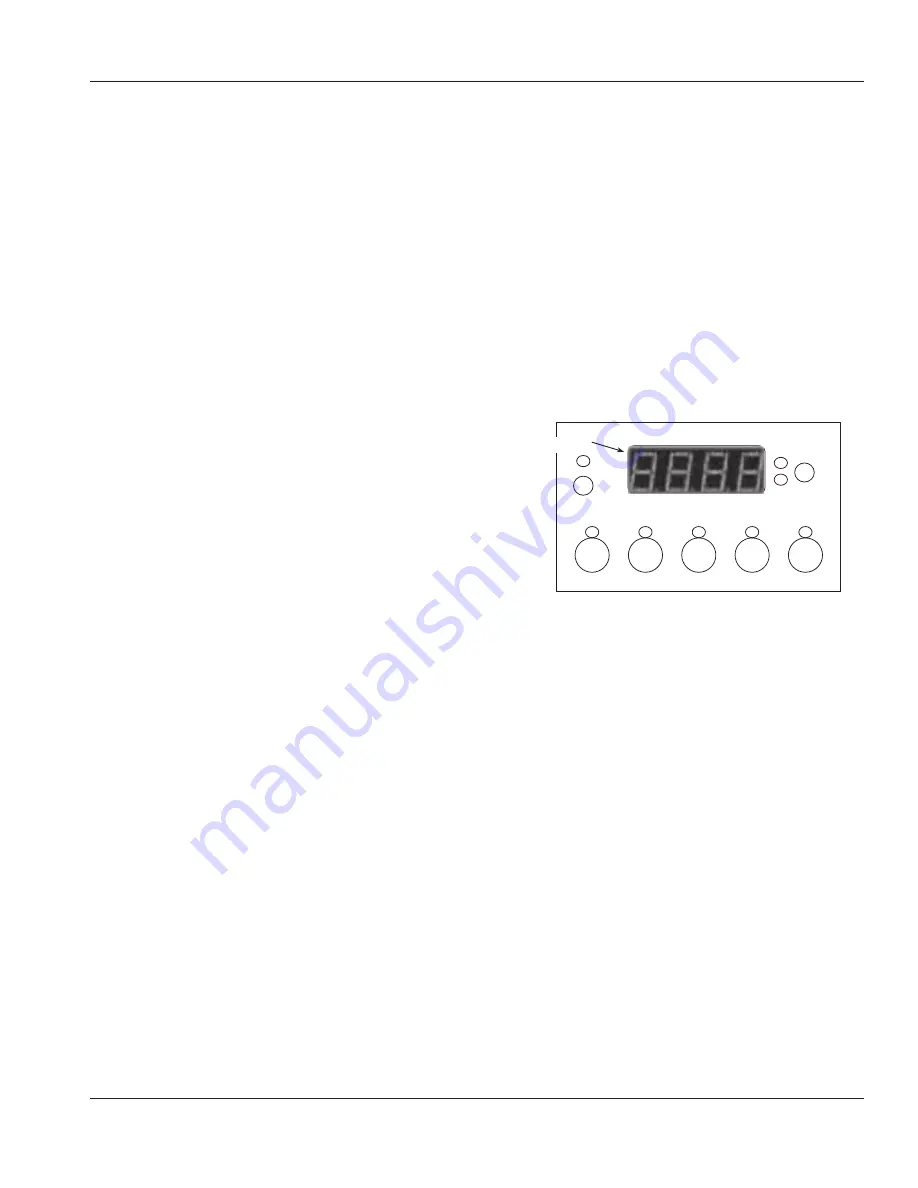

SER

PGM

CIRC

B

CIRC

A

COMP/

AGIT

CARB

A

CARB

B

CIRC

A

CIRC

B

LED Display

Control Programming

There are 5 programming modes:

1. Used to check probes, water bath level, set unit of

measure, & check temperatures.

2. Add additional (third or fourth) circulation pumps

3. For Beermaster Units only - Sets water/glycol

temperature.

4. Temporarily cancel display of error codes.

5. Energy Saving Mode. (G Series Models)

SER Switch

• For when optional LON communication network is

connected.

PGM Switch

• Used to enter and exit programming modes. To enter,

press and hold switch for 3 seconds, repeat to exit.

ū

Press and hold Carb B switch — Display will

indicate

CO

2

Pressure