16.08.2013

2

MANKAR HQ

Noise emission from the unit equates to less than 70 dB (A).

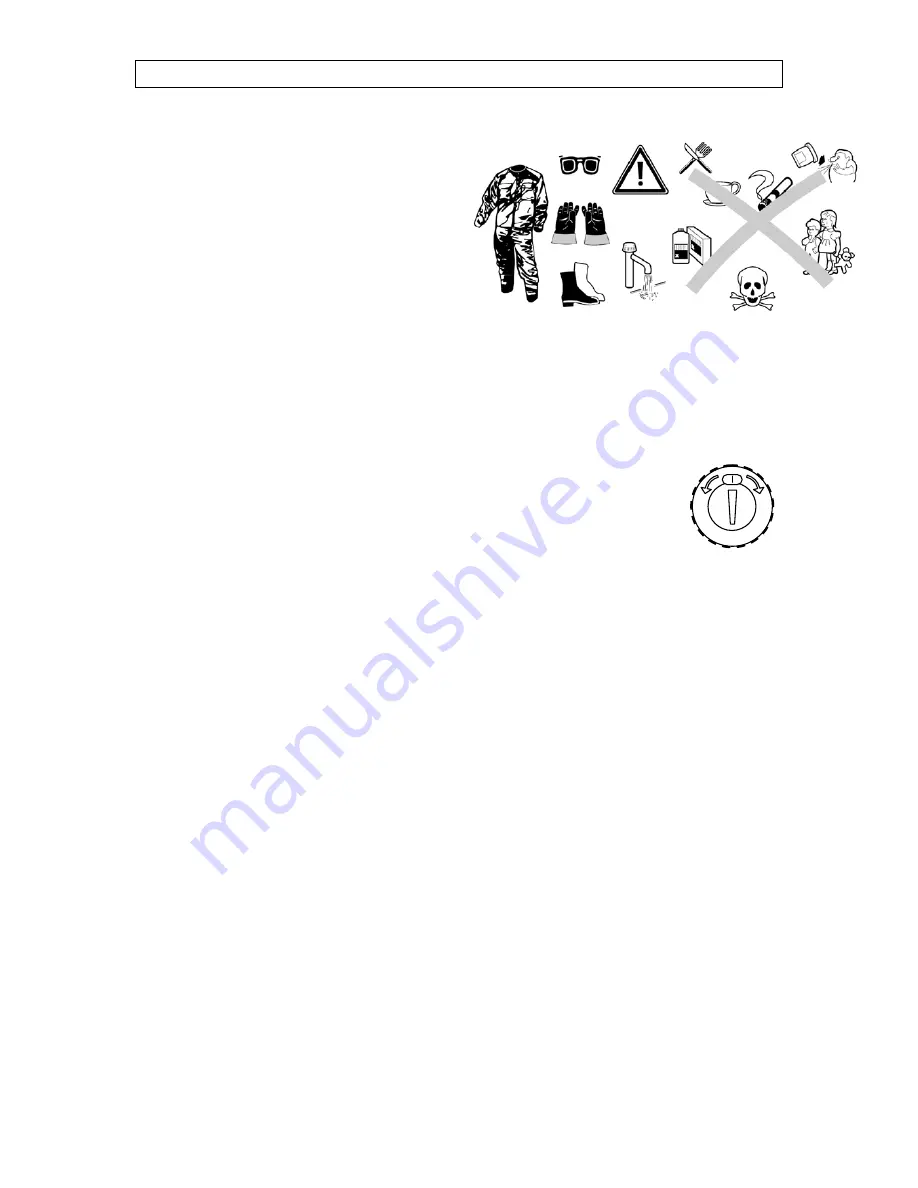

Protective measures

Observe remarks in the usage instructions for the

pesticide regarding the safety of the user; wear

recommended body protection. Wear protective gloves

when filling the chemical.

Do not eat, smoke or drink while working with

pesticides.

Avoid chemical spillage without fail. After completion of the

work, thoroughly clean hands and face.

Thoroughly clean and dry the unit immediately following its

usage. Never use the mouth to blow out nozzles or other

small parts!

Keep pesticides and applicators away from children.

Assembly and preparation for the first application

Assembly of this unit is described on page 3.

Before the first application of the unit, allow the battery to charge for at least 8 hours. First plug the applicator plug into the

loading socket, then plug the charging device into the 230 V power outlet. After ca. 8 hours charging time, the battery has

reached its full voltage capacity. When the charging process is complete, first unplug the charging device from the 230 V

power outlet, then unplug the unit plug from the charger socket.

The spray width should be subsequently checked - ideally with a piece of cardboard laid out on the ground - and the flow

rate adjusted. If the unit is switched on the battery monitoring LED lights green (fig. page 3/4)

Before using the MANKAR HQ the breather hole of the lid has to be opened.

If the air-vent is closed there won’t be an even chemical flow.

After usage the breather hole has to be closed to prevent leaking.

General remarks about the function and regarding the application of the unit

Pesticides:

This applicator was originally designed for the undiluted application of Roundup products (Glyphosate).

Practical experience has shown, however, that other herbicides can also be deployed in conjunction with this technology.

Considering the many products on the market with their differing formulations, it is not possible to provide a complete list

with application rate recommendations. The specifications depicted below for adjusting the applicator relate to the usage of

Roundup UltraMax (Glyphosate 450 gr/ltr). In general, all products with a comparable viscosity are suitable. If you intend to

use a product other than Roundup UltraMax, its application should be initially tested on a trial basis over a small area. In

any case, the usage instructions for the chosen herbicide should be observed along with the local requirements.

Because of the compatibility with the materials used never use aggressive, solvents containing cleaning agents or gasoline.

Applicator function:

The rotating atomiser is driven by means of a rechargeable battery. Metering takes place by means of

a metering valve. Droplets are formed by the centrifugal force of the rotating atomiser. The droplets are discharged

downwards by the rotating atomiser through a step-free, adjustable segment. The residual chemical in the tank, not able to

be applied, is approximately 10 ml. This residual fluid can be refilled back into the original herbicide container.

Checking applicator function:

Chemicals can flow at differing rates, more quickly or slowly, due to temperature variations.

For this reason, the flow rate depicted in the metering table must be checked and corrected as necessary. This technology

is not suitable for the application of water. Always use herbicides for testing the spray process and for calibrating the flow

rate. Check the rotating atomiser for cleanliness and free turning movement on a daily basis. Check the application volume

from time to time throughout the season.

Deployment of the applicator:

Position the spray hood directly above the ground - if the spray hood is held too high, the

danger of spray driftage exists. During operation, chemical fluid will collect in the atomiser reservoir and can continue to drip

for few seconds after pressing the switch- valve unit. Make sure that the valve of the bottle lit is open before use. After

usage close the valve again to provide leakage.

Attention!

If there is any leakage the stop working and repair the unit.

Before lifting or tilting the spray hood, it is essential that the stop valve is closed and the atomiser motor is switched off.

Cleaning:

It is common practice that spraying systems need a minimum of service and maintenance same applies for the

MANKAR HQ. Rinse the unit with warm clear water. To accelerate the cleaning procedure a cleaning agent like “tank-

cleaner” can be used. Regular cleaning reduces sediments and prevents obstructions of the valve and blocking of the

atomizer.

1= open

0= closed

Draft of the bottle lid