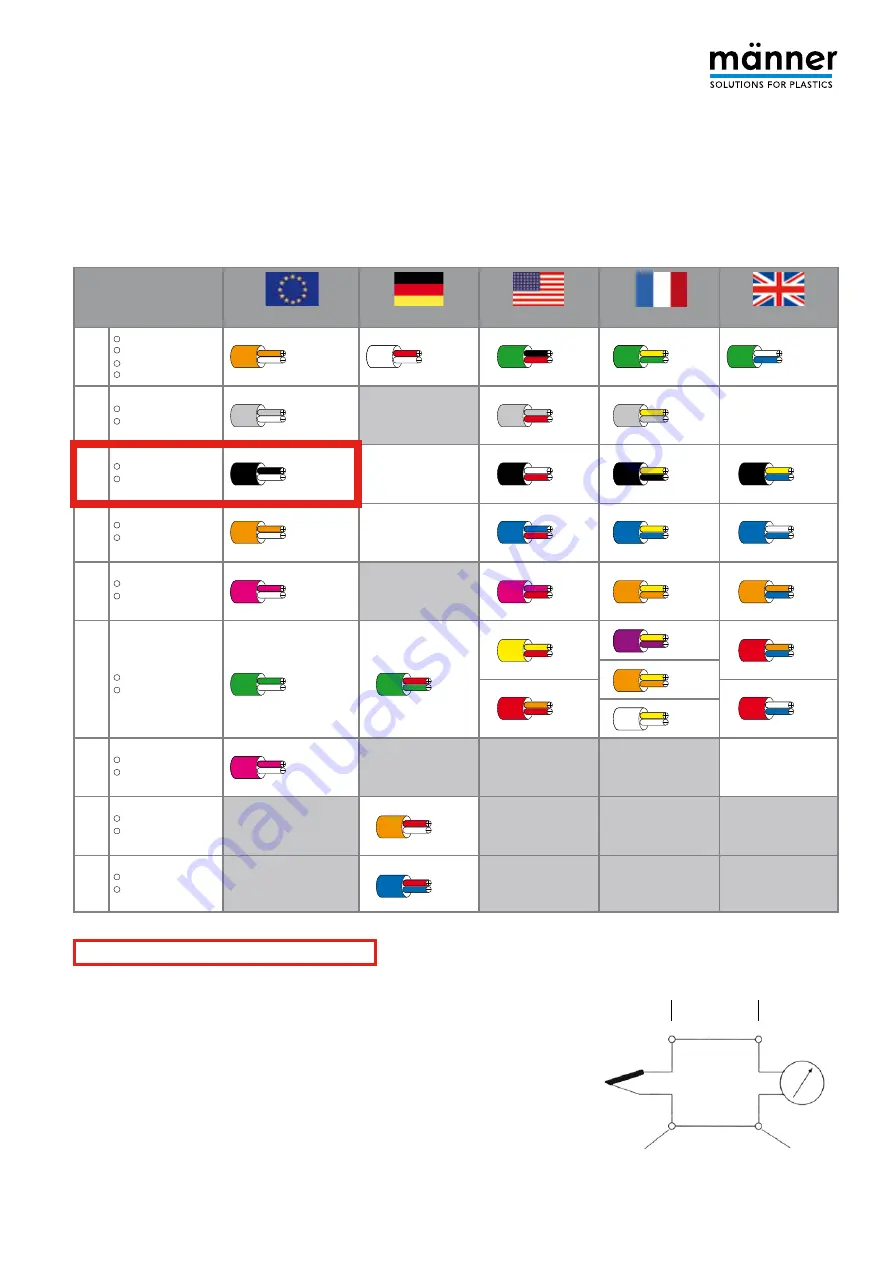

comPensaTinG caBles

To ensure proper temperature measure-

ment, please note the following.

When connecting the hot (measuring)

junction to the cold (reference) junction

in the control unit, make sure you use

a compensating cable whose wires are

made of original thermocouple material.

Explanation: Wires made of original

thermocouple material exhibit the

same thermoelectric behavior as the

thermocouple pair at the hot junction.

As a result, the thermocouple voltage

remains constant all the way to the cold

junction in the control unit.

This cold junction compensation is

necessary, since thermocouples measure

the temperature difference between the

hot junction and the cold junction (see

diagram on right). This helps to prevent

parasitic thermocouple voltages.

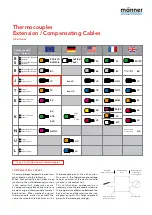

Thermocouples

extension / compensating cables

Overview

* Type J is used for männer thermocouples.

Thermocouple

T

e

K

n

u

l

Type material

IEC 60584

DIN IEC 584

DIN 43710

BC 4937

see lX

see uX

Color coding

not specified

Color coding

not specified

rX/sX

BX

JX

TX

eX

KX

VX

nX

r

s

B

J

Iron

Copper-nickel

Copper

Copper-nickel

Nickel-chromium

Copper-nickel

uX

lX

soPtrh/

soPt

sX

BX

JX

TX

eX

KX

VX

JX/Jc

TX/Tc

eX/ec

KX/Kc

Bc

sc

Vc

Wc

NF-C 42-324

ANSI MC 96.1

rca/sca

rcB/scB

Bc

JX

TX

eX

nX/nc

KX

KcB

Kca

NiCr

Ni

Fe

CuNi

Insulated

thermocouple wire

Measuring unit

of hot runner

control system

Compensating

wire

Plug connector or

direct connection

Cold junction

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

Nickel-chromium

Nickel

Nickel-chromium-silicon

Nickel-silicon

Copper

Copper-nickel

Iron

Copper-nickel

Platinum/20% Rhodium

Platinum/6% Rhodium

Platinum/13% Rhodium

Platinum

Platinum/10% Rhodium

Platinum