3

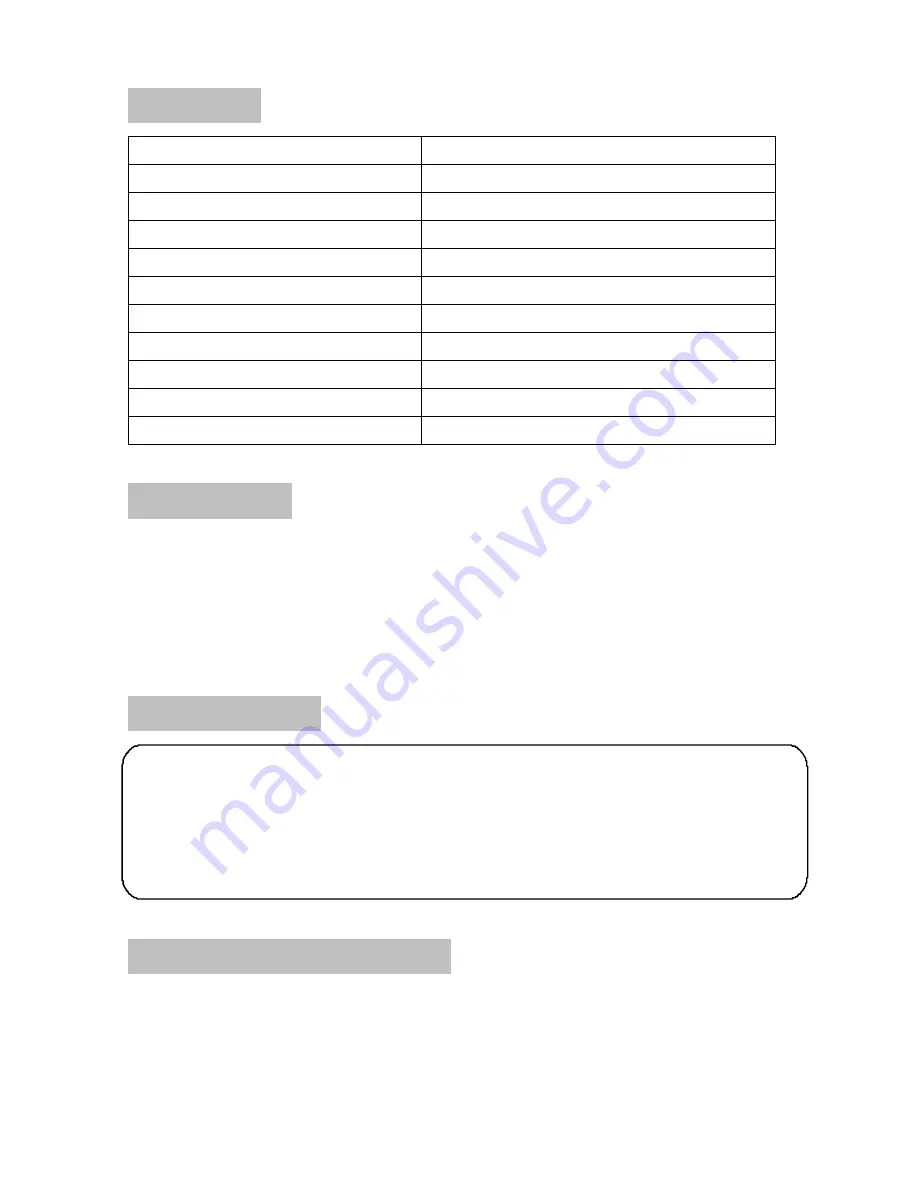

Specifications

Function

collect waste oil from vehicle gear box or engine

Power Compressed

air

Air Consumption

About 200L/min

Air Inlet Pressure

87~116PSI/6~8Bar

Oil ejection pressure

10~14PSI/0.7~1Bar

Vacuum Degree

0 ~ -14PSI/0~-1Bar

Tank Capacity

70L

Perspex cylinder Capacity(Practicable/total)

9/10L

Collect tray capacity

16L

Height About

1350mm~1750mm

Working Temperature

40~60

(for engine oil)

℃

Save this manual

You will need the manual for the safety warnings and precautions, assembly instructions, operating and

maintenance procedures, parts list and diagram.

Keep your invoice with this manual.

Write the invoice number on the inside of the front cover.

Keep the manual and invoice in a safe and dry place for future reference.

General safety rules

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow all

instructions

listed below may result in electric shock, fire, and/or serious

injury.

SAVE THESE INSTRUCTION

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed

to reduce the risk of personal injury and damage to equipment.

1.

Keep work area clean. Cluttered areas invite injuries.