7

DISPENSING VOLUME TUBING REQUIREMENTS

The table below gives an average range of volumes dispensed, measured with water at standard pressure and temperature

using silicone tubing.

*Requires tubing links.

OPERATION

Use only MANOSTAT precision tubing with MANOSTAT pumps to ensure optimum performance. Use of other

tubing may void applicable warranties.

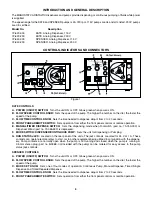

INSERTING TUBING

WARNINGS: Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures to

protect operator and equipment.

Turn pump off before removing or installing tubing. Fingers or loose clothing could be caught in

the pump mechanism.

1. Make sure that the power switch is turned OFF.

2. Remove the two thumb nuts, and then remove the clear plastic cover from the pump head.

3.

For Tubing Links:

Attach input and output ends of the transfer tubing to the connectors of the tubing link. Insert the

tubing link so that the tie wraps or the flanges of the link are as close as possible to the outside of the pump head.

Manually rotate the roller assembly and guide the tubing between the rollers and the pump head wall.

For Tubing:

Insert tubing between the rollers and the pump head housing in the center of the channel (i.e., midway

between the clear plastic pump head cover and the pump head housing bottom). This ensures that the rollers

depress the entire width of the tubing as they turn. Manually rotate the roller assembly and guide the tubing between

the rollers and the pump head wall. When using tubing (not links), there should be a small but visible gap between

the tubing and the pump head housing for about 1/3 to 1/2 of the contact surface at any time. Pull gently on the input

and output sides of the tubing to create a gap between the tubing and the curved pump head housing wall.

4. Replace the clear plastic cover over the pump head, being sure to tighten down the thumb nuts to prevent the tubing

from moving during operation.

KATE:

The pump head cover is reversible with different size tubing retainers on each face. If the tubing is smaller

than 3/16 in. ID, place the cover so that the larger tubing retainers hold the tubing. If the tubing is 3/16 in. (Size 25)

or larger, reverse the cover.

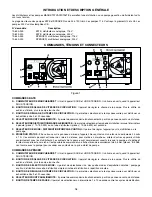

SPENCER:

Adjust the two screws on the retainer clamp to hold the tubing in place after attaching the clear plastic

cover to the pump head. If the tubing is smaller than 3/16 in. ID (Size 25) and a tubing link is not used, do one of the

following to prevent the tubing from creeping in the pump head:

•

Cover the tubing at the clamping points with a small section of a larger tubing to increase the grip.

•

Use a tubing connector on the input of the pump head.

FOR OPTIMUM TUBING LIFE

Periodically move the tubing so that a different segment is in the pump head, or change the tubing link. This will avoid

excessive tubing wear at any specific point. Always move the worn tubing to the suction side of the pump.

Silicone

Tubing Size

Volume Dispensed

KATE

SPENCER

1/32 in ID Tubing*

0.5–12 mL/cycle

0.5–25 mL/cycle

1/16 in ID Tubing*

1.0–35 mL/cycle

1.0–95 mL/cycle

1/8 in ID Tubing

3.5–190 mL/cycle

2.5–320 mL/cycle

3/16 in ID Tubing

14–420 mL/cycle

9–800 mL/cycle

1/4 in ID Tubing

18–710 mL/cycle

13–1250 mL/cycle

5/16 in ID Tubing

35–1070 mL/cycle

20–1700 mL/cycle

Summary of Contents for VARISTALTIC KATE 72-620-000

Page 2: ...2 VARISTALTIC...