15.12.2014

3

Applicator unit function:

Rotating atomisers are driven by means of a rechargeable battery. Metering on all the units

mentioned is path-dependent and takes place by means of a wheel driven pump. Droplets are formed by the centrifugal force

of the rotating atomiser. The droplets are discharged downwards by the rotating atomiser through an adjustable segment.

Residual chemical solution in the tank not intended for application is approx. 50 ml. This residual fluid can be poured back

into the original herbicide container.

Checking applicator unit function:

Chemical solutions may flow quicker or slower due to temperature fluctuations, which is

why the flow rates in the metering table should be checked and corrected as necessary. This system is not suitable for the

application of water. Always use herbicides for testing the spray process and for calibrating the flow rate. Check the rotating

atomiser on a daily basis for cleanliness and free turning motion. Check the output volume from time to time throughout the

season.

Using the applicator unit:

Adjust the height of the spray hood so that it is as close to the ground as possible - if it is set too

high, the risk of spray driftage exists. During operation, chemical solution collects in the rotating atomiser reservoir and will

continue to drip for approx. 30 seconds after the shut-off valve has been closed if the unit is tilted. In order to avoid damage to

cultivated plants due to dripping, we recommend closing the shut-off valve at the end of a row, for example, then folding the

spray hood upwards and waiting approx. 30 seconds until the reservoir has emptied.

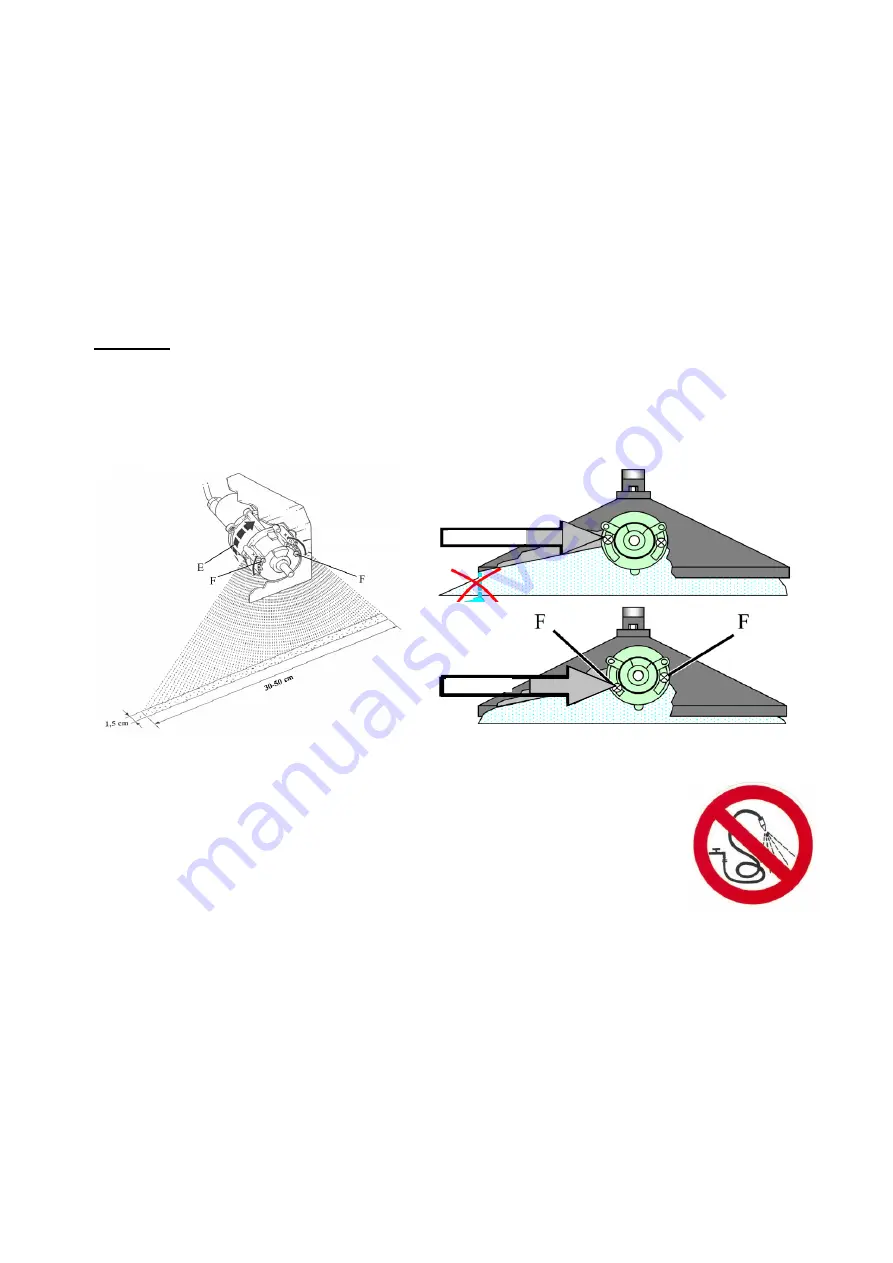

Spray width

•

Place an underlay (cardboard or paper) on the ground and prop up the unit on stands.

•

Actuate the switch button while simultaneously turning the wheel and appraising the spray width obtained, initially at one

location. The spray width must be set so that the droplets are discharged over the entire width of the spray hood. The

optimal spray width under standard operating conditions is set by the manufacturer.

•

In the event of deviations, the screw (F) can be loosened in order to move the width adjustment on the atomiser

(see drawing).

•

Further details regarding operating width adjustment can be found on the pages for the individual applicator units.

Cleaning

Do not clean the applicator unit with a high-pressure sprayer or an intense water jet spray

.

Cleaning during the season:

During short work breaks (a few hours), herbicide can remain

in the system as long as the shut-off valve remains closed. After work completion: Before

cleaning, drain the chemical solution and pour it back into the original container. Open the

shut-off and set the metering pump to maximum. Fill the chemical solution tank up to halfway

with water, then, with the unit positioned, turn the wheel smoothly approx. 50 x and allow the

fluid to drain into a collector receptacle or, operating the unit for approx. 100 m, apply the

cleaning fluid to the pre-treated surface. Remove any remaining water from the tank and turn

the wheel approx. 50 x again until the system is completely empty.

Cleaning at the end of the season:

Rinse the unit with warm water as described above. The spray hood and the atomiser

housing can be cleaned with a damp cloth. Remove the atomiser disc in order to avoid damage. In the case of heavy

contamination, the atomiser housing should be unscrewed to remove contaminants and plant parts. Connect the unit to the

charging device (see below).

Charging the applicator unit and battery care

The applicator unit has an automatic charging device. Trickle charging is possible.

Recharging a completely empty battery up to full capacity takes approx. 16 hours.

The battery should be recharged immediately after use.

Battery charge

Min. charging time

Time interval

Fully discharged

16 hours

Immediately

Short-term use

6 hours

Immediately

Storage without use

(2 hours 1 x per month)

or charge continually

With a fully charged battery, units with one atomiser can be used for 16 hours, while units with 2 atomisers can be used for

approx. 8 hours.

INCORRECT

CORRECT