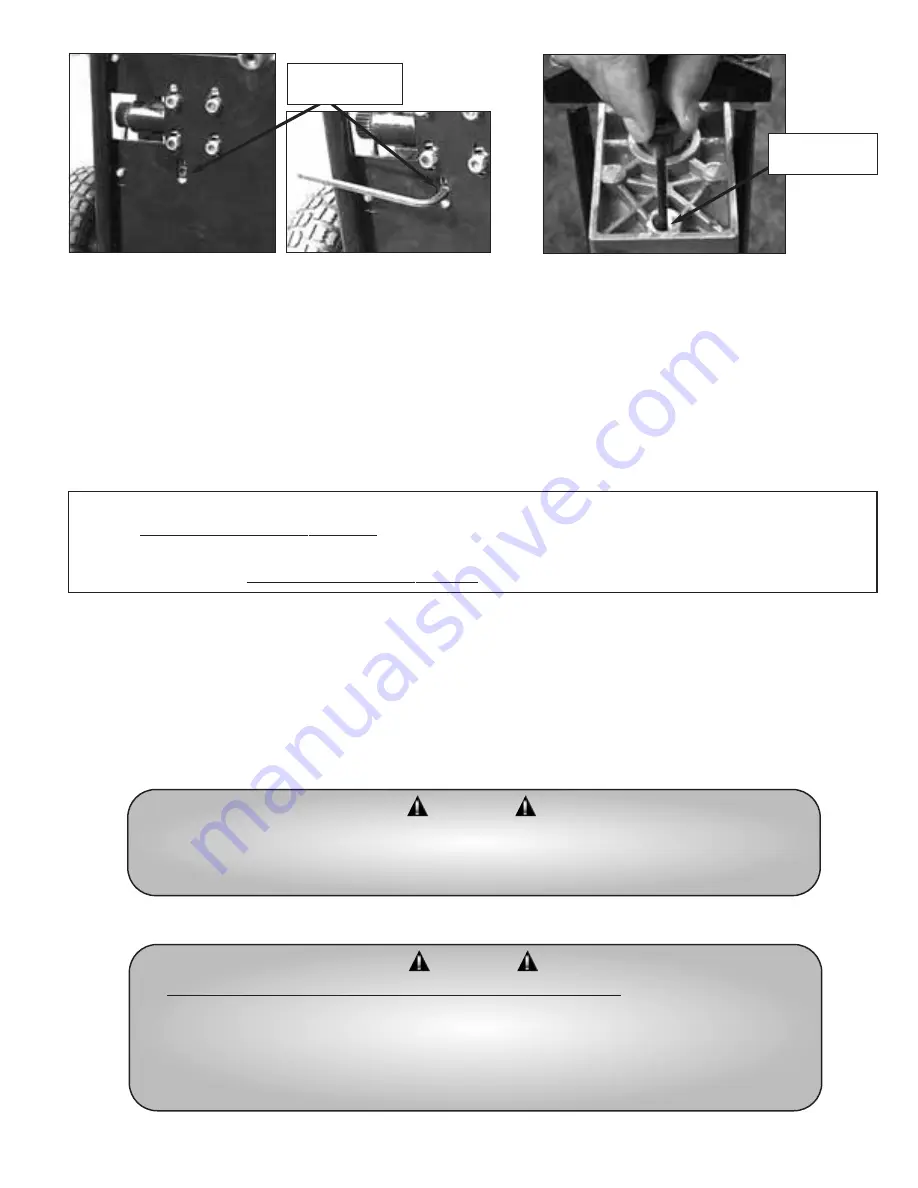

Drain Port

14

IMPORTANT!

IF THE OIL LEVEL IS TOO HIGH THE HEAT WILL NOT BE DISSIPATING QUICKLY ENOUGH

AND THE TEMPERATURE OF THE HYDRAULIC SYSTEM WILL RISE.

IF THE OIL LEVEL IS TOO LOW IT MAY CAUSE CAVITATION*.

• To drain the oil, tip unit back, place an empty container that can hold at least 1 Gallon (4 Liters) of oil under the

log splitter.

• Use an Allen Wrench [P/N 510543 (8mm)] and remove Drain Port Plug and the seal in the aluminum bottom cover plate

of the log splitter.

• Hold the handle, move unit up a little and position it under the angle. Using an Allen Wrench, unscrew the Dipstick and

open the Oil Fill Port to let air in and help the oil flow out. Wait until the oil completely escapes from the oil reservoir.

• Reinstall the Drain Port Plug and the seal. Be careful not to damage the threads of the Aluminum Bottom Cover.

• After the used oil is drained, pour approximately 0.8-0.9 of a gallon (3-3.3 liters) of recommended oil into the Oil Fill Port.

• Clean the Dipstick and insert it to check the oil level; it should be between the two notches on the stem. If level is low,

add recommended type of the hydraulic oil. If the level is too high, poor out a little at a time into a container.

*Reference:

Cavitation

occurs when the volume of hydraulic fluid demanded by any part of a hydraulic circuit exceeds the volume

of fluid being supplied. If there is an air bubble in the system, the force applied gets used compressing the air in the bubble rather

than moving the piston. This affects the efficiency of the system. In this case, Force (Rated 5 tons) will be cut down.

• Reinstall the Dipstick and the seal. Be careful not to damage the threads of the Dipstick Plug and Aluminum

Top Cover.

• Clean thoroughly.

• Loosen air bleed screw, turn 3-4 times.

• Purge air from the hydraulic system by cycling the pressure plate back and forth 3 to 4 times.

WARNING

DUMPING USED HYDRAULIC OIL IN THE ENVIRONMENT IS FORBIDDEN. THE FLUID

MUST BE DISPOSED IN ACCORDANCE WITH THE LOCAL ENVIRONMENTAL RULES

AND PROCEDURES.

WARNING

BEFORE PERFORMING ANY MAINTENANCE BE SURE THAT:

•

LOG SPLITTER IS DISCONNECTED FROM POWER SOURCE.

•

PUSHER PLATE IS FULLY RETRACTED (RETURNED TO THE LOWEST POSITION)

AND NO RESIDUAL HYDRAULIC ENERGY IS LEFT IN THE SYSTEM.

•

OIL HAS COOLED.

J. Sharpening the wedge

Sharpen the splitting wedge, as needed, using a fine-toothed file to remove any burrs, nicks or flat spots from the wedge.

Oil Fill Port