.

Maple Systems Inc., 808 134th Street SW, Suite 120, Everett, WA 98204-7333

1036-0203

Page 3 of 4

Rev. 01, 10/11/2015

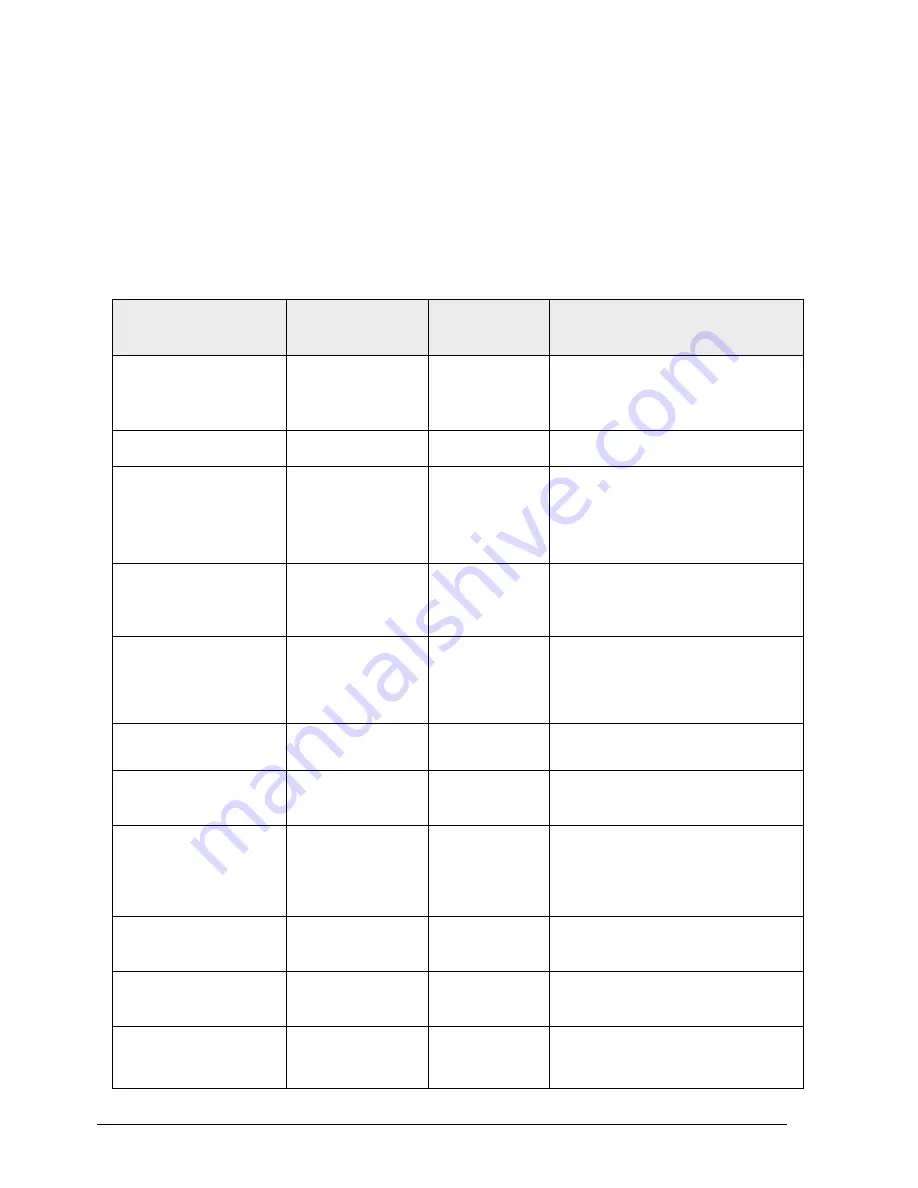

EZware Settings

The following table lists the communications settings that must be configured in

EZware. These settings can be found in the

Edit-System Parameters

menu under the

Device

Properties

tab. Please note:

The

Recommended Settings

column provides the recommended setting

based upon the default settings most commonly used in Siemens modules.

The

Options

column lists EZware’s options; your PLC may not support

every option

Name

Recommended

Settings

Options

Important Notes

Name:

Siemens S7-200

Smart (PPI)

Description label

HMI or PLC

PLC

Location

Local

Local, Remote

Select

Local

if PLC directly

connected to HMI,

Remote

if PLC connected thru

another HMI.

PLC type:

Siemens S7-200

Smart (PPI)

PLC I/F:

RS485 2W

RS-232,

RS-485 2W,

RS-485 4W

Must match the controller port

setting.

PLC default station

no.:

2

1-126

Must match the node address

assigned to the PLC.

Setting: COM:

COM1

COM1-COM3

Serial port of the HMI connected

to the controller.

Settings: Baud rate

9600

9600, 19200,

187.5K

Must match the PPI port

setting. Use the fastest

baud rate supported by the

controller.

Settings: Data Bits

8

7 or 8

Must match the PPI port setting.

Settings: Stop Bits

1

1 or 2

Must match the PPI port setting.

Settings: Parity:

Even

Even, Odd,

None

Must match the PPI port setting.