1. Safety Warnings

WARNING Hazardous location environment

. This unit is suitable

for use in Class I, Division 2 groups A, B, C and D or Non-Hazardous

locations only.

WARNING

All input and output (I/O) wiring must be in accordance

with Class I, Division 2 wiring methods and in accordance with the

authority having jurisdiction.

WARNING Explosion hazard.

Do not disconnect equipment unless

power has been switched off or the area is known to be non-hazardous.

WARNING Explosion hazard.

Do not connect more than one main

power supply to any one fuse or circuit breaker.

WARNING Explosion hazard.

Substitution of components may

impair suitability for Class I, Division 2.

1.1. Hazardous Locations

Install the MicroOIT terminal using publication NFPA 70E, Electrical Safety

Requirements for Employee Workplaces as a guide. Be certain to follow all

directions for installing and connecting DC power to the MicroOIT.

When used in a hazardous environment, the ultimate enclosure must be in

accordance with Class I, Division 2 wiring methods as described in the National

Electrical Code (ANSI/NFPA 70).

All peripheral equipment must be suitable for the location in which it is used.

Use only a Class 2 power source as described in the National Electrical Code

(ANSI/NFPA 70).

WARNING

Use only with Class 2 power source limited to 30 VDC

open circuit and 8A short circuit.

1010-0104, REV 03

6

OIT3185A/4185A

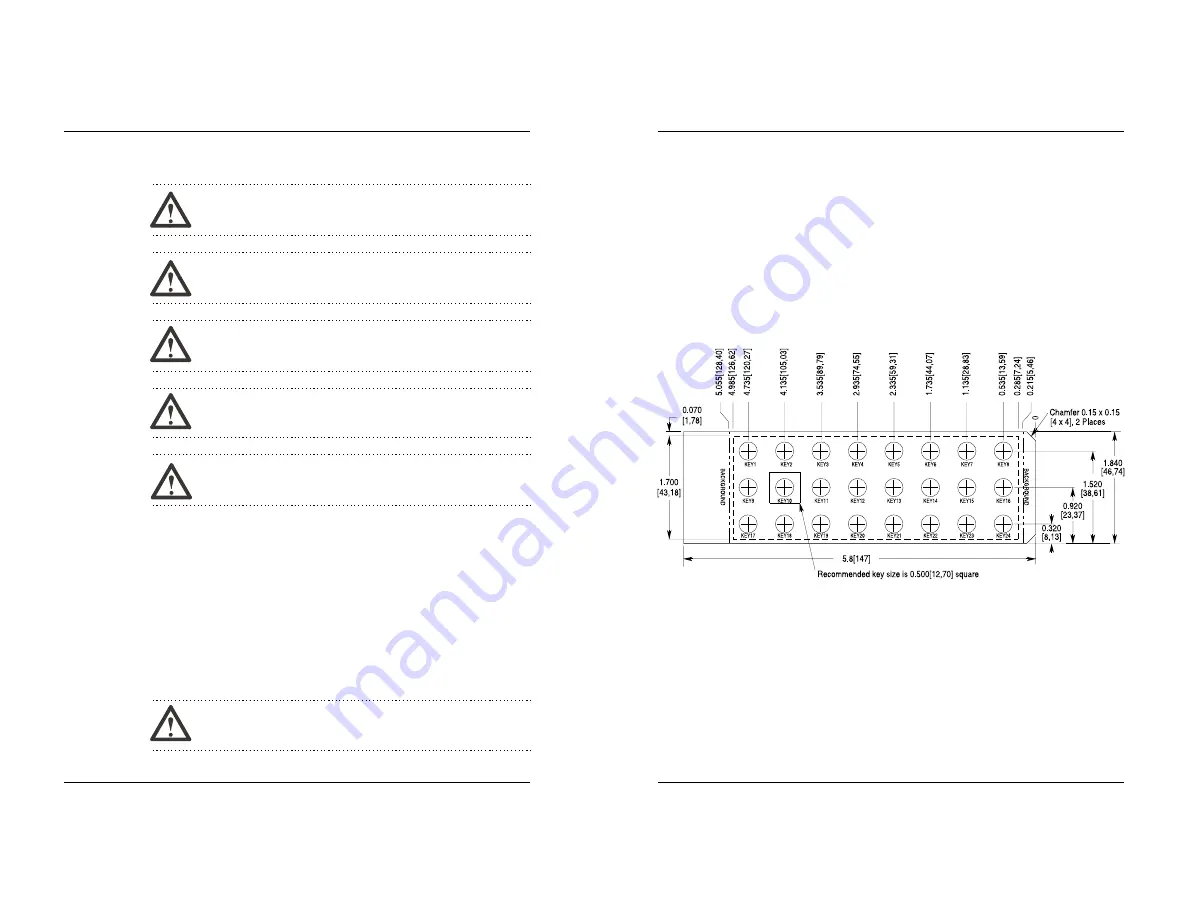

5.3. Creating a Computer-Generated Slide-In Legend

The dimensions in Figure 10 can be used to create a computer generated legend.

When creating:

• Dimensions are in inches [mm].

• Recommended key size is 0.500 inches [12.7 mm] square.

NOTE:

Pressing the center of the switch is critical for switch actuation.

• Background colors should extend to the upper and lower edges of the legend and

to the 2 vertical lines marked “BACKGROUND.”

• All text and graphics should be within the dashed rectangle.

When printing:

• Use only non-glossy stock which is 0.004 - 0.008 inches (0.1 - 0.2 mm) thick.

• Check printing accuracy with the printed check dimension.

INSTALLATION MANUAL

19

1010-0104, REV 03

Figure 10 Computer-Generated Legend Dimensions