4.

Select the

data format.

5.

In the Attribute frame, select how you want the Set Word object to operate:

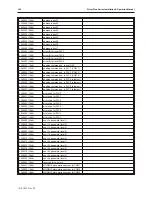

Write Constant Value

When touched, sets the Write Address to the specified value.

I

ncrement Value (JOG+)

Each time it is touched, increments the value in the Write Address by the value specified by Inc.

Value, up to the value specified by Upper Limit.

Decrement Value (JOG-)

Each time it is touched, decrements the value in the Write Address by the value specified by Dec.

Value, down to the value specified by Bottom Limit.

Press and Hold Increment

(JOG++)

When touched, increments the value in the Write Address by the value specified by Inc. Value, up

to the value specified by Upper Limit. When held for the time specified by Jog Delay, continues to

increment the value in the Write Address, at the rate specified by Jog Speed.

Press and Hold Decrement

(JOG—)

When touched, decrements the value in the Write Address by the value specified by Dec. Value,

down to the value specified by Bottom Limit. When held for the time specified by Jog Delay,

continues to decrement the value in the Write Address, at the rate specified by Jog Speed.

Periodic JOG++

Increments the value in the Write Address by the value specified by Inc. Value, up to the value

specified by Upper Limit, at the rate indicated by Time Interval.

Automatic JOG—

Decrements the value in the Write Address by the value specified by Dec. Value, down to the

value specified by Bottom Limit, at the rate indicated by Time Interval.

Periodic Bounce

Similar to Periodic Jog++, except that the value begins decrementing when it reaches the Upper

Limit. Then, the value begins incrementing again.

Periodic Step Up

Starting with the value in the Low Limit box, increments the value in the specified register by 1,

until the value in the High Limit box is reached, at the rate specified by the Time Interval. When

the High Limit is reached, the register value is reset to the Low Limit, and the incrementing

repeats.

Periodic Step Down

Starting with the value in the High Limit box, decrements the value in the specified register by 1,

until the value in the Low Limit box is reached, at the rate specified by the Time Interval. When

the Low Limit is reached, the register value is reset to the High Limit, and the decrementing

repeats.

Set When Window Opens

Sets the Write Address to the value specified by Constant, when the Window containing the

Object is displayed.

Set When Window Closes

Sets the Write Address to the value specified by Constant, when the Window containing the

Object is closed.

Set When Backlight On

Writes the specified value to the Write Address when the Backlight turns on.

Set When Backlight Off

Writes the specified value to the Write Address when the Backlight turns off.

6.

Refer to the Bit Lamp Object section for information on using the

Shape

tab. Note that it is

not required to use a shape or a bitmap. In some modes such as

Set at window open

or

Periodical JOG++

you may prefer to place the part on the window without a shape or bitmap

tied to it.

7.

Refer to the Bit Lamp Object section for information on using the Label tab.

8.

Click

OK

. The New Set Word Object dialog closes and the main screen of EasyBuilder

appears with the cursor tied to a rectangular outline of the part you just created at the upper

left corner of the screen. Move the part to the desired location on the window.

9.

Once the part is placed onto the window, you can adjust the location of the label inside the

part by clicking once on the label. This will highlight the entire object. Click on the label

again. Now only the label is highlighted, allowing you to move it without moving the part.

Note: if you double-click (click twice rapidly) then you will not highlight the label but rather

enter the Set Word Object’s Attribute dialog box.

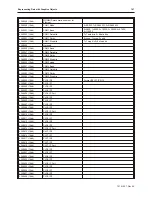

The Slider Object

The slider object is used to write data to a PLC Register. It also reflects the value in the PLC register. Data is written

to the register when the slider is released. The following data formats are supported:

• 16-bit BCD

• 32-bit BCD

• 16-bit Unsigned

• 16-bit Signed

• 32-bit Unsigned

1010-1007, Rev 05

180

Sil ver Plus Se ries In stal la tion & Op er a tion Man ual

Summary of Contents for Silver Plus Series

Page 20: ...1010 1007 Rev 05 16 Silver Plus Series Installation Operation Manual ...

Page 31: ...COM Ports for the HMI5056 5070 1010 1007 Rev 05 Connect the OIT to the PLC or Controller 27 ...

Page 38: ...1010 1007 Rev 05 34 Silver Plus Series Installation Operation Manual ...

Page 49: ...7 Click the Shape tab 1010 1007 Rev 05 Creating Your First Project 45 ...

Page 62: ...1010 1007 Rev 05 58 Silver Plus Series Installation Operation Manual ...

Page 75: ...3 Click OK The System Parameter Settings dialog appears 1010 1007 Rev 05 Using EZware 5000 71 ...

Page 132: ...1010 1007 Rev 05 128 Silver Plus Series Installation Operation Manual ...

Page 156: ...1010 1007 Rev 05 152 Silver Plus Series Installation Operation Manual ...

Page 210: ...1010 1007 Rev 05 206 Silver Plus Series Installation Operation Manual ...

Page 216: ...1010 1007 Rev 05 212 Silver Plus Series Installation Operation Manual ...

Page 246: ...1010 1007 Rev 05 242 Silver Plus Series Installation Operation Manual ...