16-bit Binary

00… to 11… (16 bits)

16 Binary Digits

32-bit Binary

00… to 11… (32 bits)

32 Binary Digits

16-bit Unsigned

0 to 65,537

16-bit Unsigned Integer

16-bit Signed

-32,768 to +32,768

16-bit Signed Integer

32-bit Unsigned

0 to 4,294,967,295

32-bit Unsigned Integer

32-bit Signed

-2,147,483,647 to +2,147,483,647

32-bit Signed Integer

32-bit Float

-9999999999.9999999999 to

9999999999.9999999999

IEEE754 Single Precision

6. Check the

Mask

box to hide the value with asterisks.

7. In the Number of Digits section, select how the data is to be represented.

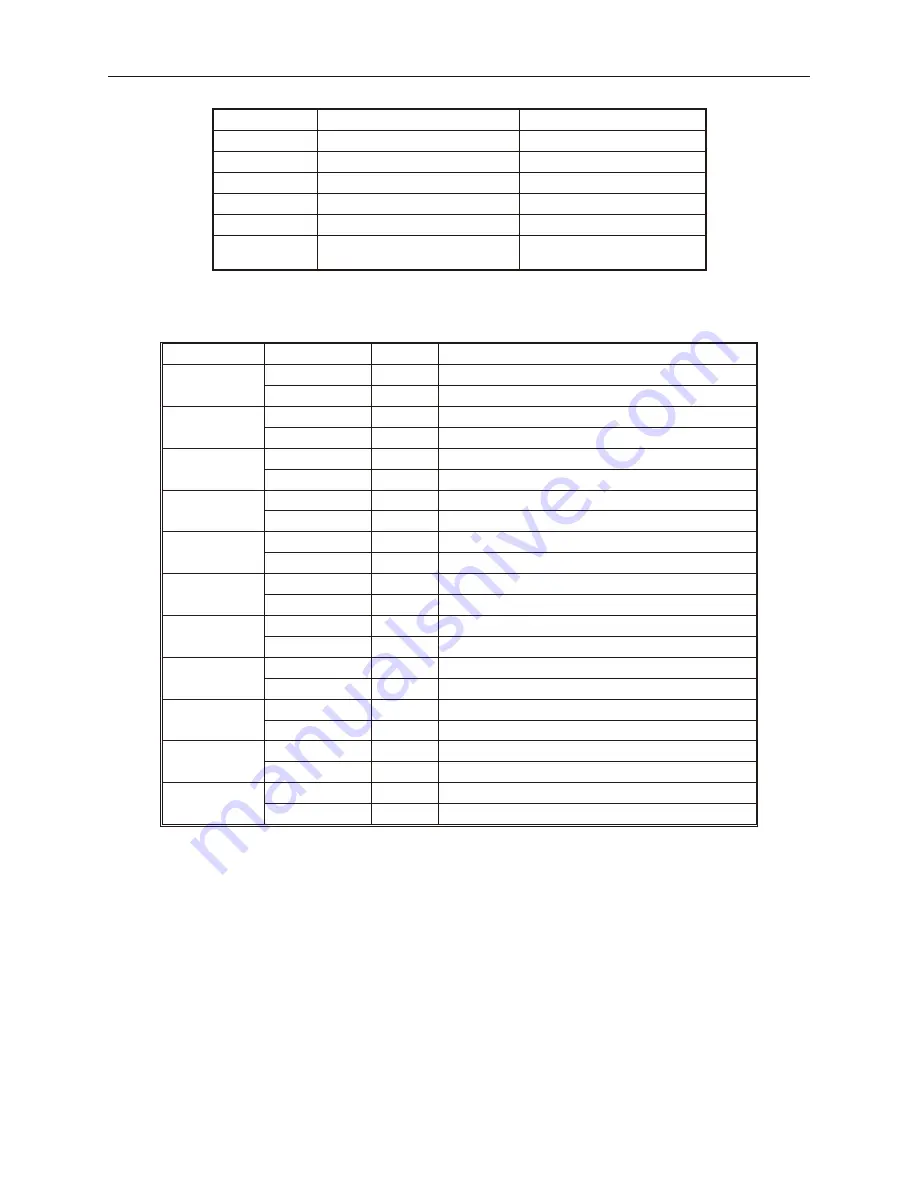

Format

Options

Range

Description

16-bit BCD

Left of Dec. Pt.

1 to 11

Digits to display to the left of the Decimal Point

Right of Dec. Pt.

0 to 11

Digits to display to the right of the Decimal Point

32-bit BCD

Left of Dec. Pt.

1 to 11

Digits to display to the left of the Decimal Point

Right of Dec. Pt.

0 to 11

Digits to display to the right of the Decimal Point

16-bit Hex

Left of Dec. Pt.

N/A

Displays 4 hex digits to the left of the Decimal Point

Right of Dec. Pt.

N/A

No digits are displayed to the right of the Decimal Point

32-bit Hex

Left of Dec. Pt.

N/A

Displays 8 hex digits to the left of the Decimal Point

Right of Dec. Pt.

N/A

No digits are displayed to the right of the Decimal Point

16-bit Binary

Left of Dec. Pt.

N/A

Displays 16 binary digits to the left of the Decimal Point

Right of Dec. Pt.

N/A

No digits are displayed to the right of the Decimal Point

32-bit Binary

Left of Dec. Pt.

N/A

Displays 32 binary digits to the left of the Decimal Point

Right of Dec. Pt.

N/A

No digits are displayed to the right of the Decimal Point

16-bit Unsigned

Left of Dec. Pt.

1 to 11

Digits to display to the right of the Decimal Point

Right of Dec. Pt.

0 to 11

Digits to display to the left of the Decimal Point

16-bit Signed

Left of Dec. Pt

1 to 11

Digits to display to the right of the Decimal Point

Right of Dec. Pt.

0-11

Digits to display to the left of the Decimal Point

32-bit Unsigned

Left of Dec. Pt

1 to 11

Digits to display to the right of the Decimal Point

Right of Dec. Pt.

0-11

Digits to display to the left of the Decimal Point

32-bit Signed

Left of Dec. Pt

1 to 11

Digits to display to the right of the Decimal Point

Right of Dec. Pt.

0-11

Digits to display to the left of the Decimal Point

32-bit Float

Left of Dec. Pt

1 to 11

Digits to display to the right of the Decimal Point

Right of Dec. Pt.

0-11

Digits to display to the left of the Decimal Point

8. The Unsigned, Signed, and Float formats have the option of scaling the data. To display a

scaled value, check the

Do Conversion

box. In the

Engineering Low

field, enter the

lowest

value

that the OIT is to display. In the

Engineering High

field, enter the

highest value

that the

OIT is to display. The conversion will also use the Low and High limits specified in the

Limits section.

9. In the

Limits

section, first select if the Input Low and High values will be entered directly, or

read from a series of PLC registers. If read from a register, the Low Limit is read from the

specified register, and the High Limit is read from the next consecutive register. In either

case, the valid ranges are listed below.

1010-1007, Rev 05

186

Sil ver Plus Se ries In stal la tion & Op er a tion Man ual

Summary of Contents for Silver Plus Series

Page 20: ...1010 1007 Rev 05 16 Silver Plus Series Installation Operation Manual ...

Page 31: ...COM Ports for the HMI5056 5070 1010 1007 Rev 05 Connect the OIT to the PLC or Controller 27 ...

Page 38: ...1010 1007 Rev 05 34 Silver Plus Series Installation Operation Manual ...

Page 49: ...7 Click the Shape tab 1010 1007 Rev 05 Creating Your First Project 45 ...

Page 62: ...1010 1007 Rev 05 58 Silver Plus Series Installation Operation Manual ...

Page 75: ...3 Click OK The System Parameter Settings dialog appears 1010 1007 Rev 05 Using EZware 5000 71 ...

Page 132: ...1010 1007 Rev 05 128 Silver Plus Series Installation Operation Manual ...

Page 156: ...1010 1007 Rev 05 152 Silver Plus Series Installation Operation Manual ...

Page 210: ...1010 1007 Rev 05 206 Silver Plus Series Installation Operation Manual ...

Page 216: ...1010 1007 Rev 05 212 Silver Plus Series Installation Operation Manual ...

Page 246: ...1010 1007 Rev 05 242 Silver Plus Series Installation Operation Manual ...