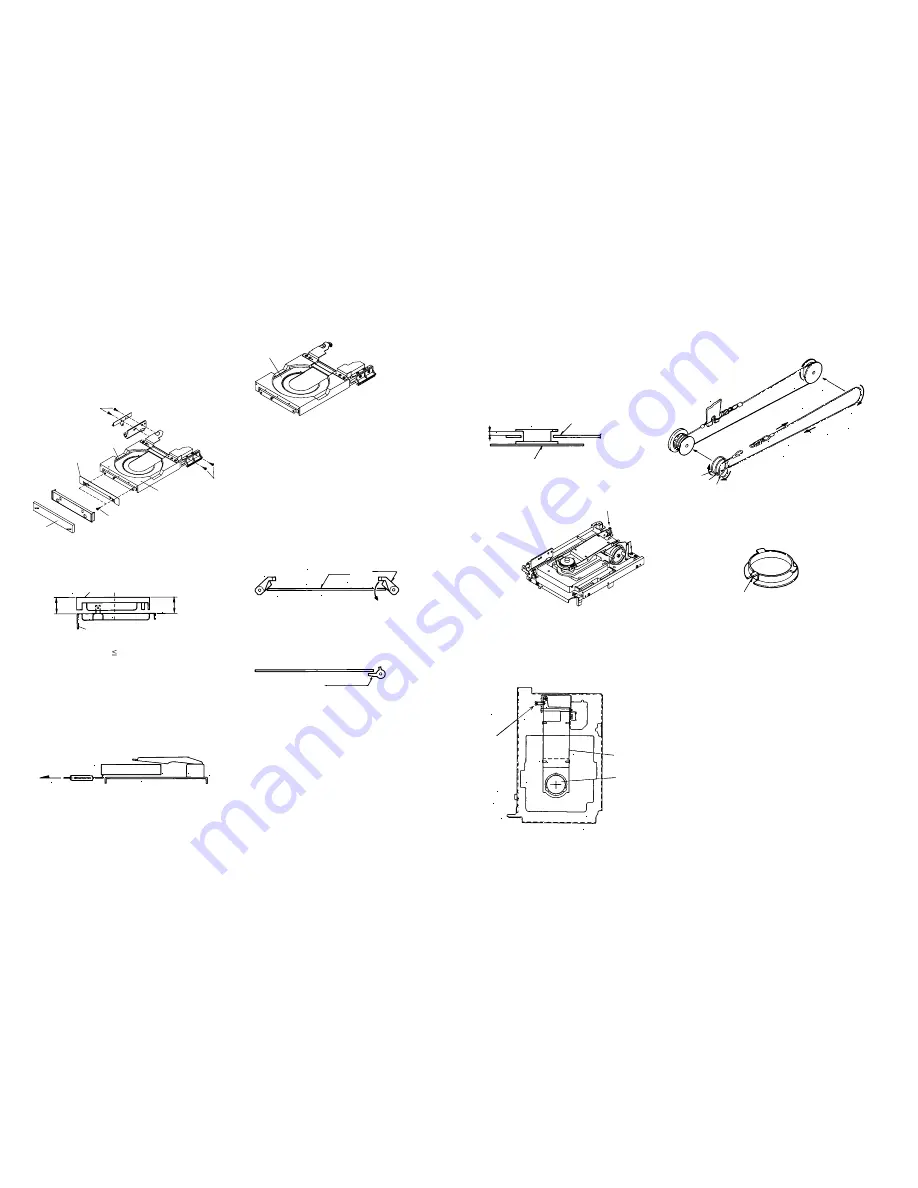

11. TRAY MECHANISM ADJUSTMENTS

1. When mounting tray and tray case

(when replacing tray case because of damage etc.)

a) When the tray has been positioned improperly with a devi-

ated clearance to the front panel window, re-move the tray

lid, loosen screws A and adjust by moving the tray frame

within the range of the holes play.

A

A

A

Tray case

Tray

Tray lid Glass

Tray lid Retainer

For the tray tilt adjustment. refer to the figure below.

Tray case

a

Mechanism chassis

b

Front side

a

=

b

= 29.0 ± 0.2

a

-

b

±0.2

Adjust the tilt with screws A.

b) The operating power of the tray is set to 250 - 350gr (Power

OFF).

250 ~ 350gr

2.When the tray Is disengaged to the lower side

Tray

When the tray is pushed downward without the sub-chassis

(VAM1252), it will be disengaged. So care will be necessary.

(Closing the tray without the sub-chassis also disengages

the tray.)

Mount the tray referring to the figures below.

a) Bring down the lever and put the tray on the protrusion of

lever.

Tray

Lever

b) While holding the tray, bring down the opposite lever and

put the tray on the protrusion of the lever.

Protrusion

Note :

If both the levers are brought down at the same time, the tray

cannot be raised. The levers should be brought down one by

one.

If the tray is forced to move to the original position, the two

pins injected into the tray case may be bent.

3.When replacing the sub-chassis (VAM1252)

a) The height of the sub-chassis turn table is different one by

one. Adjust each turn table height so that the magnet

clamper does not touch the clamper metal strap as shown

in the figure.

Standard ( 1.5+0.3 / -0 mm)

Clamper

metal strap

DISC

1.5 ± mm

0.3

0

Clamper metal

Strap height

adjustment screw

b) After replacing the sub-chassis, readjust so that the mag-

net clamper does not touch the clamper metal strap at

right and left sides. (The clamper metal strap should not

be touched to other straps.)

Clamper arm

adjustment

screw

Clamper arm

Clamper

4.Others

a) For the loading wire winding, refer to the figure be-low.

Wind from inside to outside (1 2 3).

Wind form

inside to outside

1

2

3

b) When the magnet clamper (094M) is replaced, bent the

narrowest tab and remove the clamper.

Bend the narrowest tab.

Bend the narrowest tab

33

34

Summary of Contents for 74 CD7

Page 8: ...7 8 6 WIRING DIAGRAM ...

Page 10: ...9 SCHEMATIC DIAGRAM AND PARTS LOCATION 11 12 ...

Page 11: ...13 14 ...

Page 12: ...15 16 ...

Page 13: ...17 18 ...

Page 14: ...19 20 ...