Service manual April 2017 Qwikbrew 2 version 2

Page 17 of 26

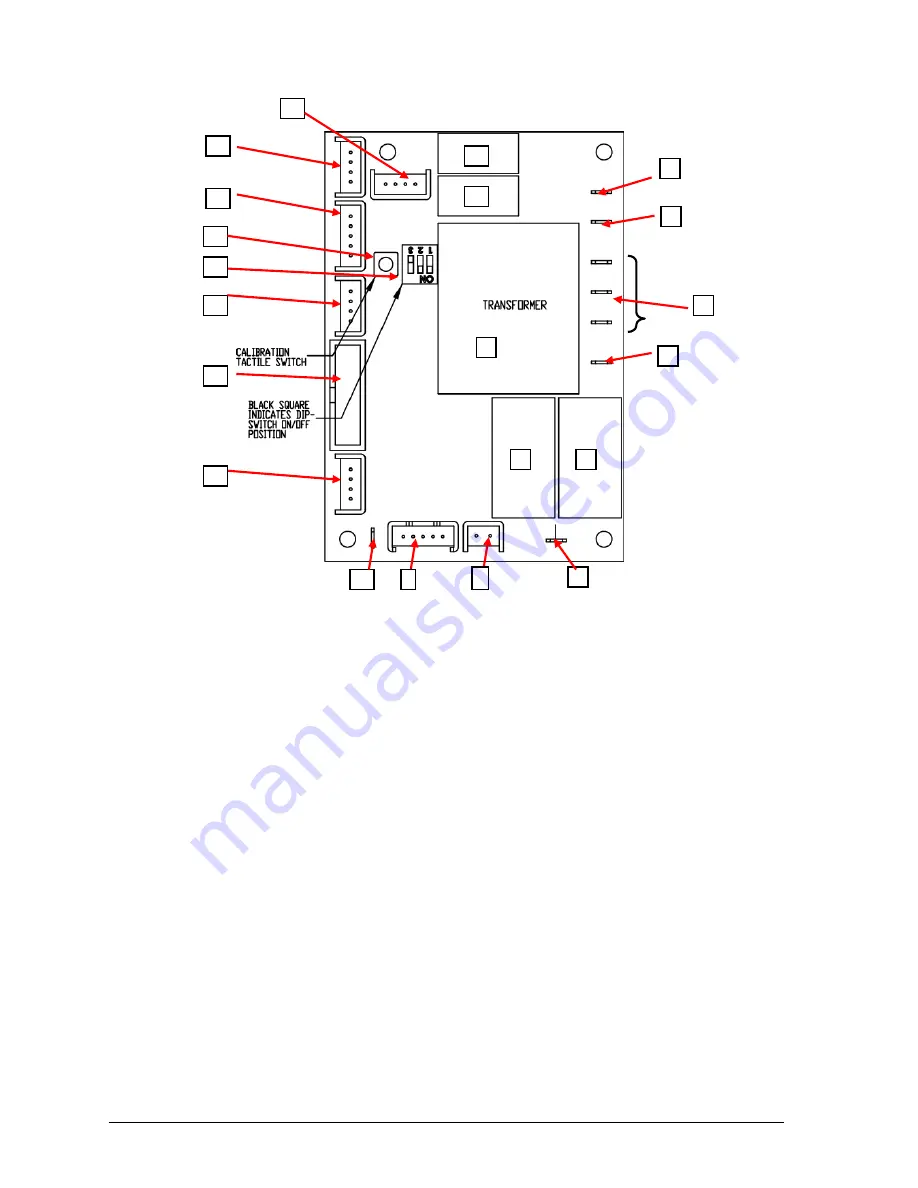

5.3 Main PCB connection identification

3-Brew Main PCB 1600371

1. Dispense Solenoid Tab

2. Inlet Solenoid Tab

3. Neutral Tabs

4. Transformer

5. Mains Live In Tab

6. Relays - Heater

•

Switch the element

7. Heater Tab

8. On/Off 2-way Connector

•

Short circuited on this Ecoboiler machines

– power switch controlled through the display

PCB

9. LED 5-way Connector

10. Earth Tab

11. Daughter PCB Connector (low voltage)

•

Connects to Daughter PCBs

– allows switching of more than one element

12. External Connector

13. Thermistor Connector

14. Dip Switch

– 3 way

•

Allows selection of software for specific machine

15. Tactile Switch

•

For use during calibration procedure (refer to Calibration in Sec 3.3)

16. Water Level

– 5-way connector (low voltage)

•

Connects to Low level and High level probes. Also connects push button on PB variants.

17. Button Connector

– 4-way

18. Data I/O Connector

– 4-way

19. Relays

– Inlet Solenoid

16

17

1

2

3

4

5

7

6

6

11

13

14

15

19

8

9

10

12

19

18

Summary of Contents for Qwikbrew 2 Twin

Page 16: ...Service manual April 2017 Qwikbrew 2 version 2 Page 16 of 26...

Page 19: ...Service manual April 2017 Qwikbrew 2 version 2 Page 19 of 26 Fig 1...

Page 20: ...Service manual April 2017 Qwikbrew 2 version 2 Page 20 of 26 5 6 WIRING DIAGRAM 2 8KW...

Page 21: ...Service manual April 2017 Qwikbrew 2 version 2 Page 21 of 26 5 6 WIRING DIAGRAM 5 6KW...

Page 22: ...Service manual April 2017 Qwikbrew 2 version 2 Page 22 of 26 5 7 PART LISTS QB2 P N1000379...

Page 23: ...Service manual April 2017 Qwikbrew 2 version 2 Page 23 of 26 5 7 PART LISTS QB2 P N1000379...

Page 24: ...Service manual April 2017 Qwikbrew 2 version 2 Page 24 of 26 5 7 PART LISTS QB2 P N1000379...