9

Mareli Systems

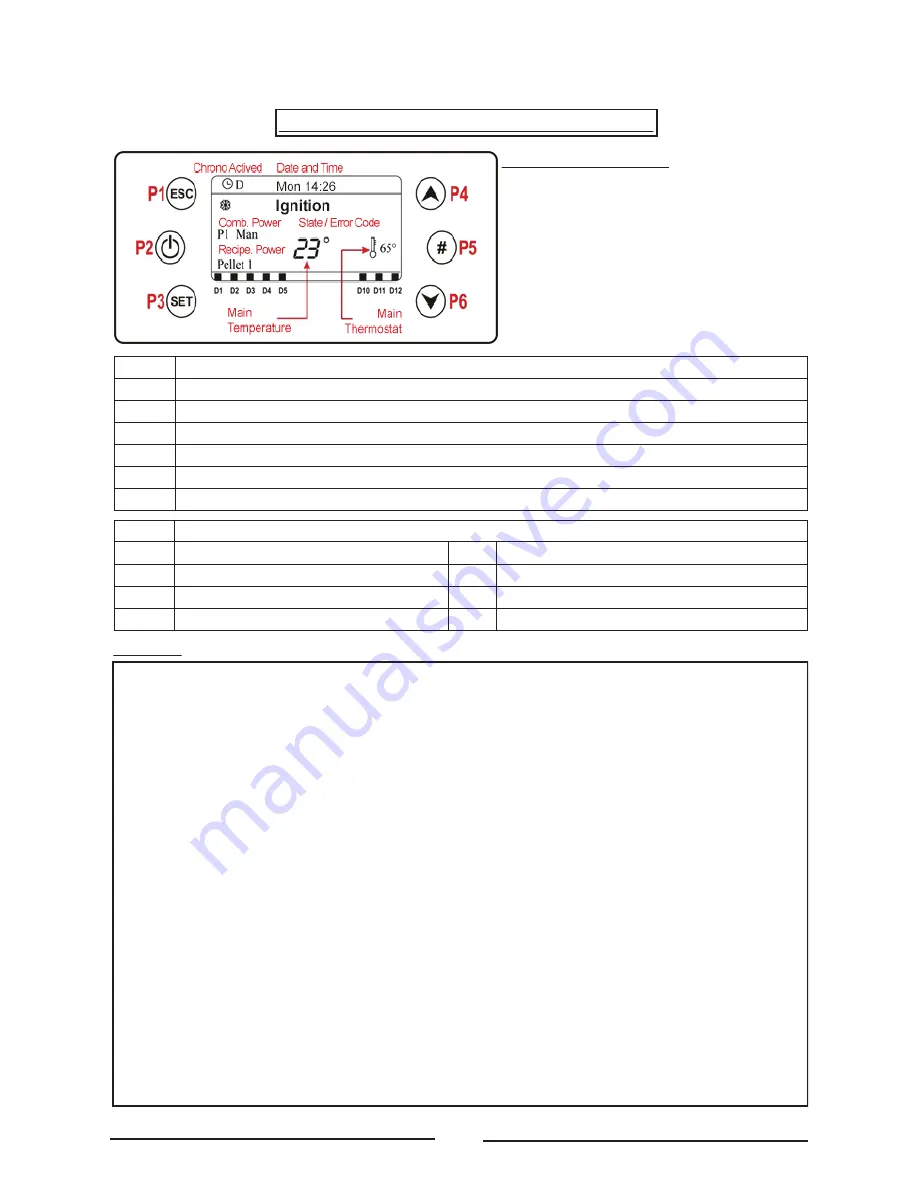

The main frame shows:

time and date, chrono activation, combustion

power and recipe, functioning state, error code,

main temperature, main thermostat,

summer/winter mode.

Button

Function

P1

P2

P3

P4

P5

P6

Exit Menu/Submenu;

Ignition and extinguishing (push for 3 seconds), Reset errors (push for 3 seconds), Enable/disable chrono;

Enter in User Menu 1/submenu, Enter in User Menu 2 (push for 3 seconds), Save data;

Enter in Visualizations Menu, Increase

Activation chrono time band

Enter in Visualizations Menu, Decrease

Led

Function

D1

D9

D2

D10

D3

D11

D5

D12

Auger ON

V2:

Pump 1 ON

R:

Igniter ON

Aux2:

Pump 2 ON

External Chrono reached

Lack of pellet

Local Room Thermostat reached

Sanitary water demand

Er01

- Security Error High Voltage 1. It may also intervene with the system off;

Er02

- Security Error High Voltage 2. It can only intervene if the Combustion fan is active;

Er03

- Extinguishing for low exhaust temperature or missing light in the brazier;

Er04

- Extinguishing for water over temperature;

Er05

- Extinguishing due to high exhaust temperature;

Er06

- Pellet Thermostat open (flame return from the brazier);

Er07

- Encoder Error. The error may occur due to lack signal from Encoder;

Er08

- Encoder Error. The error can occur due to problems of adjustment of the number of revolutions;

Er09

- Water pressure low;

Er10

- Water pressure high;

Er11

- Clock Error. The error occurs due to problems with the internal clock;

Er12

- Extinguishing for ignition failure;

Er15

- Extinguishing due to power failure for more than 50 minutes;

Er16

- RS485 communication error (Display);

Er17

- Adjusting the Air Flow Failed;

Er18

- No more Pellet in the bunker;

Er23

- Boiler probe or Back boiler probe or probe Buffer open;

Er25

- Engine cleaning brazier broken;

Er26

- Engine cleaning broken;

Er27

- Engine cleaning 2 broken;

Er34

- Depression below the minimum threshold;

Er35

- Depression above the maximum threshold;

Er39

- Sensor Flowmeter broken;

Er41

- Minimum air flow in Check Up is not reached;

Er42

- Maximum air flow exceeded;

Er44

- Open door error;

Er47

- Error Encoder Auger: missing signal Encoder;

Er48

- Error Encoder Auger: Auger regulation speed not achieved;

Er52

- Error Module I/O I2C;

Er57

- Test ’Forced Draught High’ in Check Up fail ;

Service

- Service error. It notifies that the planned hours of functioning is reached. It is necessary to call for service.

ALARMS

CONTROL PANEL: USE AND FUNCTIONS

Summary of Contents for PS 24

Page 13: ...13 Mareli Systems ...

Page 14: ...14 Mareli Systems ...

Page 15: ...15 Mareli Systems ...