installation instructions

MiniVent 1000

CAUTION: Do not use the #10 flat head sheet metal screws to install the trim ring in an acrylic hatch as this may

cause the hatch to crack.

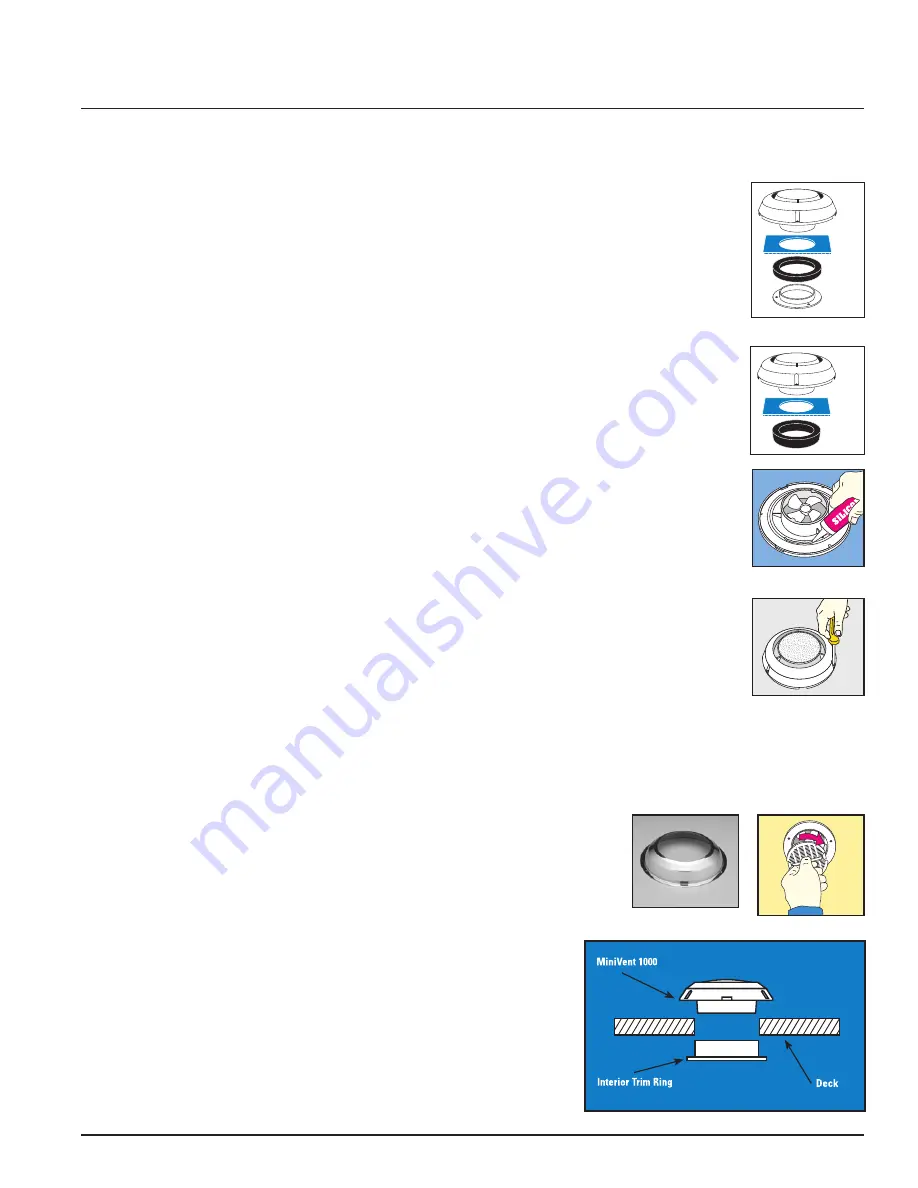

STEP FOUR: INSTALLING THE VENT UNIT

It is important to rough up the bonding surfaces between the base of the unit and hatch or deck to

get a good water-tight seal. Use 100 grit sandpaper around the edge of the installation hole and

around the bottom of the unit.

Deck Installation

There are three drain holes on the vent base; one is larger than the other two and should be

installed facing aft or towards the downward angle. It is labeled “AFT.” Bed the base of the unit

and the #6 pan head self-tapping screws provided with silicone or polyurethane sealant (regular

silicone seal is recommended for flat surfaces and polyurethane for a cambered deck). Place

the vent into the hole from the outside and attach it to the deck with the three #6 pan head self-

tapping screws provided. CAUTION: Use shorter length screws if your deck is less than 5/8"

(16mm) thick. DO NOT over-tighten the screws. Install the trim ring first, then the vent, using only

a HAND-HELD screwdriver.

Hatch Installation

Fastener holes are not required for hatch installations if the vent is to be glued to the hatch with

polyurethane. If fastener holes are to be used, drill 5/32" clearance holes completely through

the material.

To glue the vent to a hatch, apply a generous bead of polyurethane bedding compound around

the bottom of the vent. Rotate the vent into the hole as you are pressing it into place. This will

insure a proper seal. Polyurethane needs to cure thoroughly for maximum strength; depending

on the brand, this can take up to a few days. If you choose to use fasteners to install the vent,

use #6 machine screws with a Nylock nut and washer (not provided). Drill three holes all the

way through the acrylic hatch OVERSIZED to 5/32". Insert the machine screws all the way

through the 5/32" holes. When silicone sealer is applied to the machine screws, the use of an

oversized hole will create a shock absorber so the screws will not damage the hatch. Be sure

to apply silicone sealer to the base of the unit and also to the machine screws so that the

threads do not “weep” water below during wash down, rain or heavy spray.

Tighten the screws by hand (not a power-driver), and make them snug but not tight enough to crack the unit. Allow

silicone to cure thoroughly to insure a watertight seal. CAUTION: Do not use the #6 pan head screws provided with

this unit on a hatch installation as they may crack the hatch. Machine screws with clearance holes are required.

Install the trim ring (and optional spacer) first, then the vent, using only a HAND-HELD screwdriver.

FEATURES

An optional Nicro stainless steel cover (#N28830) is available for the MiniVent

1000. It attaches directly over the top of the vent with three #6 self-tapping

screws. When installing the stainless steel cover, be sure to align the drain

holes in the cover with those in the vent.

The MiniVent 1000 comes with a removable insect screen that attaches to the

shut-off damper. The screen is easy to install by grasping the fin in the

center and carefully twisting it on in a clock-wise motion. The screen

must be removed when opening the damper or you may break the tabs

on the damper. If the shut- off damper becomes difficult to operate,

apply a little silicone grease around the perimeter.

PROCESS

BLUE

RUBINE

RED

109

YELLOW

BLACK

INSTALLATION GUIDE INKS

22-Caulk Mini.ilp

PROCESS

BLUE

RUBINE

RED

109

YELLOW

BLACK

INSTALLATION GUIDE INKS

26-Screw Mini.ilp

ACRYLIC

HATCH

HATCH

SPACER

RING

PLASTIC

INTERIOR

TRIM RING

MINI-

VENT

MINI-

VENT

ACRYLIC

HATCH

HATCH

PROTECTIVE

RING