Plug & Test

TM

Smart Force & Torque Sensors

User’s Guide

1

Thank you…

Thank you for purchasing a Mark-10 Plug & Test

TM

remote sensor, designed for use with Mark-10 models

7i, 5i and 3i force/torque indicators.

With proper usage, we are confident that you will get many years of great service with this product. Mark-

10 sensors are ruggedly built for many years of service in laboratory and industrial environments.

This User’s Guide provides setup, safety, and operation

instructions for each individual sensor series. Instructions for

using models 5i and 3i indicators are available in their

respective user’s guides. For additional information or answers

to your questions, please do not hesitate to contact us. Our

technical support and engineering teams are eager to assist

you.

Before use, each person who is to use Mark-10 sensors

and indicators should be fully trained in appropriate

operation and safety procedures.

TABLE OF CONTENTS

OVERVIEW

.....................................................

…2

SAFETY / PROPER USAGE

..............................3

SETUP

................................................................4

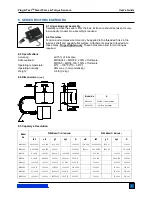

SERIES R01 FORCE SENSORS

.......................5

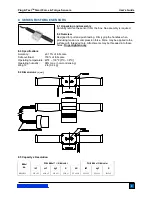

SERIES R02 FORCE SENSORS

.......................6

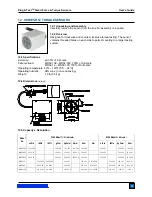

SERIES R03 FORCE SENSORS

.......................7

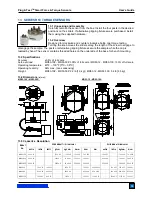

SERIES R04 FORCE SENSORS

.......................8

SERIES R05 FORCE SENSORS

.......................9

SERIES R06 FORCE SENSORS

.................... 10

SERIES R50 TORQUE SENSORS

................. 11

SERIES R51 TORQUE SENSORS

................. 13

SERIES R52 TORQUE SENSORS

................. 15

SERIES R53 TORQUE SENSORS

................. 16

SERIES R54 TORQUE SENSORS

................. 17

SERIES R55 TORQUE SENSORS

................. 18