Series 4 Digital Force Gauges

User’s Guide

11

7 SET POINTS

7.1 General Information

Set points are useful for tolerance checking (pass/fail), triggering an external device such as a motorized

test stand, or alarm indication in process control applications. Two limits, high and low, are specified and

stored in the non-volatile memory of the instrument and the primary reading is compared to these limits.

The results of the comparisons are indicated through the three outputs provided on the 15-pin connector,

thus providing “under”, “in range”, and “over” signaling. These outputs can be connected to indicators,

buzzers, or relays as required for the application.

7.2 Configuration

To configure set points, select

Set Points

from the menu. The screen appears as follows:

Either one, two, or none of the set points may be enabled. To toggle between the tension and

compression directions, press the

DIRECTION

key.

If two set points have been enabled, they are displayed in the upper left corner of the display. If only one

set point has been enabled, the word “OFF” appears in place of the value. If no set points have been

enabled, the upper left corner of the display will be blank.

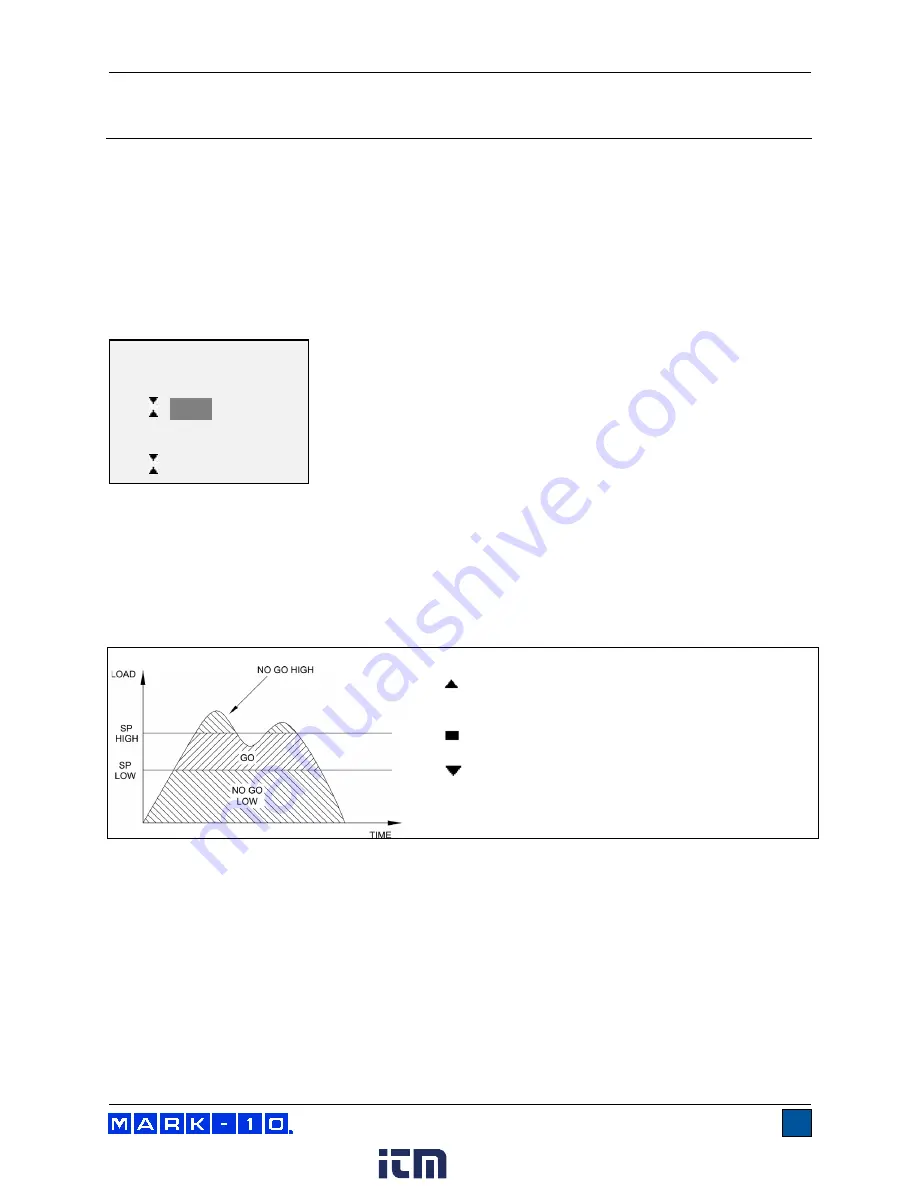

When set points are enabled, the following indicators are shown to the left of the primary reading:

– the displayed value is greater than the upper

force limit (NO GO HIGH)

– the displayed value is between the limits (GO)

– the displayed value is less than the lower force

limit (NO GO LOW)

Note:

Set point indicators and outputs reference the displayed reading, not necessarily the current live

load.

SET POINTS

Upper Disabled

* Upper Enabled

5.000

Lower Disabled

* Lower Enabled

3.500

www.

.com

information@itm.com

1.800.561.8187