Series TT02 Digital Torque Tool Testers

User’s Guide

13

10.2 Settings

The display appears as follows:

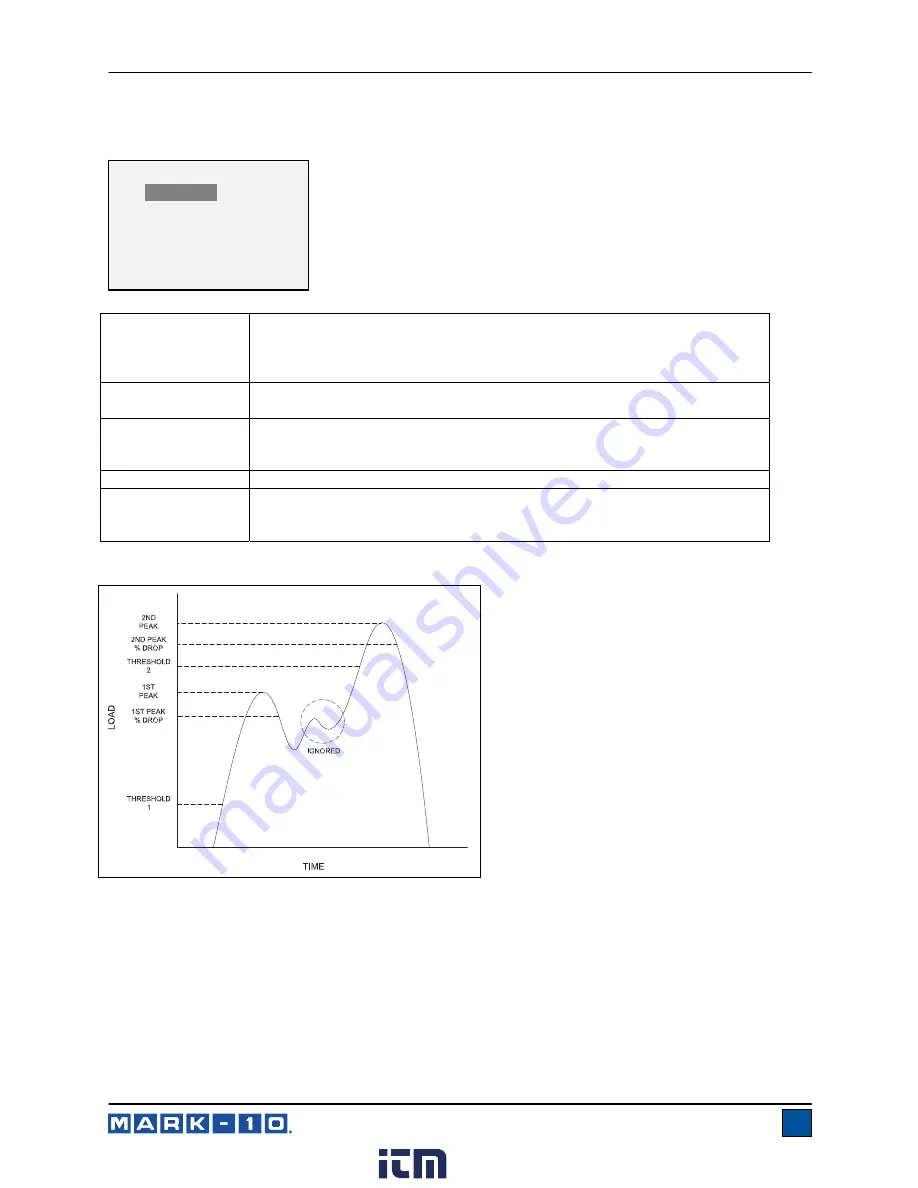

Thresholds and percentage drops are illustrated below:

10.3 Auto Output Settings

Select the output type. Select RS-232/USB and/or Mitutoyo outputs, and select First and/or Second

peaks. The display appears as follows:

Threshold 1

Sets the percentage of full scale at which the first/second peak detection

feature becomes active. This threshold is provided to ignore peaks that can

occur during sample loading and unloading. Available settings:

1-90%

, in

1% increments between 1-5%, and in 5% increments between 5-90%.

Percentage Drop 1

Identifies the first peak via detection of a specified percentage drop from

peak.

Threshold 2

Same as with Threshold 1, but refers to a percentage of full scale beyond

the first peak. For example, for a 50 lbFin capacity tester, if the first peak is

20 lbFin, and Threshold 2 is set to 15%, the threshold is equal to 27.5 lbFin.

Percentage Drop 2

Same as Percentage Drop 1, for the second peak.

Auto Zero Delay

Sets the time delay before the primary and peak readings are zeroed.

Available settings:

1-60 sec

., in 1 sec. increments between 1-5 sec., and in

5 sec. increments between 5-60 sec.

PEAK SETTINGS

Thresh. 1:

5 %

% Drop 1: 10 %

Thresh. 2: 5 %

% Drop 2: 10 %

Auto Zero Delay

3 sec.

www.

.com

information@itm.com

1.800.561.8187