9

4.0 INSTALLATION

1) Damage Inspection:

Reporting shipping damage is the responsibility of the purchaser.

Do not discard packaging if filing a freight damage claim. Upon receipt of steamer

immediately inspect the exterior of packaging for damage. Remove wrapping. Inspect the

exterior of the

Altair II

for visible shipping damage.

2) Unpacking / removal from pallet:

To remove the steamer from the pallet, carefully cut

the strapping.

3) Legs / caster installation:

Install 4 legs or casters (shipped inside the steamer) into the

threaded mounting holes located on the base of the unit. If casters are supplied, locking

casters should be on the front of the steamer.

4) Vent pipe installation (double & single compartment steamers):

Steamers come with

the vent piping in rear of unit completely assembled. Two 90° elbows are shipped loose

for your convenience that may be useful in running a drain line to your floor trough (if

applicable). DO NOT BLOCK VENT PIPE.

5)

Make sure the pan racks, water reservoir cover and standpipe installed inside the

steamer have not become dislodged during shipping.

6) Physical location of steamer:

98% of all maintenance and service can be done from

the front or left side. Some local codes may require installation under ventilation, but

ventilation is not required in most cases. A minimum of 4” clearance from adjacent

equipment on the left side and rear is recommended.

7) Electrical hookups:

The access hole to electrically wire your steamer is located in the

bottom right corner (facing the back of the steamer) on the rear panel. Your electrician

may install a cord set to make the steamer more portable or the unit may be hard-wired.

Please follow local codes when installing the cord set.

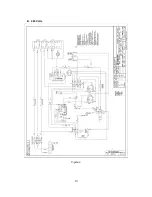

8) Electrical Diagrams:

The electrical diagrams are located on the inside of the left side

access panel.

9) Water hookup:

Steamer requires ½” water line. Termination is ¾” male garden hose

connection. Make sure waterline is flushed to remove grit and soldering particles prior to

connecting steamer. Dirty water lines may affect solenoid operation.

Double (stacked) compartment steamers

require separate water connections, which

may be manifolded. Inadequate water supply may cause one steamer not to fill properly

when both steamers are turned on at the same time. If that happens turn on one steamer

a few minutes after the first.

Do not connect to de-ionized water. Probes will not sense the level of the water.

Recommended water pressure is 30 – 35 lbs.

10) Recommended water quality:

This steamer does not require water filtration in line with

the steamer’s water line. However, it is important to properly drain and clean your water

reservoir at least daily (see 6.0 Cleaning Guidelines in this manual).

NOTE:

A qualified electrician must perform all electrical hookups and meet all local codes.

Installation is the responsibility of the purchaser.

NOTE:

Stacked units will require 2 separate electrical connections.

CAUTION:

Flush incoming water line prior to connecting to steamer. Debris in water lines may

cause solenoid valve to malfunction. If solenoid valve is stuck open water must be turned off at

the source.

NOTE:

Water level probes will not sense water level if steamer is connected to a de-ionized water

or reverse osmosis system.