8

SERVICE CONNECTIONS

(continued)

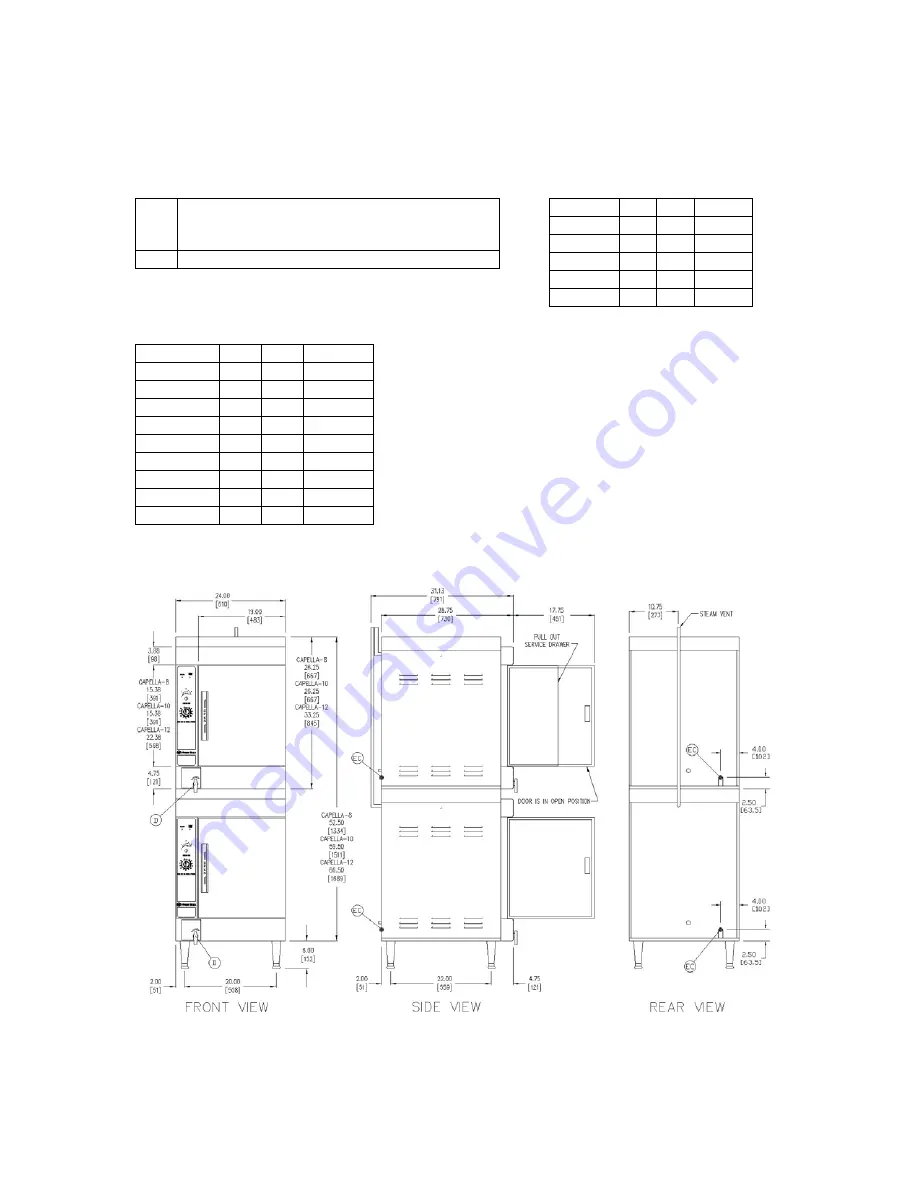

Models: Capella – 8, Capella – 10 & Capella – 12

Capella Service Connections:

ELECTRICAL (Capella - 4) 60 Hz

EC

Electrical Connection – 1 1/8” knock-out hole

for electrical connection. Rating provided on

data label.

D

Drain – A 6 ft. removable drain hose

Voltage

pH

kW

Amps

208

1

8

39

240

1

8

33

208

3

8

22

240

3

8

19

480

3

7.2

9

ELECTRICAL (Capella - 6) 60 Hz

Voltage

pH

kW

Amps

208

1

8

38.5

240

1

8

33.3

208

3

8

22.2

240

3

8

19.3

208

1

9.8

47

240

1

9.8

41

208

3

9.8

27

240

3

9.8

24

480

3

9

12

NOTES:

4” clearance left mandatory, right and rear is recommended.

Location near a floor drain is recommended.

Steamer sizes can be mix matched. Two 4-pan (Capella-4)

stacked together makes an 8-pan steamer (Capella-8), a 4-

pan and 6-pan (Capella-4 & -6) stacked together makes a 10-

pan steamer (Capella-10), and two 6-pans (Capella-6)

stacked together makes a 12-pan steamer (Capella-12).

Refer to the electrical charts (above and to the left) for proper

voltage requirements for each steamer.

Each compartment, stacked or single, requires a separate

electrical connection.