METAL X PRINTER USER GUIDE

60

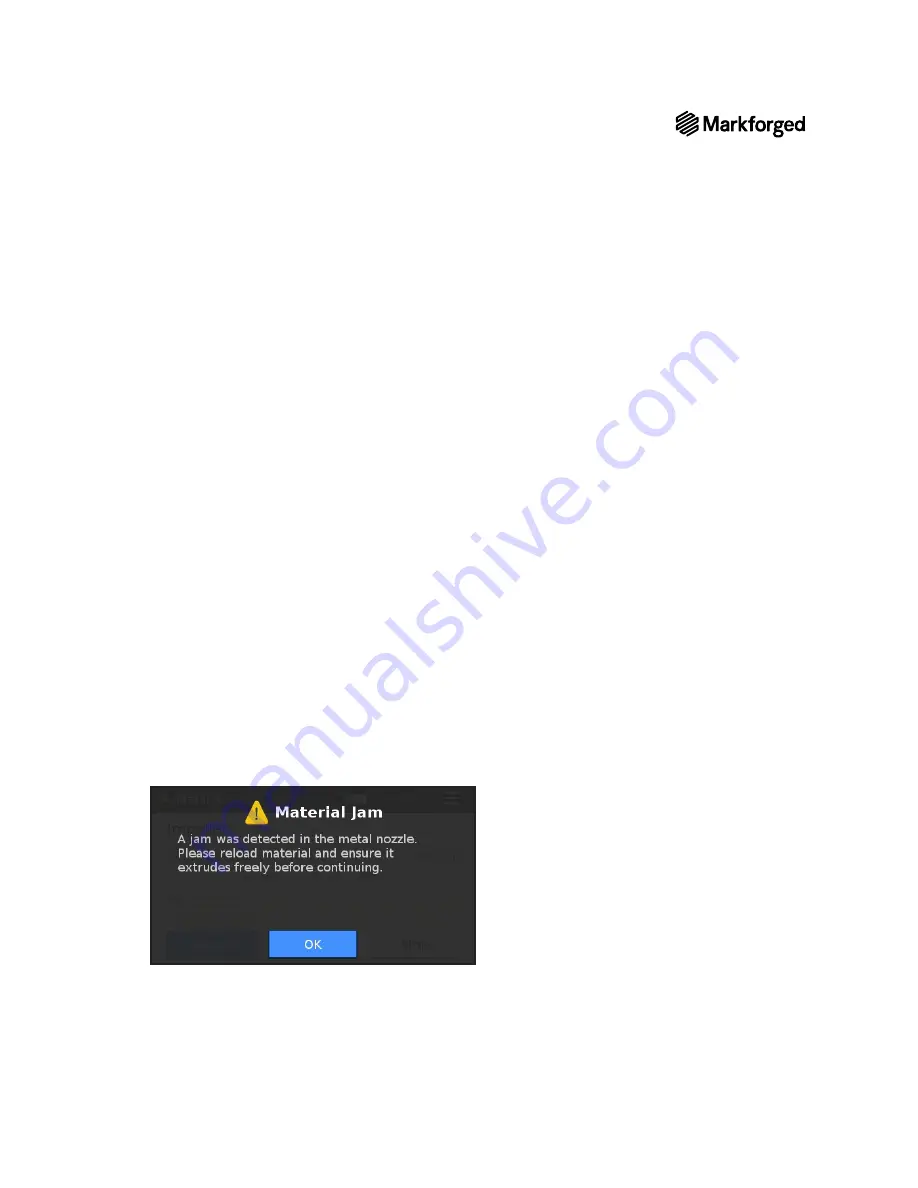

CLEARING METAL MATERIAL JAMS

Supplies

●

Tweezers

●

Anti-Seize

●

Wire brush (included in accessory kit)

●

Nozzle wrench (included in accessory kit)

●

Purge rod (included in accessory kit)

●

2mm hex key

●

2.5mm hex key

●

Replacement metal nozzle

●

Replacement feed tube(s)

A printer jam occurs when buildup in the print head material pathway prevents proper extrusion from the nozzle.

In the event of a printer jam, follow these steps one at a time, as needed, to locate and correct the cause of the

jam. The majority of printer jams can be resolved without canceling your print in progress.

After each section of this troubleshooting workflow, resume the print. If the jam has been remedied, you are

finished troubleshooting. If not, proceed to the next section. The

●

Unload and reload print material; clean nozzle tip.

●

Remove nozzle; clear material pathway using purge rod; reinstall old nozzle.

●

Install replacement nozzle.

●

Remove and replace lower feed tube immediately if jam persists, otherwise after print completes.

UNLOAD AND RELOAD PRINT MATERIAL

Begin troubleshooting your printer jam by unloading and reloading the filament.

1.

Follow the instructions in the

Unloading Metal Filament

section to clear the loaded metal filament from

the print head.