71

METAL X PRINTER USER GUIDE

5.

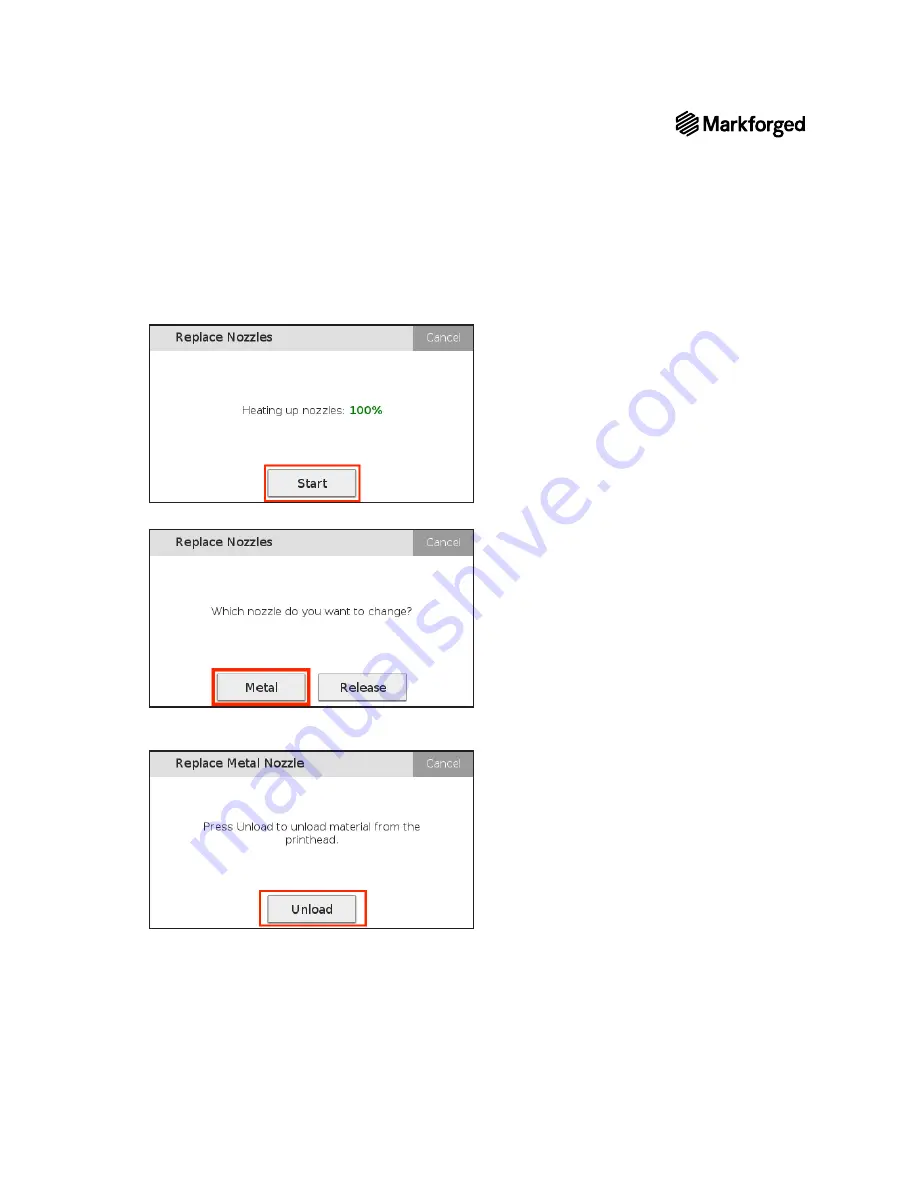

Both nozzles will begin to heat. Press

Start

when the nozzles are 100% heated.

6.

Select

Metal

as the type of nozzle you are replacing.

7.

Select

Unload

to retract the metal material from the print head. Doing so will ensure that excess material

does not enter the threads and nozzle channel.